Novel non-Newtonian fluid micro-coating system and control method

A non-Newtonian fluid and micro-coating technology, which is applied in the direction of flow control, non-electric variable control, flow control using electric devices, etc., can solve the problem of low reliability, complex modeling and control of non-Newtonian fluid, and inability to maintain high consistency and uniformity and other issues to achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

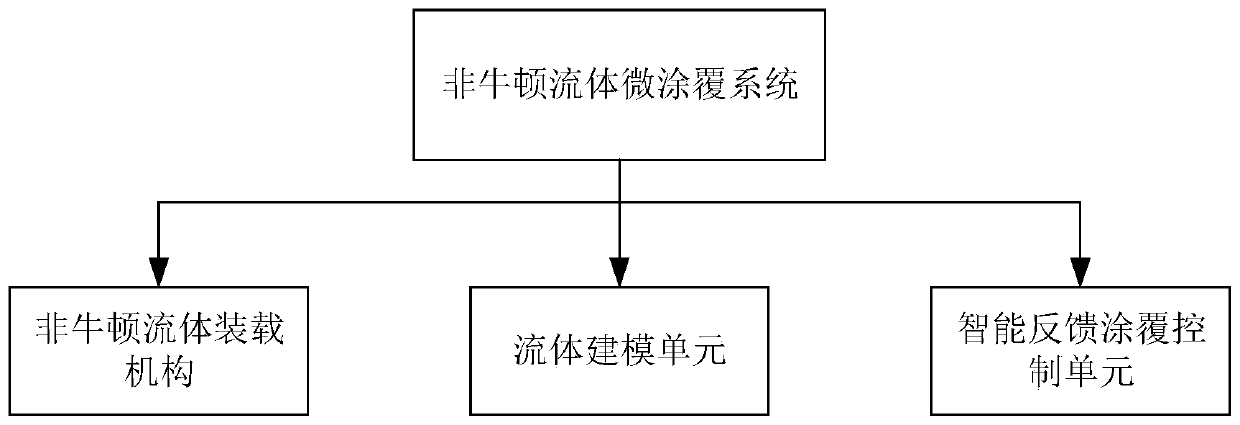

[0051] A new type of non-Newtonian fluid micro-coating system, such as figure 1 As shown, including non-Newtonian fluid material loading mechanism, fluid modeling unit, intelligent feedback coating control unit;

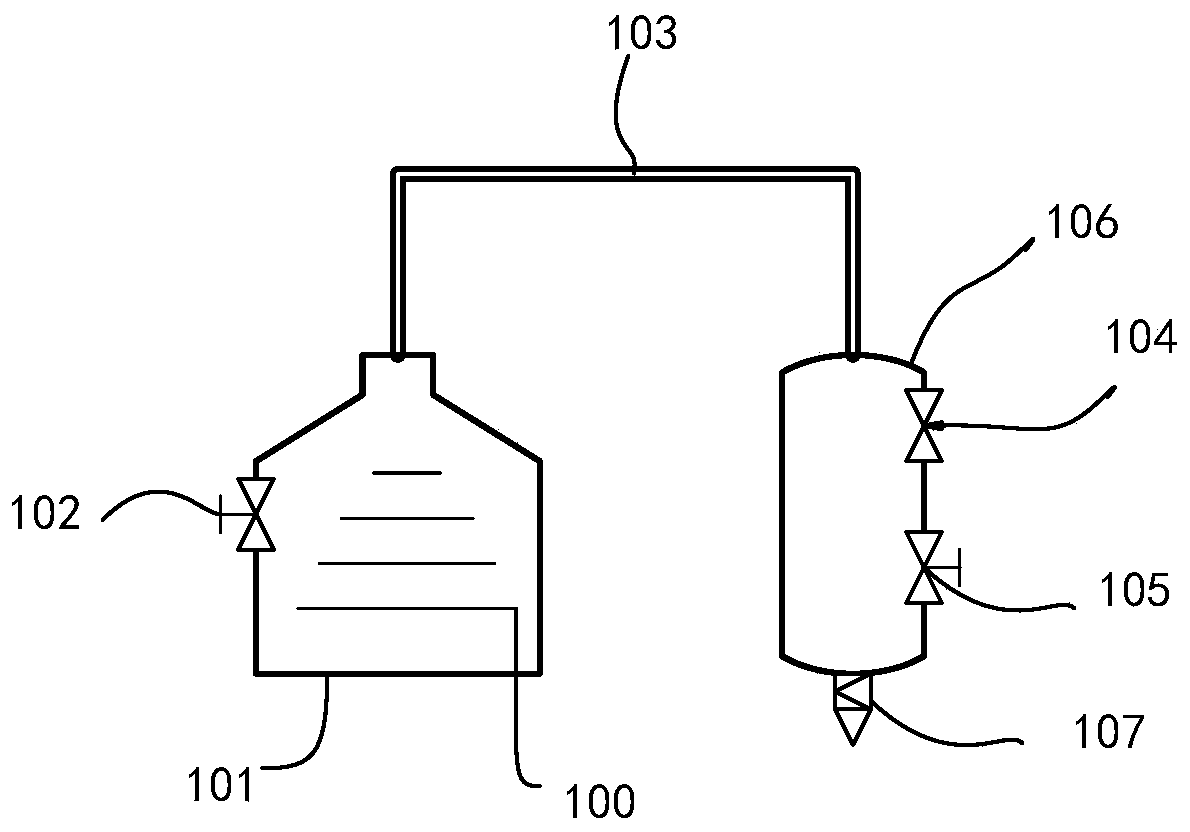

[0052]The non-Newtonian fluid material loading mechanism includes a storage pressure device and a nozzle device, the storage pressure device is connected to the nozzle device through a feed pipeline; the storage pressure device includes a storage pressure barrel 101 and a first air pressure control unit 102, The storage pressure tank 101 controls the air pressure of the storage pressure tank through the first air pressure control unit 102 of the storage pressure tank; The control unit 105 and the nozzle 107 used for the spraying outlet, the nozzle 107 is a rigid pipeline, the diameter of the nozzle is smaller than the diameter of the material cylinder; the first air pressure control unit 102 is a pressure regulating valve, that is, a pressure valve, and the second ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com