Automatic water-separating and dust-settling device for blast furnace gas

A blast furnace gas and dust reduction device technology, which is applied in the direction of gas dust removal, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of potential safety hazards, easy flameout, low calorific value, etc., to prolong the service life, the device structure is simple, Effect of improving gas quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

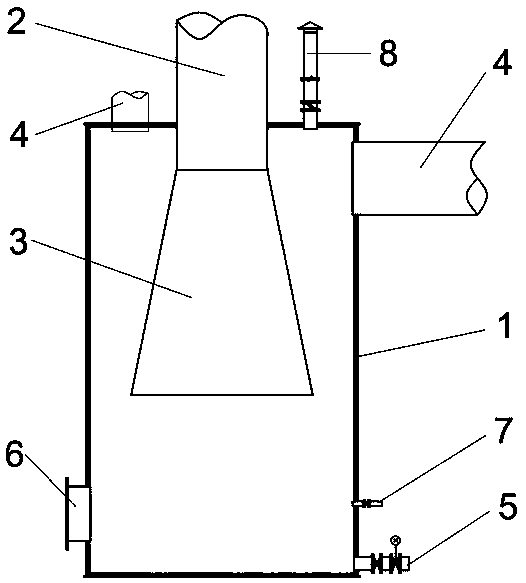

[0022] Using the present invention, nitrogen or steam is used to purge the interior of the equipment through the nitrogen or steam purge inlet 7, and the air in the pipe is discharged by the release pipe, and the blast furnace gas is transported through the gas inlet 2 into the trumpet tube 3 provided in the shell 1, and the blast furnace gas After entering the trumpet tube 3, it will decelerate and diffuse immediately, the kinetic energy will decrease, the dew point will drop rapidly, and a large amount of mechanical water will be precipitated. The mechanical water will fall to the lower part of the shell 1 by gravity. At the bottom of the cylinder, the gas passes through the gas outlet 4 above the cylinder, and is transported to other units through the gas pipeline as fuel, and the solenoid valve of the drainage and sewage valve group 5 is opened to discharge the water and dust precipitated at the bottom of the cylinder.

Embodiment 2

[0024] When maintaining and overhauling the equipment, use nitrogen or steam to purge the inlet 7 to purge the inside of the equipment, use the release pipe to discharge the gas in the pipe, prevent the formation of explosive mixed gas in the pipe, and open the manhole 6, Equipment personnel perform maintenance and overhaul.

[0025] In the present invention, the blast furnace gas containing dust and moisture enters the horn tube 3 from the gas inlet 2 through the horn tube 3, and immediately decelerates and diffuses, the kinetic energy decreases, the dew point drops rapidly, and a large amount of mechanical water is precipitated, and the mechanical water falls to the lower part of the cylinder body by gravity. At the same time as the moisture is precipitated, the dust in the gas and the mechanical water fall to the bottom of the cylinder under the action of gravity, and then are discharged from the drainage and sewage valve group 5. According to the actual measurement during t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com