Wear-resistant part with space latticed ceramic-metal composite layer and preparation method thereof

A technology of ceramic metal and space grid, which is applied in the field of wear-resistant composite materials, can solve the problems of block shedding, limited strength and wear resistance of the composite layer, and the reduction of the volume fraction of ceramic particles in the composite layer. Excellent impact resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

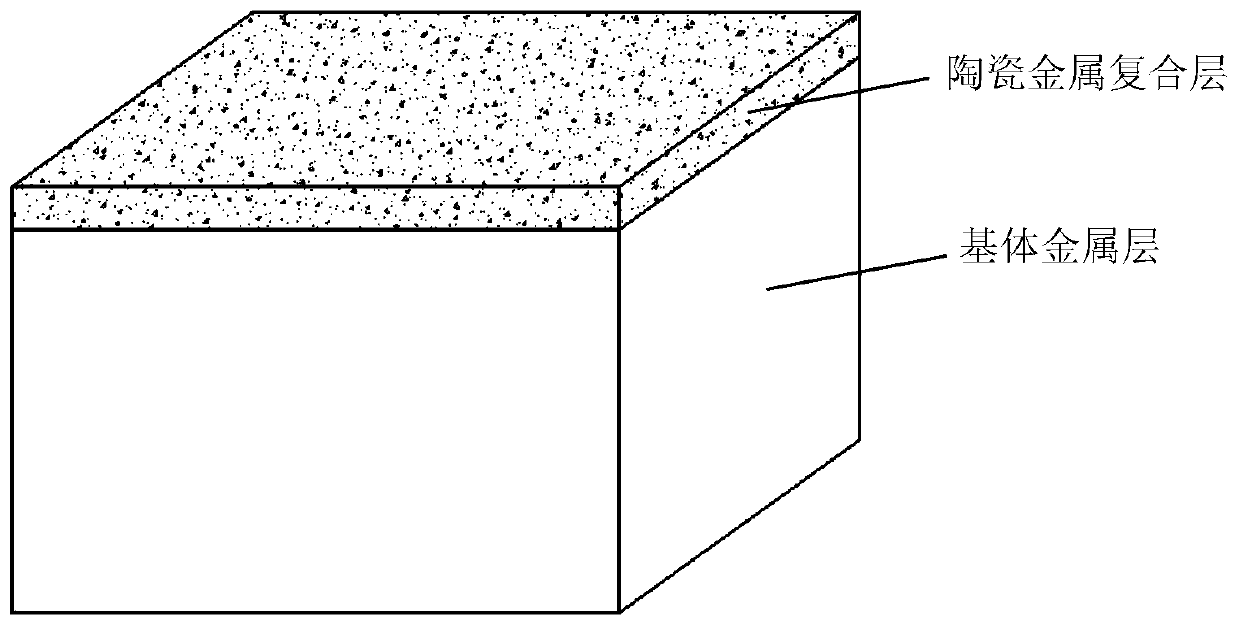

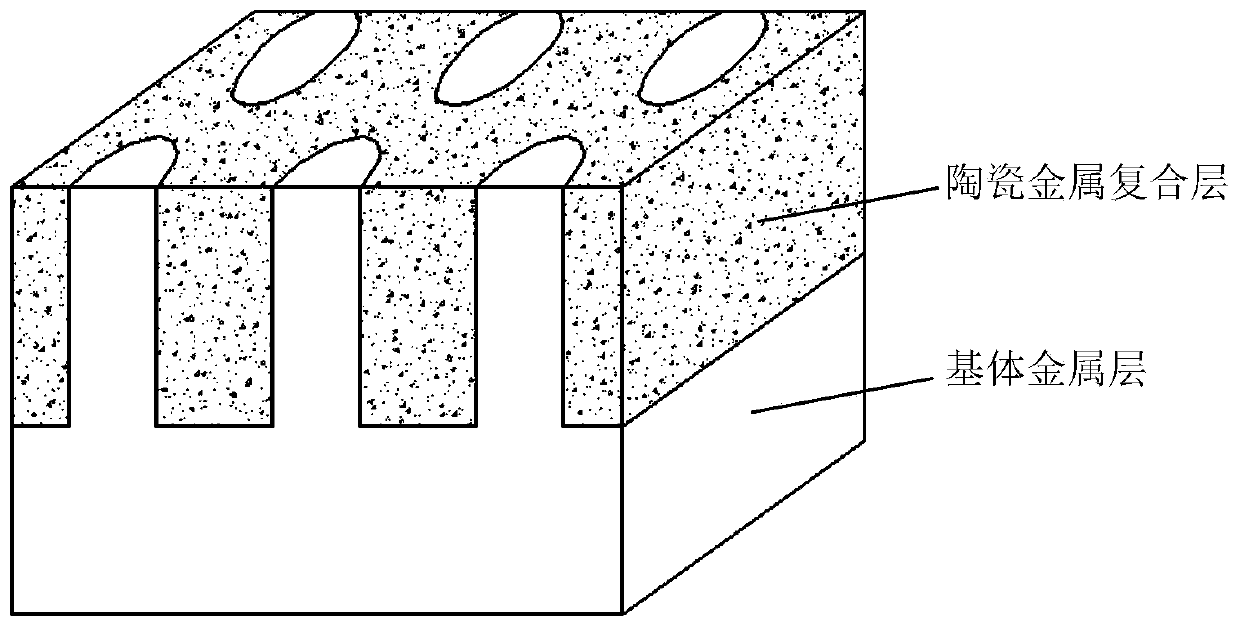

[0036] The preparation method of the wear-resistant part with the space grid shape ceramic metal composite layer of the present invention comprises the following steps:

