Steady-state sesame salt

A technology of sesame salt and stabilization, applied in the field of condiments, can solve problems such as uneven taste of the upper and lower layers, affect the appearance and taste, and flavor attenuation, so as to meet the requirements of food quality, delay the process of oxidative rancidity, and meet the requirements of good food quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

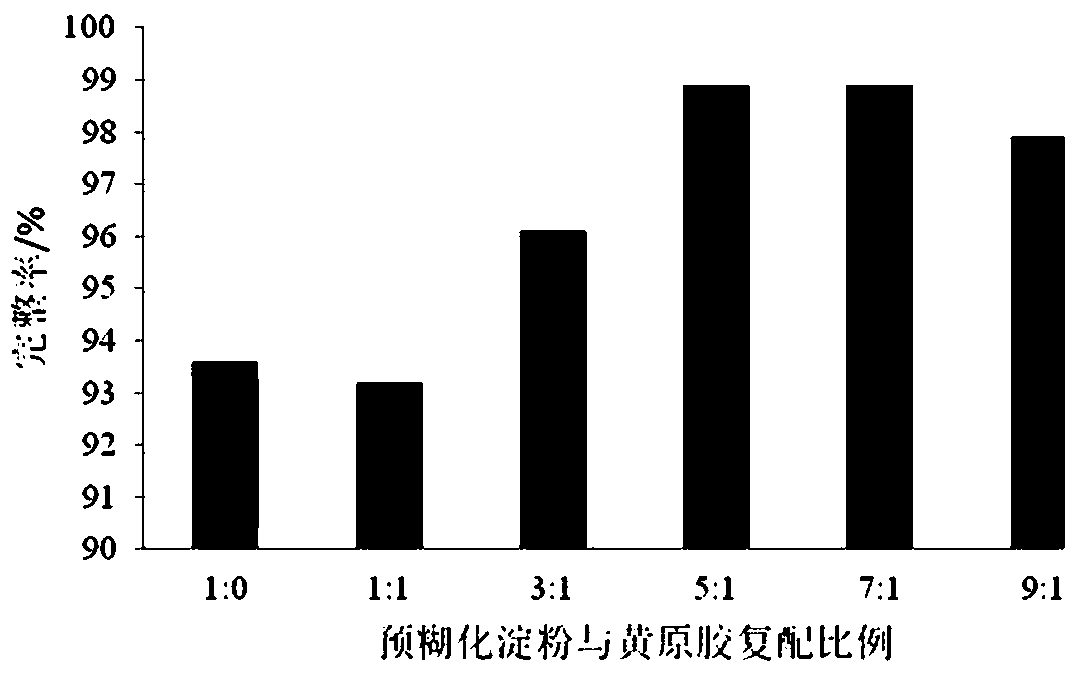

[0068] The stabilized sesame salt provided by this application, in parts by weight, its formulation raw materials include: 100 parts of sesame, 2-8 parts of starch (pregelatinized starch), 1-3 parts of edible salt, edible gum ( Such as xanthan gum) 0.3~3.0 parts.

[0069] The specific preparation method comprises the following steps:

[0070] (1) Pretreatment of sesame raw materials

[0071] After cleaning and drying, the sesame raw materials are fried in an electric heating drum wok. It is better that the fried sesame has a unique burnt aroma and does not become mushy. The temperature of the frying output is 165°C;

[0072] (2) Granulation

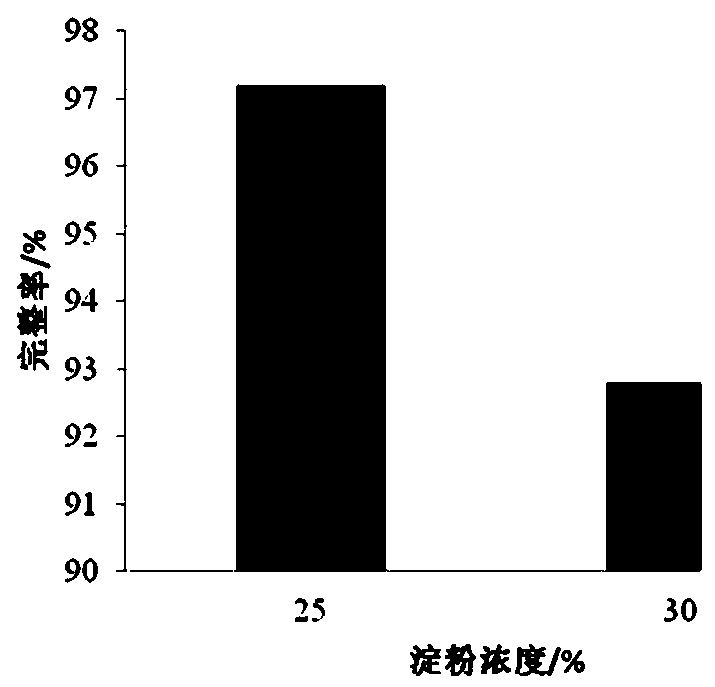

[0073] In the 25% concentration starch solution, mix sesame, edible gum and edible salt evenly, use a granulator to directly granulate, and process into spherical granules with a diameter of 6-8mm;

[0074] (3) Dry molding

[0075] The molded sesame salt granules are dried and solidified by a staged drying method, and the specific sta...

