Material produced by taking municipal white garbage as raw material and replacing various plate raw materials

A technology of white garbage and raw materials, which is applied in the field of materials to replace various plate materials, can solve the problems of white garbage pollution, etc., and achieve the effect of wide market, low cost and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

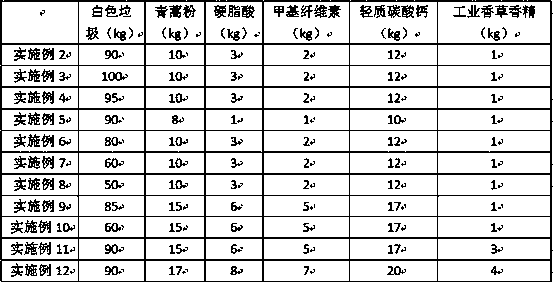

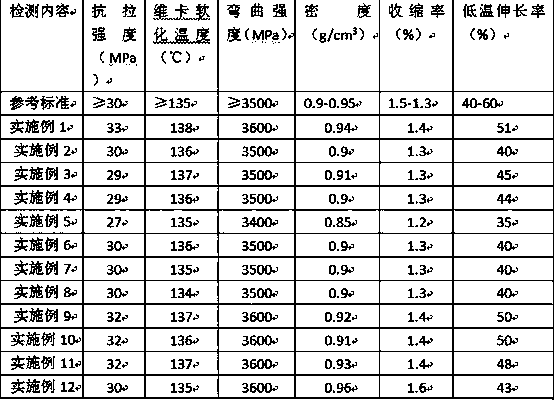

Examples

Embodiment 1

[0032] (1) Cleaning and drying: Weigh 70kg of white garbage and wash it with clean water until there is no residue on the surface of the white garbage, then wash it again with clean water, add an appropriate amount of 84 disinfectant to the water, soak for half an hour, and wash the white garbage with clean water. Rinse and dry with a dryer;

[0033] (2) Mixing: Weigh 10kg of Artemisia annua powder, 3kg of stearic acid, 2kg of methylcellulose, 12kg of light calcium carbonate and 1kg of vanilla essence for industrial use, mix with white garbage, keep stirring at 30°C until all raw materials are evenly mixed ;

[0034] (3) Pulverization: put the mixture obtained in step 2 into a ball mill for pulverization to obtain granules;

[0035] (4) Grinding: put the particles obtained in step 3 into a grinder, and grind the particles to 800 mesh powder;

[0036] (5) Packing: Put the above powder materials into the filling machine, fill and pack according to the requirements.

[0037] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com