Modified waterborne polyurethane as well as preparation method and application thereof

A water-based polyurethane modification technology, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems of low temperature resistance and poor tensile strength, and achieve low temperature resistance and tensile strength Improve the effect of good emulsion stability and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

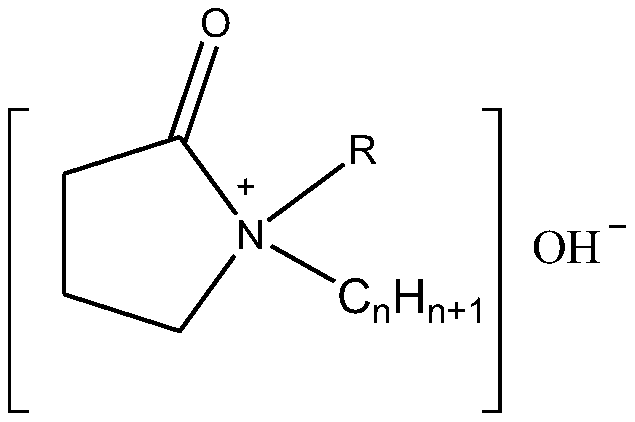

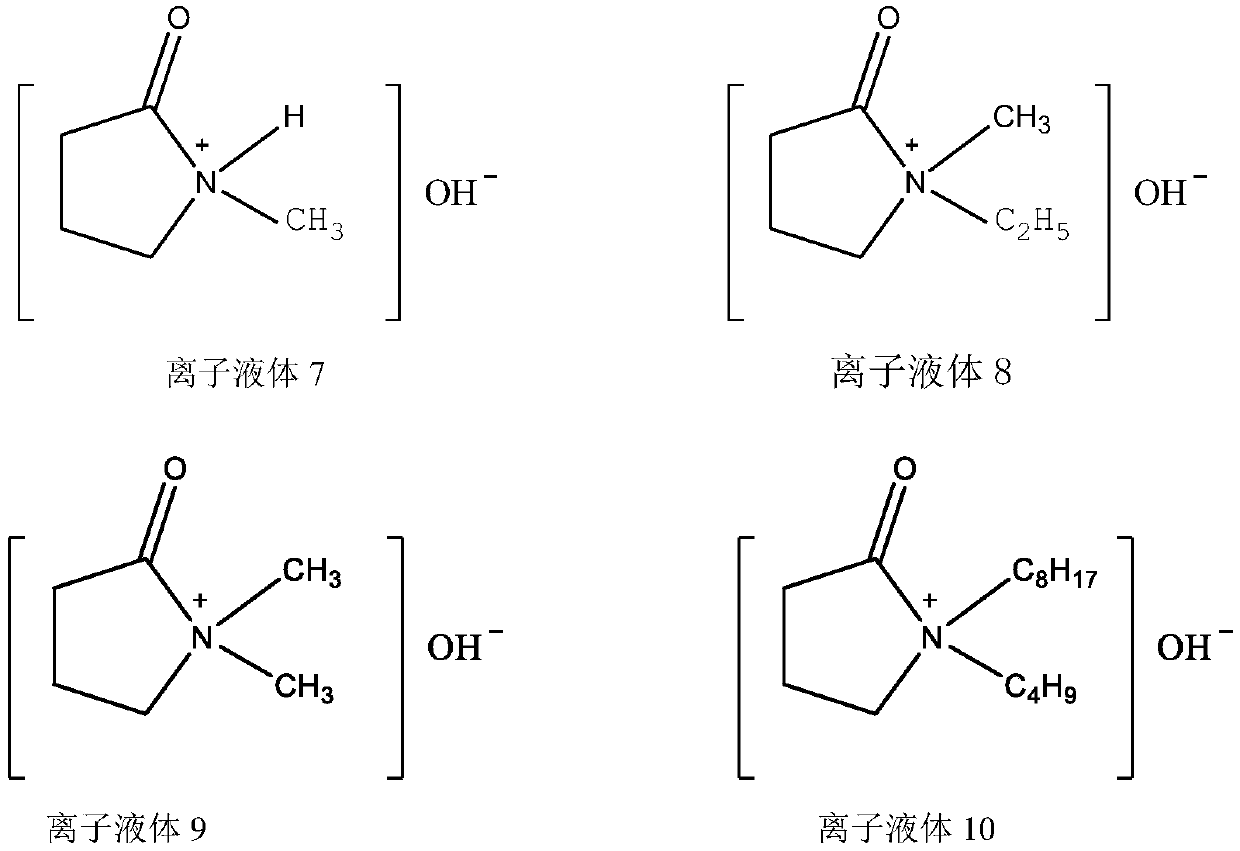

[0041] The second aspect of the present invention provides a kind of preparation method of modified waterborne polyurethane, comprises the following steps:

[0042] Step 1, after mixing (15-20) parts by weight of polyester polyol and (4-15) parts by weight of polyisocyanate, add (0.02-0.6) parts by weight of catalyst to the mixed solution, in an inert gas protective atmosphere Next, stir the reaction at 70-90°C for a period of time. Preferably, the weight ratio of polyester polyol to polyisocyanate is (1.5-4.5):1, such as 1.5:1, 2.5:1, 3.5:1, 4.5:1. The weight ratio of polyester polyol to catalyst can be (15-25):1, for example, it can be 15:1, 20:1, 25:1.

[0043] In this step, the polyester polyol and the polyisocyanate can be put into a four-necked flask equipped with a stirrer, a thermometer, and a condensing tube to react. The reaction can be carried out under nitrogen protection, and the rotating speed of the stirrer can be 50-200 rpm. min, the whole reaction can be car...

Embodiment 1

[0055] Add polyethylene adipate diol [PEA, M=2000] and toluene diisocyanate (TDI) into a four-necked flask equipped with a stirrer, a thermometer, and a condenser, {m[PEA]:m(TDI )=2.5:1}, in N 2 Under a protective atmosphere, add n-butyl titanate dropwise as a