System and method for driving semiconductor laser based on DCDC power supply module or chip

A technology for power modules and lasers, applied in semiconductor lasers, devices for controlling laser output parameters, lasers, etc., can solve the problems of high power consumption and difficult external heat dissipation design, achieve low power consumption, reduce overall power consumption, and reduce difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

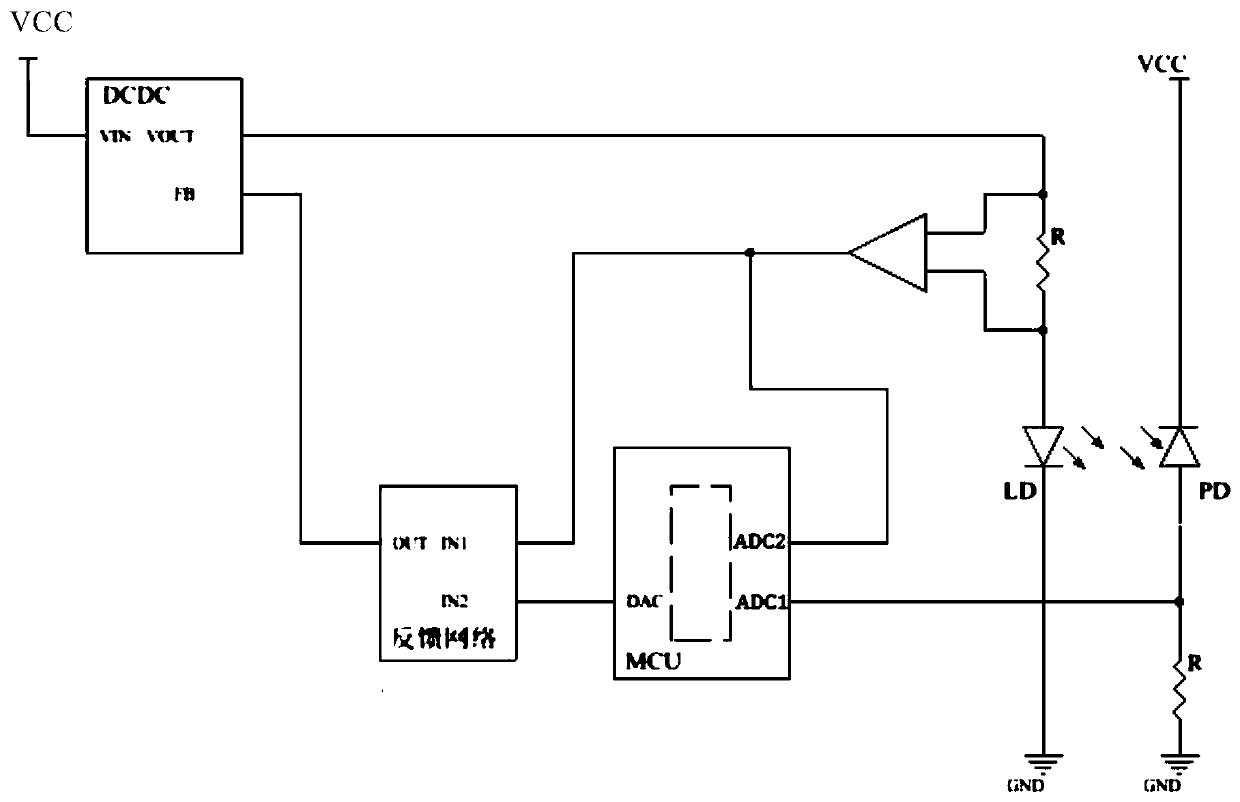

Embodiment 1

[0051] The driving part of this embodiment is composed of a DCDC power supply module or chip, and the sampling feedback and control part is composed of a current sampling circuit, a feedback network and an MCU control unit.

[0052] The DCDC power module or chip is used as the current drive source of the semiconductor laser to convert the power supply voltage of the module into the actual working voltage of the laser under specified working conditions. Of course, with the different requirements of the output optical power, this voltage will also change instead of a fixed value. .

