Method for preparing defect-free MOF-801 film by small seed crystal induced film formation-surfactant post-modification strategy and application thereof

A technology of MOF-801 and surfactant, applied in the field of membrane separation, to achieve the effect of multiple separation possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0036] 1. Preparation of MOF-801 seed crystal and preparation of seed crystal layer

[0037] 1.1 Preparation of MOF-801 seed crystals

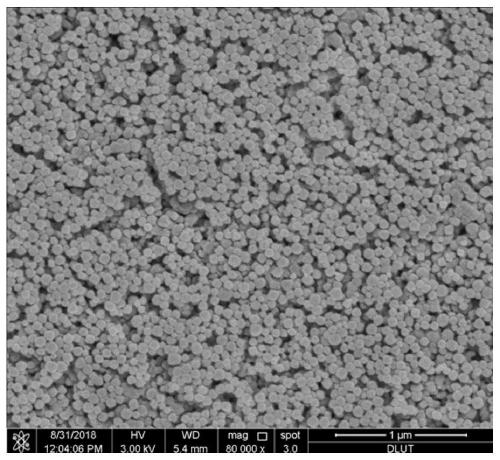

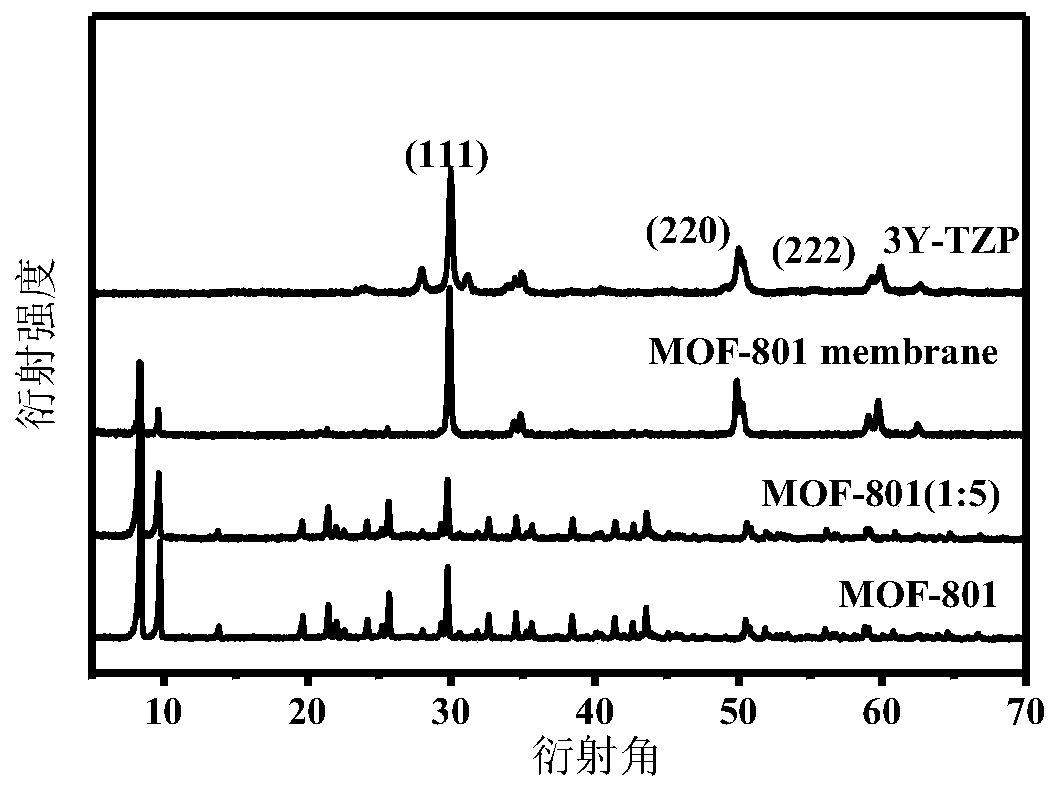

[0038] Fumaric acid (0.405g, 3.5mmol) and ZrOCl 2 ·8H 2 O (0.23g, 0.70mmol) was dissolved in a mixture solvent of DMF / formic acid (35mL / 5.3mL), mixed evenly, poured into a reaction kettle, and reacted at 120°C for 24 hours. Colorless crystals were collected and washed three times with 5 mL of fresh DMF. The solid was then dried under vacuum at 150 °C for 24 hours to obtain an activated sample. It is 69nm ( figure 1 ). X-ray diffraction confirmed that it was consistent with the diffraction data of the original MOF-801 ( figure 2 ).

[0039] 1.2 Preparation of MOF-801 seed layer

[0040] Put the pre-prepared ceramic carrier (sheet or hollow fiber tube) into the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com