A kind of electrochromic glass based on molybdenum trioxide film, its preparation method and application

An electrochromic glass, molybdenum trioxide technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of low blocking efficiency, full solar spectrum band blocking, technical obstacles, etc., and achieve uniform and dense surface and thin film thickness. Adjustable, transmittance adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a method of preparing an electrochromic glass based on a molybdenum dioxide film, including:

[0032] A) Preparation MOO 3 film;

[0033] Preparation of electrolyte: Heating electrolyte is dissolved in a solvent to obtain a liquid electrolyte;

[0034] B) Apply the liquid electrolyte to MOO 3 The surface of the film is applied to the liquid electrolyte in the surface of the film, and the encapsulates to be MOO. 3 / Liquid electrolyte / ITO sandwich structure;

[0035] C) MOO of the sandwich structure 3 Connect the working electrode, the ITO connection to the electrode and the reference electrode to obtain electrochromic glass based on the molybdenum oxide film.

[0036] The preparation method of electrochromic glass based on the molybdenum oxide film provided by the present invention is first prepared by MOO 3 film.

[0037] Preparation of MOO of the present invention 3 The film is preferably specifically:

[0038] As the substrate as the ITO ...

Embodiment 1

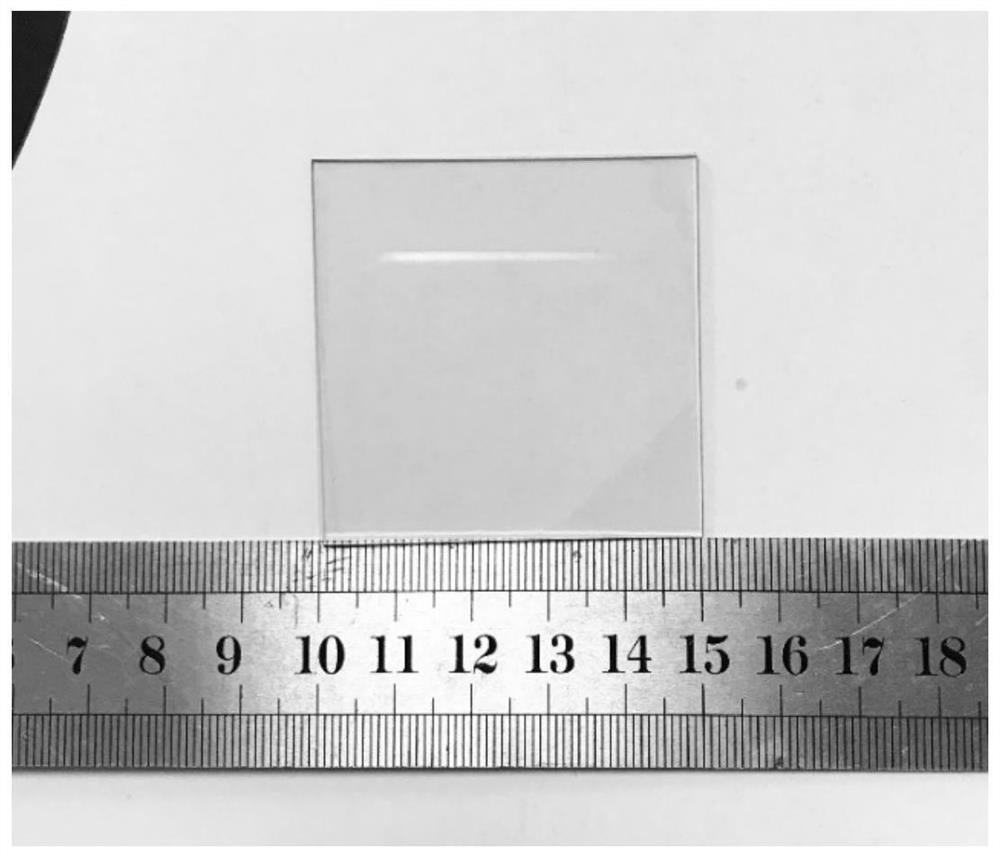

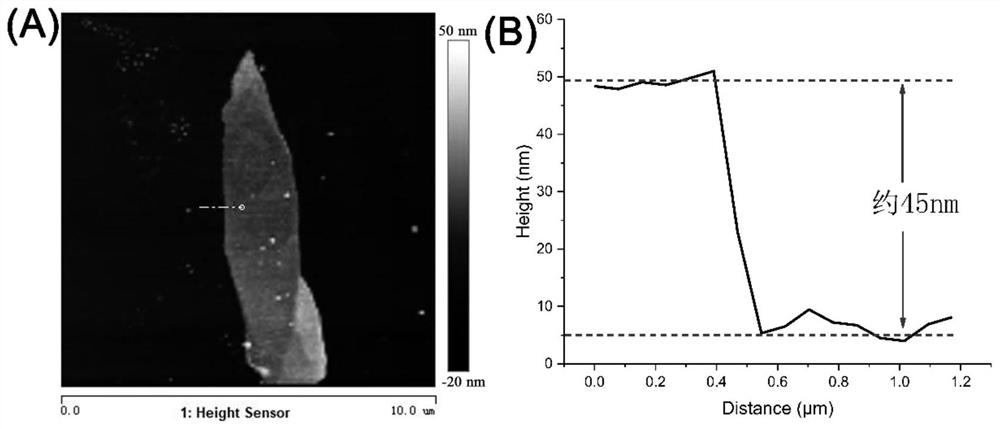

[0065] Preparation MOO 3 Film: Use the commercial ITO glass substrate to cut it into a size of 5 cm × 5 cm, using a magnetron sputtering device, the chamber is vacuum is 4.5 × 10 -7 Torr, cavity temperature is 298K, RF power source power 200W, AR gas flow 30sccm; O 2 Gas flow 3sccm; coating, cavity vacuum 3mtorr, growth time is 1200s, growing a thickness of MOO 3 film.

[0066] 1.2G liclo 4 · 3h 2 O, in 5 ml of propylene carbonate (PC), after heating the solvent to 60 ° C, it is placed in an ultrasound for 2 hours to obtain a liquid electrolyte.

[0067] Wipe the liquid-like electrolyte evenly in MOO 3 The surface of the film, the other ITO glass conductive surface is close to the liquid electrolyte, control ITO glass and MOO 3 The distance between the surface of the film is 1 mm, then use a package glue package to make MOO 3 / Liquid electrolyte / ITO sandwich structure. In MOO 3 The film and ITO port connecting electrodes are connected to the DC voltage source and the reference ...

Embodiment 2

[0072] Preparation MOO 3 Film: Use the commercial ITO glass substrate to cut it into a size of 6 cm × 6cm, using magnetron sputtering equipment, cavity bottom vacuum is 4 × 10 -7 Torr, cavity temperature is 290K, radio frequency power source power is 180W, AR gas flow 25sccm; O 2 Air flow 2.8sccm; coating, cavity vacuum 2.5mtorr, growth time is 1000S, growing a thickness of MOO 3 film.

[0073] 2.4G liclo 4 · 3h 2 O, dissolved in 10 ml of vinyl carbonate (EC), after heating the solvent to 70 ° C, it was placed in an ultrasound for 3 hours to obtain a liquid electrolyte.

[0074] Wipe the liquid-like electrolyte evenly in MOO 3 The surface of the film, the other ITO glass conductive surface is close to the liquid electrolyte, control ITO glass and MOO 3 The distance from the surface of the film is 1.2mm, then use a package glue package to make MOO 3 / Liquid electrolyte / ITO sandwich structure. In MOO 3 The film and ITO port connecting electrodes are connected to the DC voltage so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com