Bare core with electromagnetic shielding structure

An electromagnetic shielding structure and bare core technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of high cost and complicated electromagnetic shielding structure process, and achieve the effect of low cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

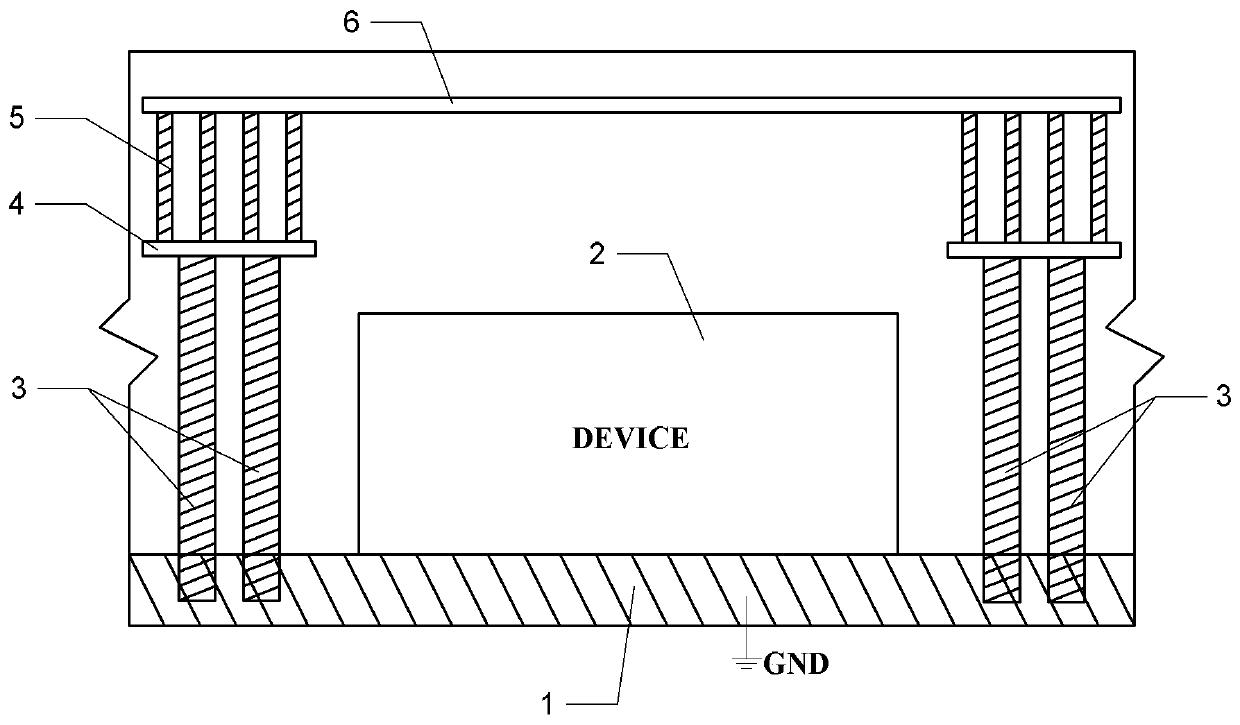

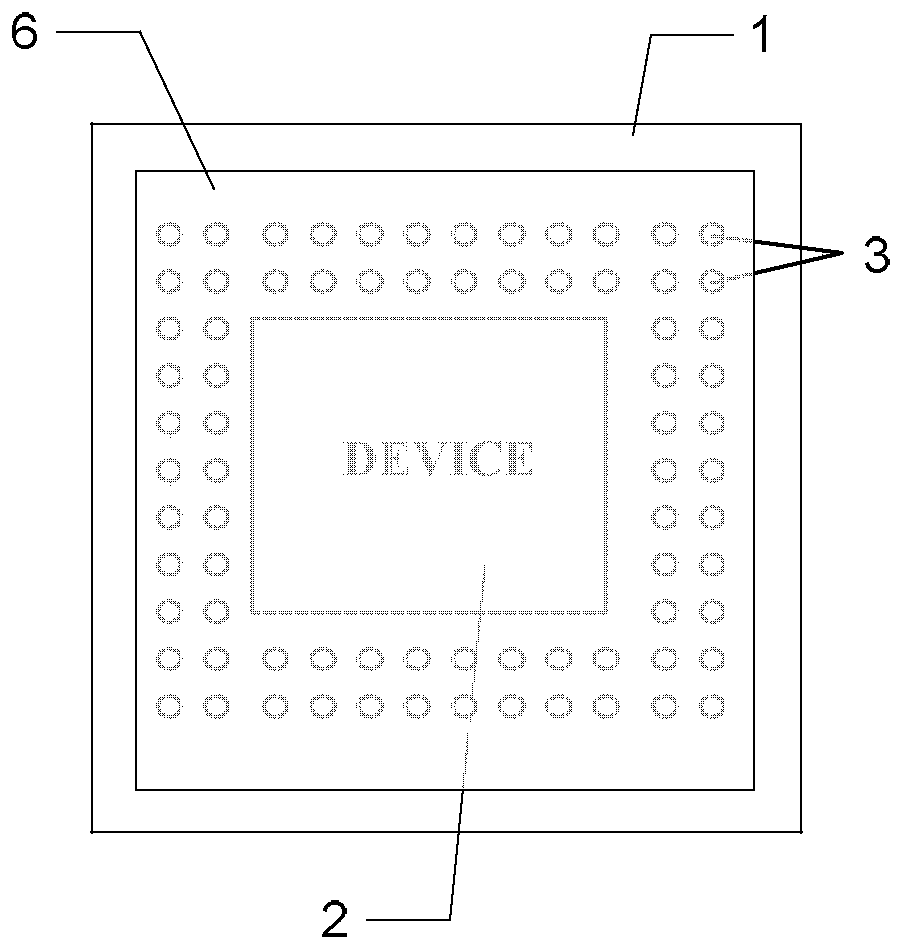

[0031] Specific implementation mode one: the following combination figure 1 , 2 and 4 illustrate this implementation mode. The bare core with an electromagnetic shielding structure described in this implementation mode is constructed using DSV technology, including a P-type substrate 1, an integrated circuit device DEVICE2, a deep silicon via DSV3, an intermediate metal layer 4, and a metal layer through The hole via5 and the top metal layer 6 are physically connected to the ground GND of the P-type substrate 1;

