Multi-channel in-situ detection device and detection method for subsurface defects of optical components

A sub-surface defect and optical element technology, applied in the field of optical elements, can solve the problems that the measurement results are greatly affected by scattering, it is difficult to accurately locate and reset the same micro-nano defect, and the detection sensitivity is low, so as to achieve compact structure and avoid influence , detect the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

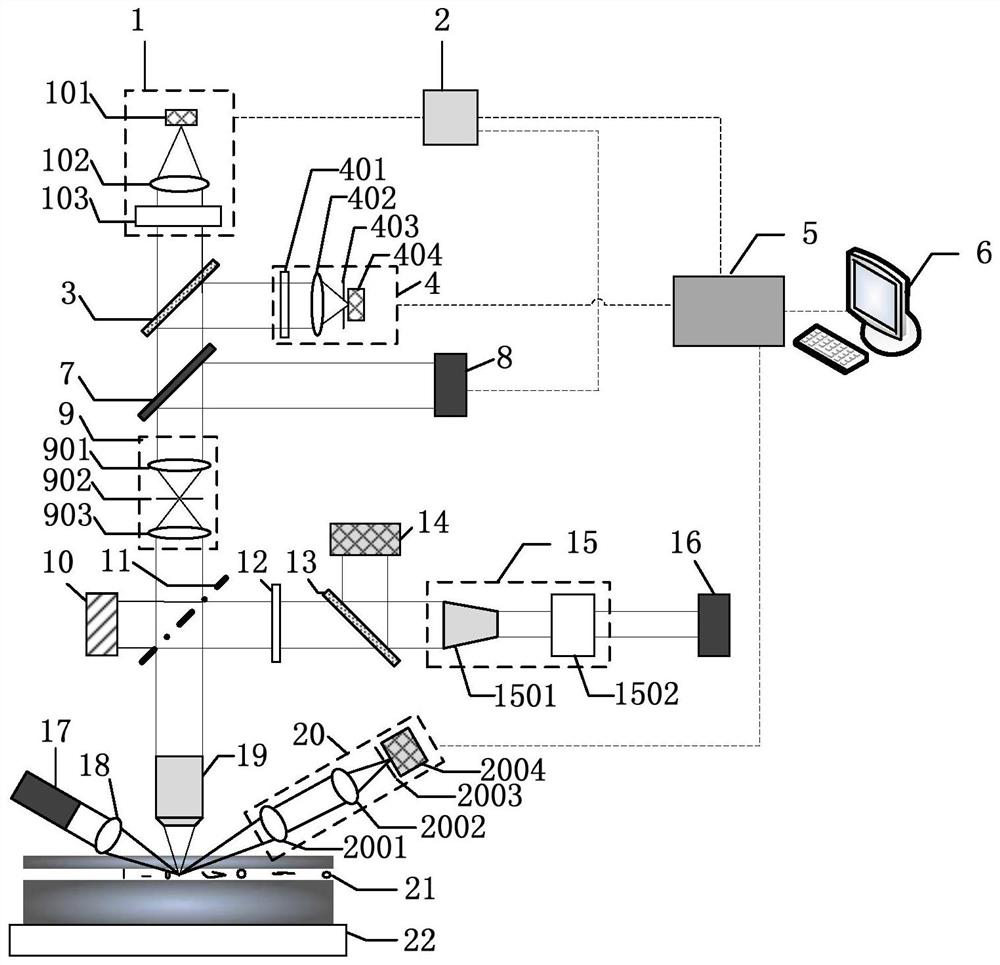

[0067] The short pulse laser light source 8 provides a picosecond high-frequency laser pulse, a wavelength of 375 nm, is used to excite optical element defects to generate photorefluorescence, and use it as an excitation signal access time-dependent single optical sub-count module 2; The dichroic mirror 7 is a long-in-chi-chromatic frame, which is high than the laser light having a wavelength of less than 375 nm, which is higher than the laser light of 375 nm, and the wavelength of the laser light source and the fluorescence wavelength is separated.

[0068] The confocal module 9 includes a lens 901, aperture 902, a lens 902, which is a co-focused detecting system 4, a microscopic amplification system 19, and the optical element 21 sub-surface constitutes a confocal system for achieving sub-surface defective Geometric high-resolution measurement, the small hole 902 diameter is 10 μm, the transverse resolution of the confocal detection system xy The wavelength of the excitation las...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com