Generator rotor shaft end face marking system and working method thereof

A generator rotor and marking system technology, applied to typewriters, computer parts, and collaborative work devices, etc., can solve the problems that cannot meet the needs of mass production, automation efficiency, information management, security and data traceability, and automation. The low level of information management and easy to make mistakes or omissions on the end face of the rotor shaft can achieve the effects of ensuring traceability, reducing manual intervention, and improving error correction and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

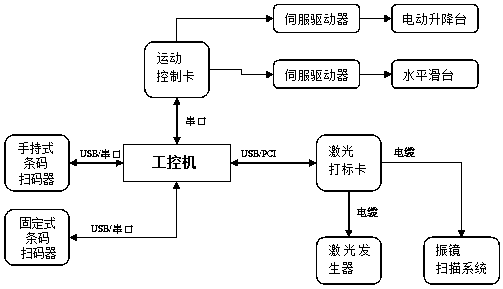

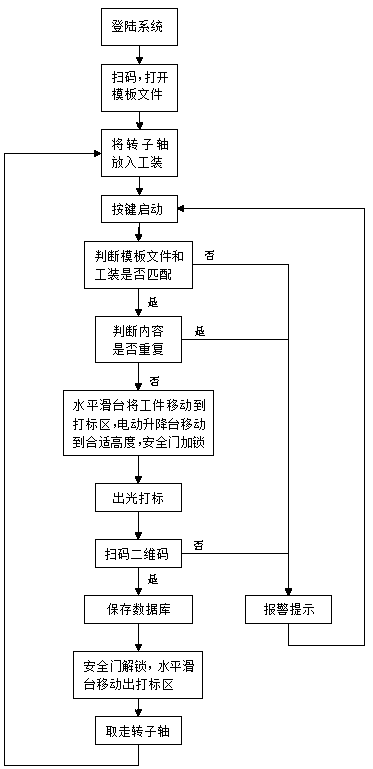

[0031] Such as figure 1 As shown, this embodiment provides a generator rotor shaft end face marking system, including an industrial computer, a barcode scanner, a motion control card, a servo driver, an electric lifting platform, a horizontal sliding platform, a laser marking card, a laser generator, Galvanometer scanning system, the industrial computer is connected to the barcode scanner through the serial port / USB, the industrial computer is connected to the motion control card through the serial port, the motion control card is connected to the servo driver, and the servo driver is connected to the electric lifting platform and the horizontal slide through cables The industrial computer is connected to the laser marking card through the PCI / USB interface, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com