[0053] The current sampling circuit includes two circuits, one of which is a driving current acquisition circuit, which collects the driving current of the semiconductor laser and converts it into a voltage signal; the other is a backlight current acquisition circuit, which collects the backlight current of the laser component and converts it into voltage signal.

[0054] As a control unit, the MCU...

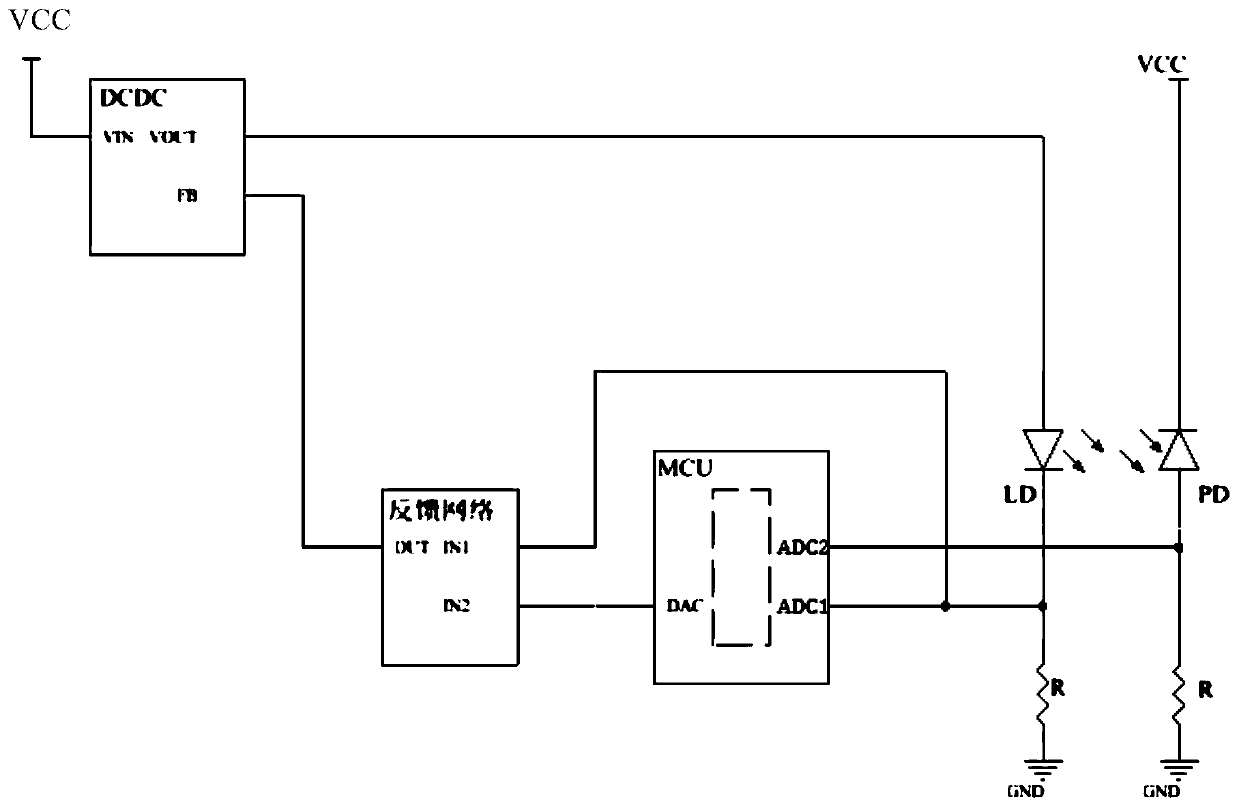

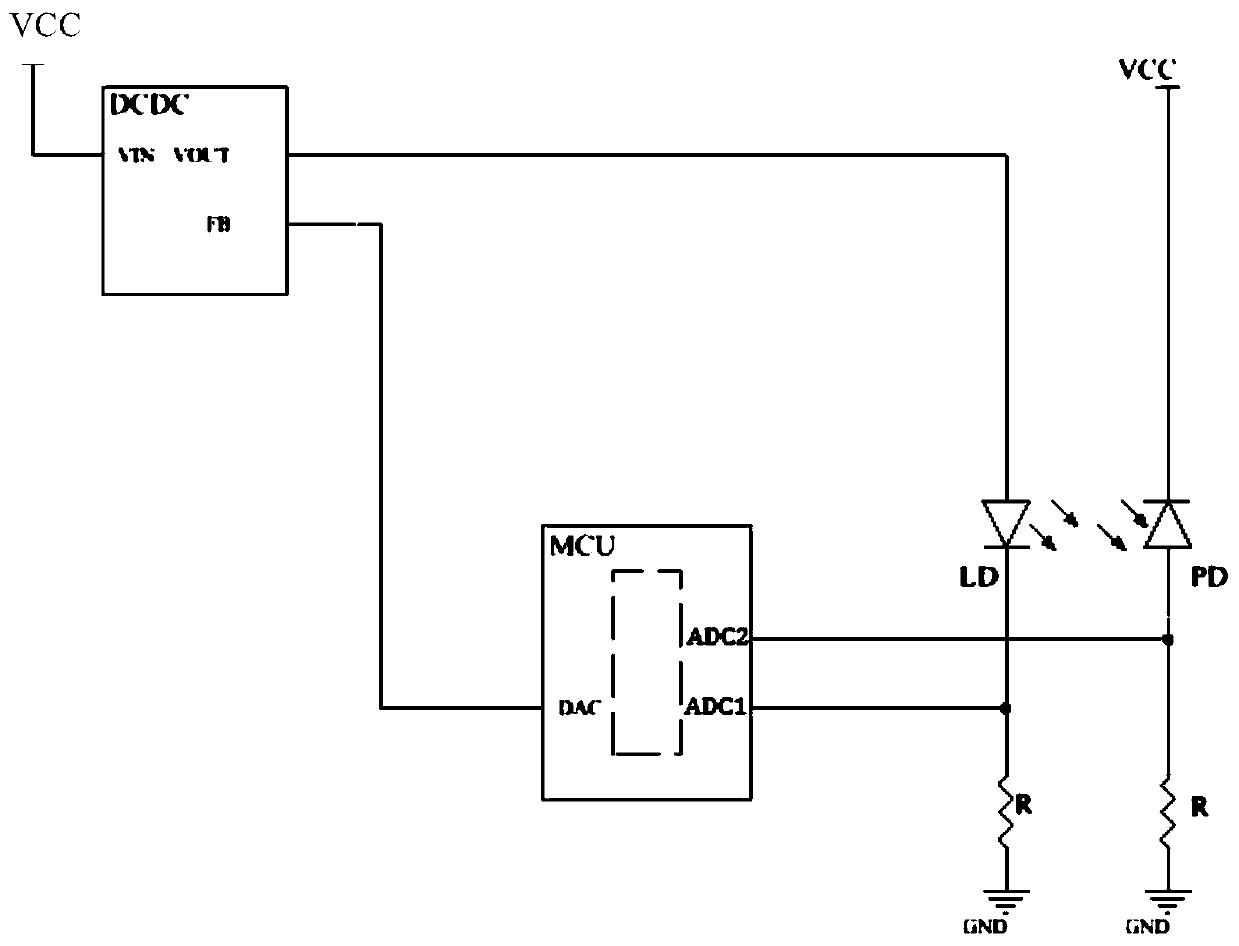

Embodiment 2

[0069] The driving part of this embodiment is composed of a DCDC power supply module or chip, and the sampling feedback and control part is composed of a current sampling circuit and an MCU control unit.

[0070] The DCDC power module or chip is used as the current drive source of the semiconductor laser to convert the power supply voltage of the module into the actual working voltage of the laser under specified working conditions. Of course, with the different requirements of the output optical power, this voltage will also change instead of a fixed value. .

[0071] The current sampling circuit includes two circuits, one of which is the driving current acquisition circuit, which collects the driving current of the semiconductor laser and converts it into a voltage signal; the other is the backlight current collection circuit, which collects the backlight current of the laser component and converts it into a voltage Signal.

[0072] As a control feedback unit, the MCU monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com