A method of automatic measurement and construction of piles formed by long auger drilling rigs

A long auger, automatic measurement technology, applied in the directions of rotary drilling rigs, drilling equipment and methods, measurement, etc., can solve the problems of difficult construction coordination, affecting the quality of piles, low labor efficiency, etc. The effect of avoiding insufficient or overlong empty pile heads and ensuring the quality of piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

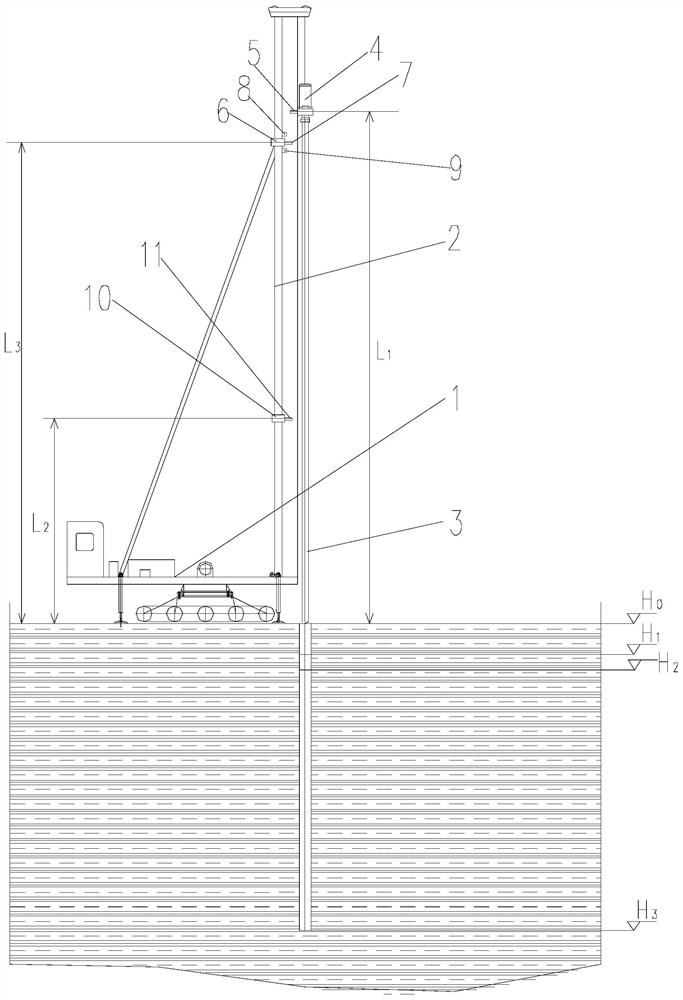

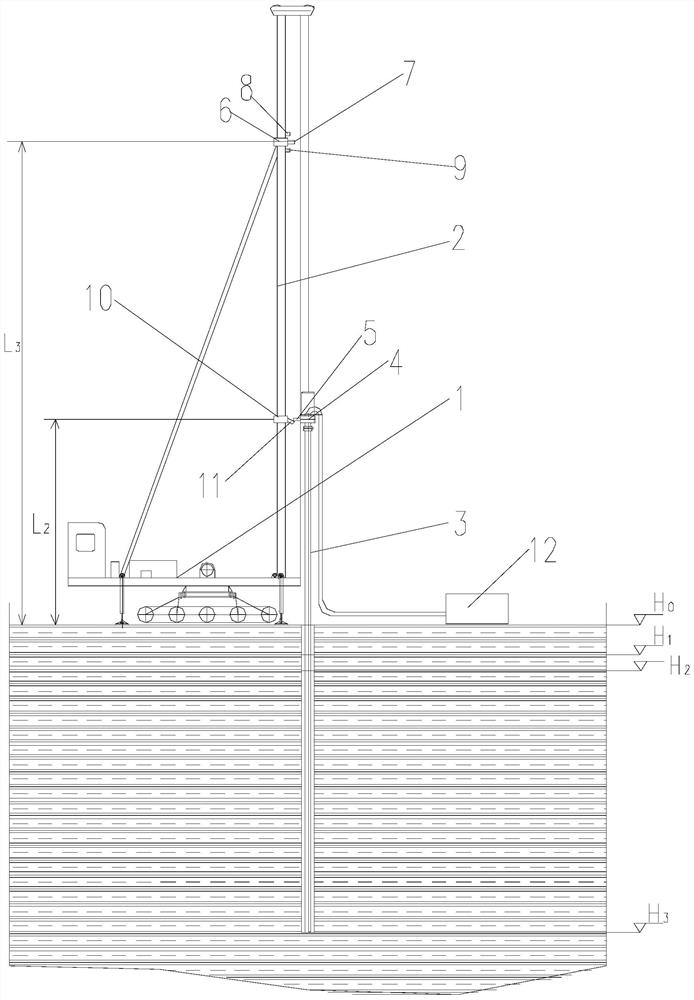

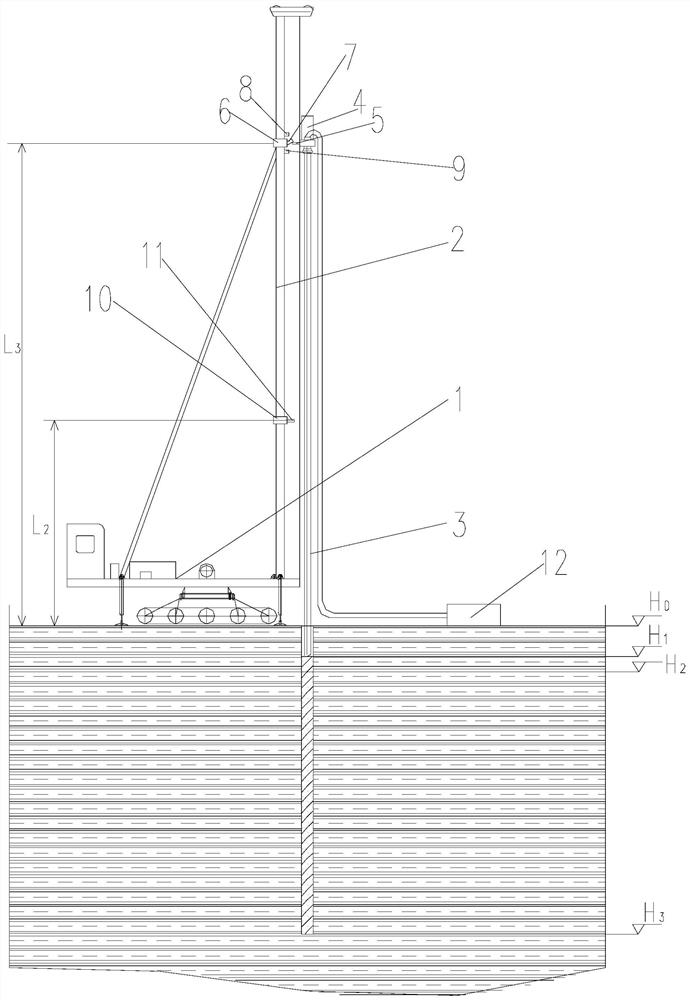

[0045] like Figure 1 to Figure 6 Shown, a kind of long auger drilling rig of the present invention piles automatic measurement construction method, comprises the following steps:

[0046] Step 1. Level the construction site and determine the pile position: clear the obstacles in the construction area, level the construction site, keep the construction work surface at the same elevation, measure and place the pile position according to the site level control point, coordinate control point and construction drawing, and move The long auger rig 1 arrives at the designated position, and the long auger rod 3 is vertically aligned with the pile position;

[0047] Step 2, install the trigger rod: install the trigger rod 5 in the direction that the drill head 4 of the long auger drill rod 3 faces the direction of the long auger drill 1;

[0048] Step 3. According to the formula L 2 = L 1 -(H 0 -H 3 ), estimate the installation elevation of the drill rod limiter module 10 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com