Device for indirect catalytic oxidation of diesel vehicle tail gas pollutants by air micro-nano bubbles

A technology of micro-nano bubbles and catalytic oxidation, which is applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve the problems of gas volume limitation, etc., and achieve increased gas-liquid mass transfer efficiency, low energy consumption, and improved The effect of throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

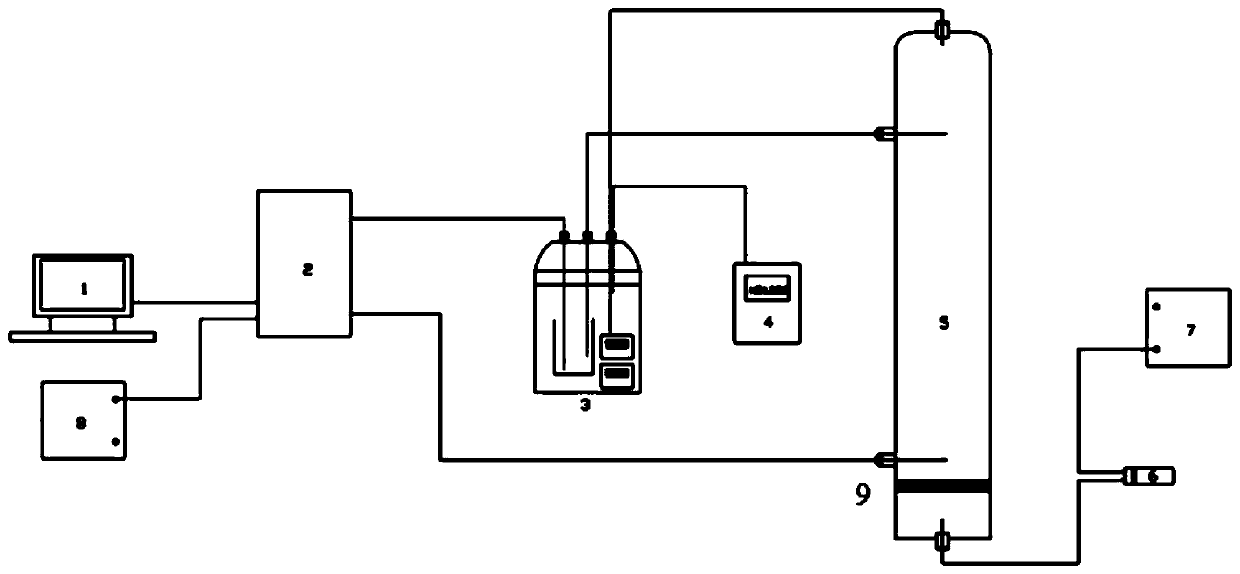

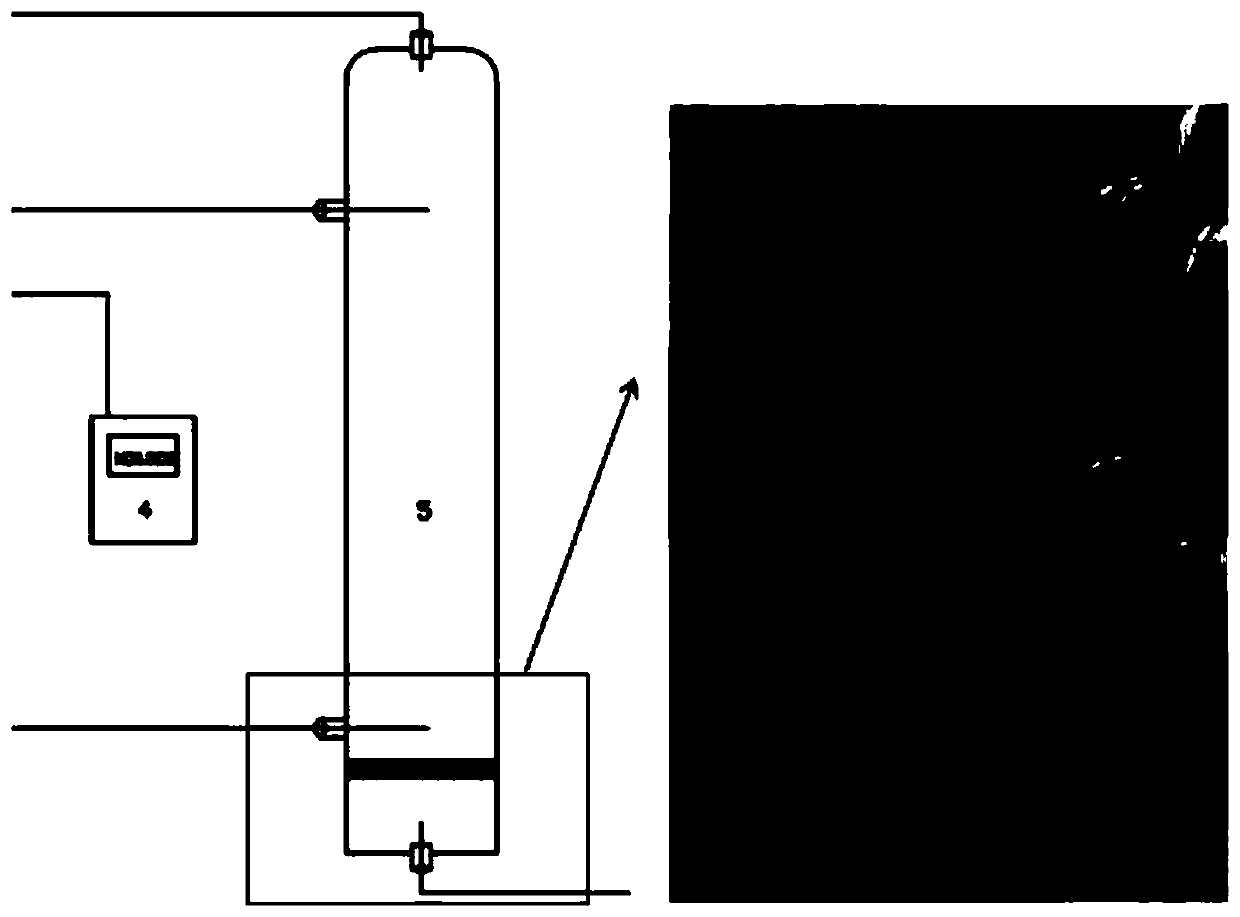

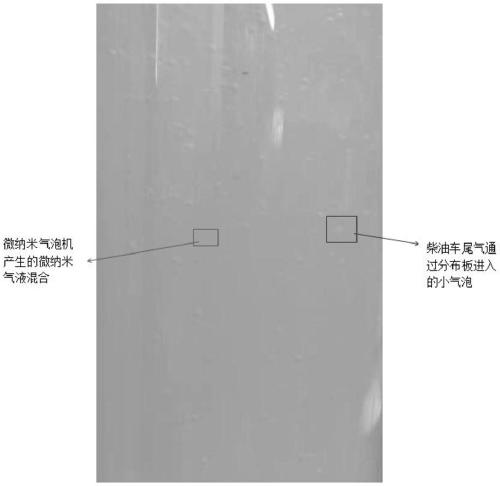

[0049] This embodiment provides a device for indirect catalytic oxidation of various gases in diesel vehicle exhaust by micro-nano bubbles, such as figure 1 As shown, the device includes: an air collection bag 8 and a computer 1 are respectively connected to the micro-nano bubble generator 2, the upper part of the micro-nano bubble generator 2 is connected to the upper part of the reaction tower 5 through a glass tank 3, and the lower part of the micro-nano bubble generator 2 It is connected to the lower part of the reaction tower 5, the top of the reaction tower 5 is connected to the glass tank 3, the glass tank 3 is connected to the flue gas analyzer 4, and the bottom of the reaction tower 5 is connected to the diesel vehicle exhaust gas collection bag 7 through the gas pump 6, wherein the reaction tower The distribution plate 9 is arranged at the bottom of the 5, the connection between the bottom of the micro-nano bubble generator 2 and the bottom of the reaction tower 5 is...

Embodiment 2

[0051] For example, to adjust the salinity factor, use distilled water to prepare absorption solutions with NaCl concentrations of 0.1g / L, 0.3g / L, 0.5g / L, 0.7g / L, and 0.9g / L to explore the system’s response to NO and SO 2 removal efficiency.

