Abrasive Flow Polishing System Enhanced by Hydrodynamic Cavitation on Inner Cylindrical Surface

A technology of hydraulic cavitation and abrasive flow, which is used in grinding/polishing equipment, surface polishing machine tools, grinding machines, etc., can solve the problems of difficult to adapt to the ultra-precision polishing of the inner cylindrical surface of tubular parts, and achieves improved utilization efficiency, The effect of reducing sewage discharge and improving circulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing:

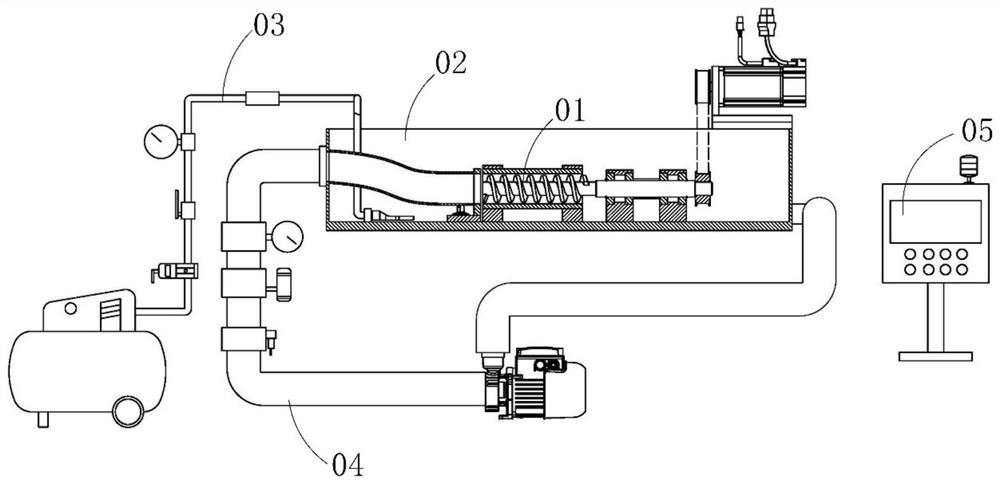

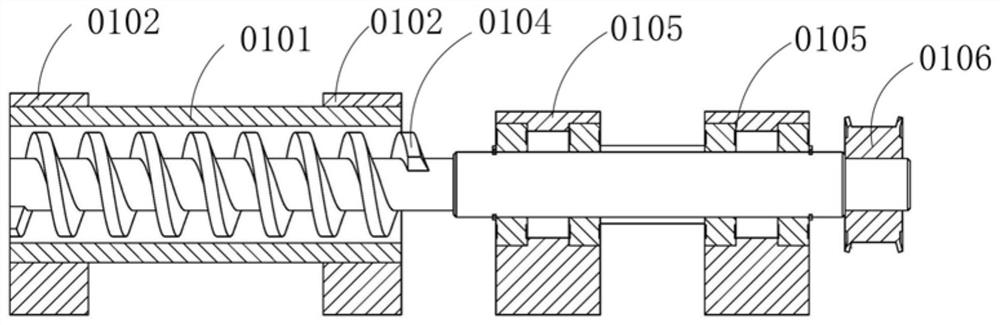

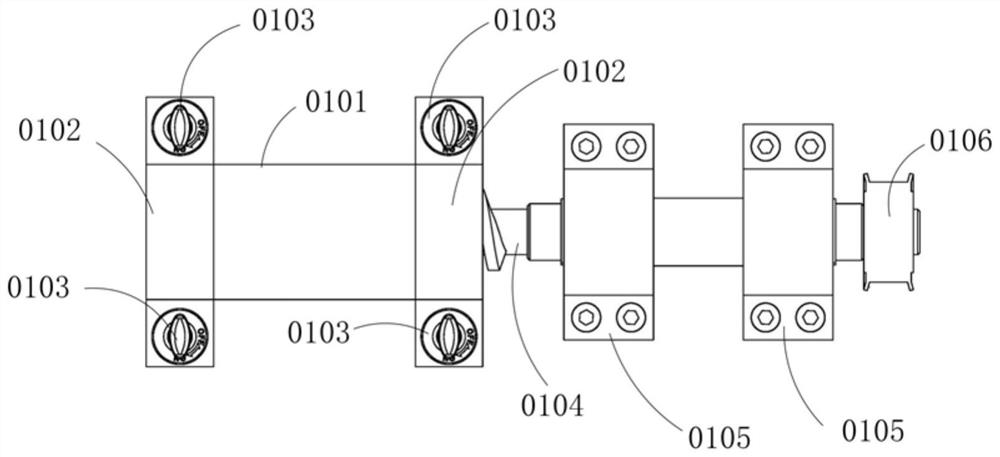

[0039] Such as Figure 1~10 As shown, an inner cylindrical surface hydraulic cavitation enhanced abrasive flow polishing system is used to process the inner cylindrical surface of the workpiece 0101 with an inner cylindrical surface. It is characterized in that it includes a polishing module 01, a base module 02. High-pressure gas injection module 03, abrasive flow circulation module 04 and control system 05, the polishing module 01 is installed in the abrasive flow processing pool 0201 on the base module 02, the high-pressure gas injection module 03 The gas outlet is located at the bottom of the abrasive flow processing pool 0201, and the high-pressure gas generated by the high-pressure gas injection module 03 is injected into the abrasive flow processing pool 0201 through the gas outlet to blow the abrasive particles deposited on the bottom of the abrasive flow processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com