catalyst, {m[PEA]:m(n-butyl titanate)=25:1}, stir and react at 90°C for 2h; then add dimethylolpropane Add the acid (DMPA) slowly (within 1h) to the above solution, where {(m(DMPA):m[PEA]=1:15}, continue to stir the reaction mixture solution at 90°C for 0.5h; then caprolactam Add the basic ionic liquid (ionic liquid 1) to the above solution, where {(m(ionic liquid 1):m[PEA]=1:20}, continue to stir the mixed solution at 90°C for 2h; take a certain amount Add triethylamine to the above solution to adjust pH=7±0.5 to obtain a prepolymer; disperse the obtained prepolymer in deionized water to obtain a water-based polyurethane emulsion WPU, control the amount of deionized water to ensure that the solid content is greater tha...

Embodiment 2

[0061] Add polyethylene adipate diol [PEA, M=2000] and toluene diisocyanate (TDI) into a four-necked flask equipped with a stirrer, a thermometer, and a condenser, {m[PEA]:m(TDI )=4.5:1}, in N 2 Under a protective atmosphere, add n-butyl titanate dropwise as a catalyst, {m[PEA]:m(n-butyl titanate)=20:1}, stir and react at 70°C for 1h; then add dimethylolpropane Add the acid (DMPA) slowly (within 1h) to the above solution, where {(m(DMPA):m[PEA]=1:20}, continue to stir the reaction mixture solution at 70°C for 0.5h; then caprolactam Add the basic ionic liquid (ionic liquid 2) into the above solution, where {(m(ionic liquid 1):m[PEA]=1:15}, continue to stir the mixed solution at 70°C for 2h; take a certain amount Add triethylamine to the above solution to adjust pH=7±0.5 to obtain a prepolymer; the obtained prepolymer is dispersed in deionized water to obtain a water-based polyurethane emulsion WPU, and the amount of deionized water is controlled to ensure that the solid conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com