[0032] The integrated circuit device DEVICE2 is built on the P-type substrate 1; the multi-layer deep through-silicon via DSV3 is built tightly and orderly around the integrated circuit device DEVICE2, and the deep through-silicon via DSV3 is filled with a high-conductivity conductor, and the deep through-silicon via DSV3 The bottom end of the deep through-silicon via DSV3 penetrates the active layer of the P-type substrate 1, and the top of the deep through-silicon...

specific Embodiment approach 2

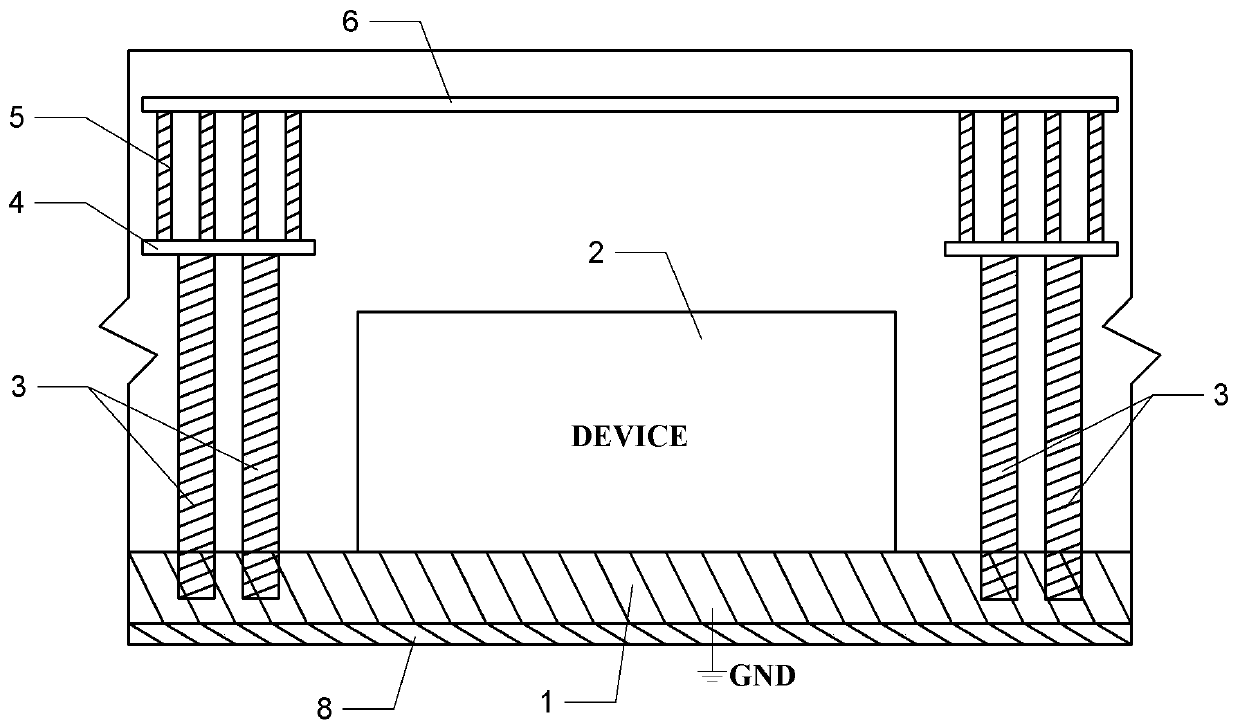

[0042] Specific implementation mode two: the following combination image 3 This embodiment will be described. The difference between this embodiment and Embodiment 1 is that the back gold 8 is bonded to the back of the P-type substrate 1 through the prepared conductive resin layer.

[0043] On the back of the P-type substrate (P++Substrate), make a layer of conductive resin and then glue the backside metal 8 (BacksideMetal). The metal material of the backside gold 8 is such as but not limited to: aluminum (Al), gold (Au ), silver (Ag), copper (Cu), adding this piece of metal can further strengthen the anti-electromagnetic ability of the structure.

specific Embodiment approach 3

[0044] Specific implementation mode three: the following combination Figure 5 Describe this embodiment mode. The difference between this embodiment mode and Embodiment 1 or 2 is that it also includes the sub-top metal layer 7, and the sub-top metal layer 7 is connected to the top metal layer 6 and the middle metal layer 4 through multiple parallel rows. The metal layer is connected via via5.

[0045] If the thickness of the top metal layer 6 cannot meet the minimum requirement of the magnetic penetration depth at the high resonant frequency, the second top metal layer 7 can also be reserved, and the interlayer oxide ILO ( To prevent short circuit between the two), the metal layer through hole via5 is constructed in the interlayer oxide layer to realize the electrical connection between the top metal layer 7 and the top metal layer 6; the deep silicon via DSV3 passes through one or more intermediate metal layers 4 It is connected to the second top metal layer 7, and other con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com