PTFE multi-layer extrusion pipe and preparation method thereof

A multi-layer extrusion, PTFE technology, applied in chemical instruments and methods, layered products, tubular articles, etc., can solve the problem of not being able to obtain a two-layer structure with inner black and outer white, achieve a good competitive advantage, reduce manufacturing Cost, effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

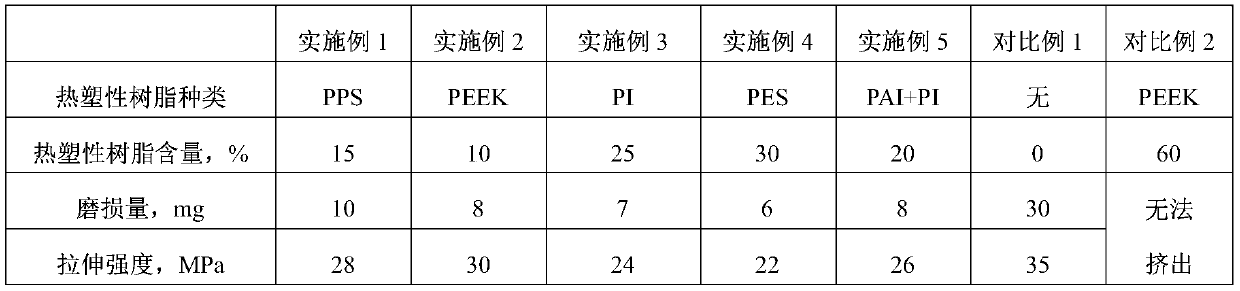

Examples

Embodiment 1

[0035] A kind of preparation method of PTFE multi-layer extruded pipe, comprises steps as follows:

[0036] (1) Mixing and preforming of the inner layer material: Mix 15wt% PPS resin and 85wt% PTFE dispersion resin DF-2041 (Dongyue Group) after sieving to obtain a modified PTFE dispersion resin, add Mobil The addition of isopar G additive oil is 17wt% of the modified PTFE dispersion resin, and then placed on the mixing equipment and mixed at a speed of 30r / min for 30min, and the mixed inner layer material was placed in an environment of 25°C for 24h , using a cylinder with an outer diameter of 30mm for preforming, the preforming pressure is 2.0MPa, and the holding time is 20min to obtain the inner layer material ring body;

[0037] (2) Mixing and preforming of the outer layer material: add isopar G to the sieved PTFE dispersion resin DF-2041 (Dongyue Group), the amount of isopar G added is 17wt of the sieved PTFE dispersion resin %, put it on the mixing equipment and mix it a...

Embodiment 2

[0041] A kind of preparation method of PTFE multi-layer extruded pipe, comprises steps as follows:

[0042](1) Mixing and preforming of the inner layer material: Mix 10wt% PEEK resin and sieved 90wt% PTFE dispersion resin DF-2041 (Dongyue Group) evenly to obtain a modified PTFE dispersion resin, add Mobil's The addition of isopar G additive oil is 19wt% of the modified PTFE dispersion resin, and then placed on the mixing equipment and mixed at a speed of 30r / min for 30min, and the mixed inner layer material was placed in an environment of 25°C for 28h , using a cylinder with an outer diameter of 35mm for preforming, the preforming pressure is 2.5MPa, and the holding time is 30min to obtain the inner layer material ring blank;

[0043] (2) Mixing and preforming of the outer layer material: add isopar G to the sieved PTFE dispersion resin DF-2041 (Dongyue Group), the amount of isopar G added is 19wt of the sieved PTFE dispersion resin %, put it on the mixing equipment and mix i...

Embodiment 3

[0047] A kind of preparation method of PTFE multi-layer extruded pipe, comprises steps as follows:

[0048] (1) Mixing and preforming of the inner layer material: Mix 25wt% PI resin and 75wt% PTFE dispersion resin DF-2041 (Dongyue Group) after sieving to obtain a modified PTFE dispersion resin, add Mobil The addition of isopar G additive oil is 20wt% of the modified PTFE dispersion resin, then placed on the mixing equipment and mixed at a speed of 30r / min for 30min, and the mixed inner layer material was placed in an environment of 30°C for 24h , using a cylinder with an outer diameter of 50mm for preforming, the preforming pressure is 3.0MPa, and the pressure holding time is 35min to obtain the inner layer material ring body;

[0049] (2) Mixing and preforming of the outer layer material: add isopar G to the sieved PTFE dispersion resin DF-2041 (Dongyue Group), the amount of isopar G added is 20wt of the sieved PTFE dispersion resin %, put it on the mixing equipment and mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com