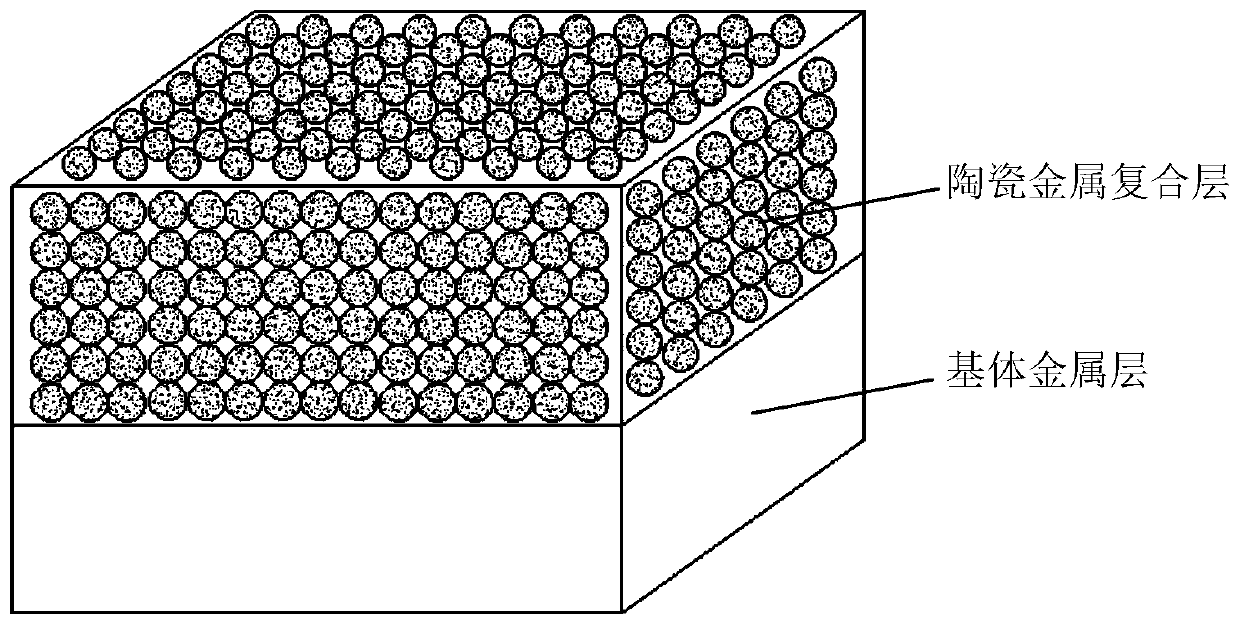

[0037] Step (1): using a binder to agglomerate the dispersed ceramic particles into a spherical ceramic preform, and the interior of the ceramic preform is formed by accumulation of ceramic particles to form interconnected pores;

[0038]Step (2): The spherical ceramic preform in step (1) is molded into a ceramic block by using a mesh metal outer frame or by using a binder and a ceramic block mold, then drying the ceramic block, and then drying the dried ceramic block The block is placed in the sand mold cavity of the wear-resistant part;

[0039] Step (3): Casting the matrix molten metal into the sand mold cavity, and obtaining a wear-resistant part with a space-grid-shaped ceramic-metal composite layer after forming.

[0040] The above-mentioned step (2) specifically includes the following steps: (2a) when...

Embodiment 1

[0045] The preparation of embodiment 1 wear-resistant hammer head

[0046] Step 1: Pretreatment of Ceramic Particles

[0047] The surface of the zirconium corundum ceramic particles with a particle size of 1.0-2.0mm and 2.0-4.0mm is subjected to nickel-plating treatment, and the mass ratio of the zirconium corundum ceramic particles with a particle size of 1.0-2.0mm and 2.0-4.0mm is 5:5 . The process of nickel plating includes the processes of surface treatment and plating.

[0048] Step 2: Preparation of ceramic preform

[0049] Mix the phenolic resin and the above-mentioned dispersed ceramic particles evenly, so that the phenolic resin evenly adheres to the surface of the ceramic particles, and then fill the mixed material in two molds with symmetrical hemispherical grooves, the balls of the hemispherical grooves The radius is 5 mm, and then the two molds are put together, and the mold is disassembled after the binder is solidified to obtain a spherical ceramic preform wi...

Embodiment 2

[0056] The preparation of embodiment 2 wear-resistant hammer head

[0057] Step 1: Pretreatment of Ceramic Particles

[0058] The surface of the zirconium corundum ceramic particles with a particle size of 1.0-2.0mm and 2.0-4.0mm is subjected to nickel-plating treatment, and the mass ratio of the zirconium corundum ceramic particles with a particle size of 1.0-2.0mm and 2.0-4.0mm is 5:5 . The process of nickel plating includes the processes of surface treatment and plating.

[0059] Step 2: Preparation of ceramic preform

[0060] Mix the phenolic resin and the above-mentioned dispersed ceramic particles evenly, so that the phenolic resin evenly adheres to the surface of the ceramic particles, and then fill the mixed material in two molds with symmetrical hemispherical grooves, the balls of the hemispherical grooves The radius is 5 mm, and then the two molds are put together, and the mold is disassembled after the binder is solidified to obtain a spherical ceramic preform wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com