[0052] S1: Use diesel engine, collect exhaust gas, measure its NO and SO 2 The concentrations are 200ppm and 300ppm respectively.

[0053] S2: Connect the device in Example 1, use the micro-nano bubble machine, the rated water flow rate of the micro-nano bubble generator is 300mL / min, the rated air intake volume is 50mL / min, and the gas-liquid mixture of air and absorption liquid is 350mL / min. The min micro-nano bubble liquid enters the reaction column from 10cm above the distribution plate 9 below the reaction tower 5, and the reaction column is filled with absorption liquid and circulates with the liquid in the micro-nano bubble instrument, and the tail gas is pumped through the gas pump 6 at an air intake of 1.1L / min. Enter below th...

Embodiment 3

[0057] S1: Urea promotes NO and SO 2 The treatment efficiency increases, and distilled water is used to configure the absorption solution with 2%, 4%, 6%, and 8% concentration of urea.

[0058] S2: Use diesel engine, collect exhaust gas, measure its NO and SO 2 The concentrations are 200ppm and 300ppm respectively.

[0059] S3: Connect the device in Example 1, use the micro-nano bubble generator, the rated water flow rate of the micro-nano bubble generator is 300mL / min, the rated air intake volume is 50mL / min, inject 350mL / min, the air and the absorption liquid generate gas The liquid is mixed into a micro-nano bubble liquid, from the bottom of the reaction tower 5 to 10cm above the distribution plate 9, the reaction column is filled with the absorption liquid and the liquid in the micro-nano bubble instrument circulates, and the tail gas is pumped into the bottom of the distribution plate 9 through the gas pump 6 at 1.1L / min , the generated bubbles are also mixed with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com