Embodiment 2

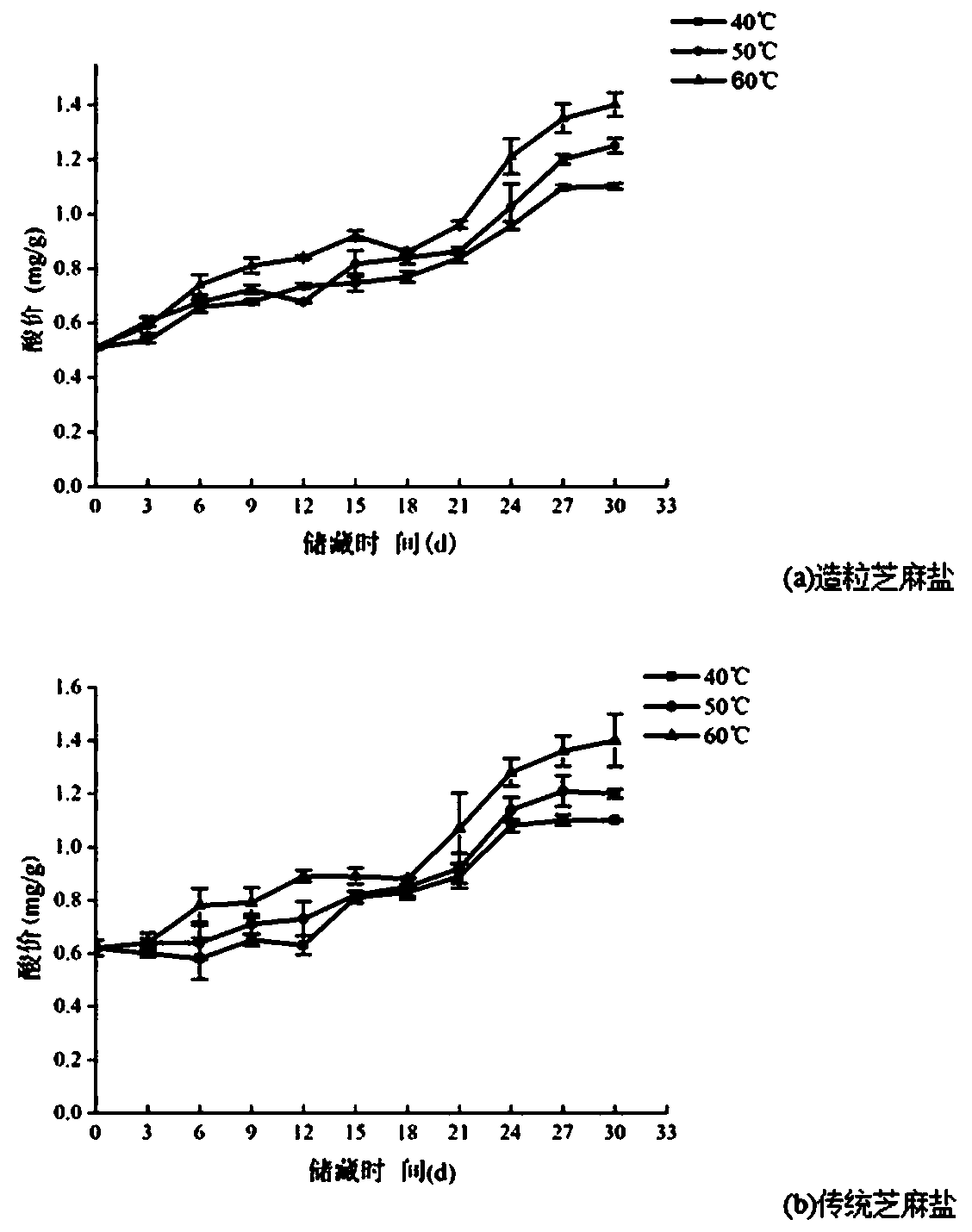

[0096] With reference to the experimental results of Example 1, this example prepared specific stable sesame salt granules (spherical granules with a diameter of about 6-8mm), and its formula raw materials were: white sesame 100g, cassava pregelatinized starch 7g, xanthan gum 1.4g , edible salt 1.5g. A total of 28g of water was used in the preparation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com