Copper mural manufacturing method

A production method and mural technology, applied in special decorative structures, decorative arts, etc., can solve the problems of not being able to process pictures on both sides at the same time, high operator professionalism requirements, low production efficiency, etc., and achieve soft pictures and low professionalism requirements. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for making copper murals includes the following steps:

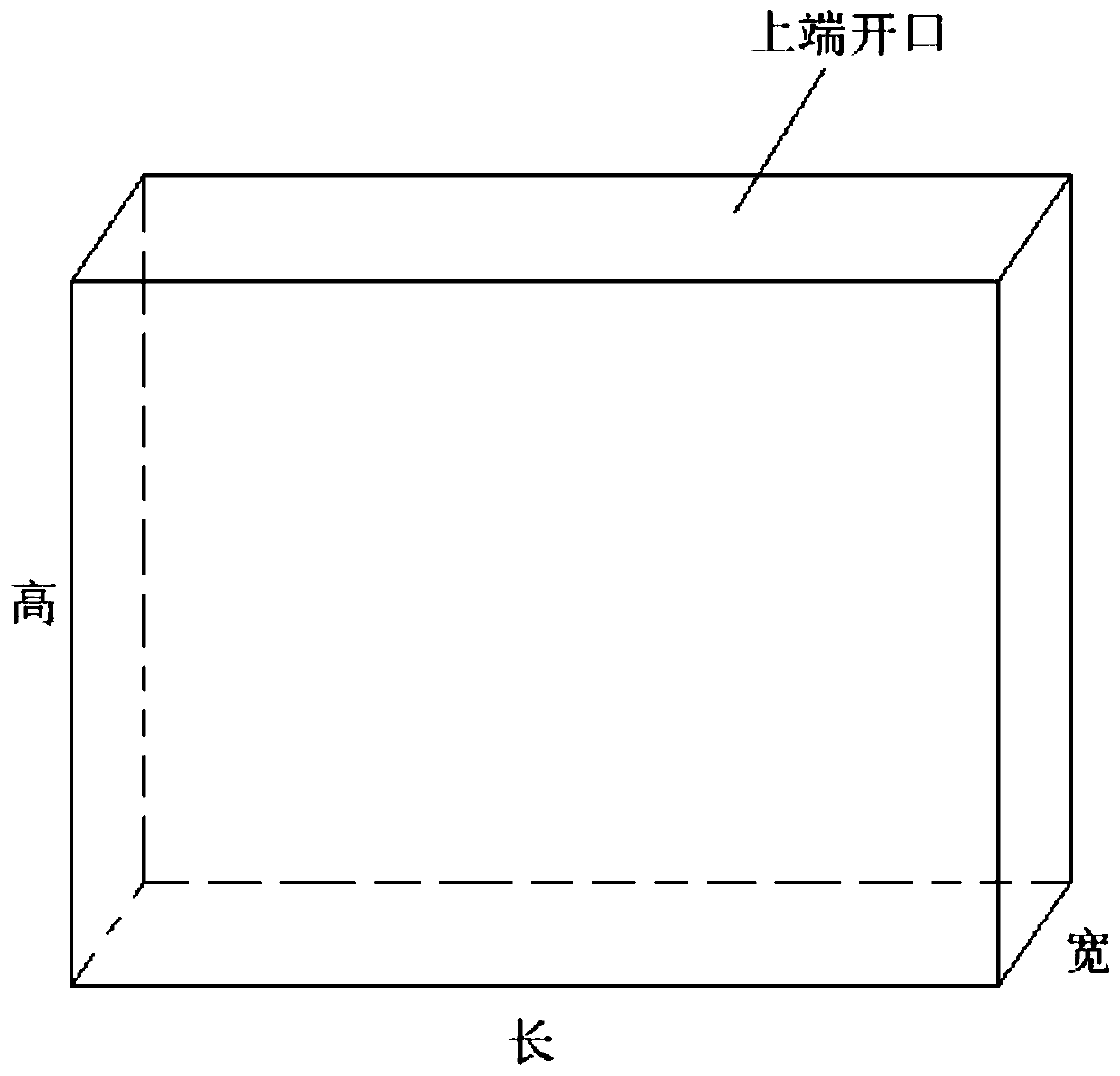

[0032] Step 1: Use a wooden board with a thickness of 10 mm to make a rectangular wooden box with an open upper end as a wooden mold for casting; the cavity size of the wooden mold is: length 1000 mm, width 5 mm, and height 500 mm.

[0033] Step 2: Heat and melt a mixture of copper scraps (brass scraps), low-melting metal tin, aluminum, and flux boron to obtain a casting solution. The amount of tin is 1% of the weight of copper scraps, and the amount of aluminum is copper scraps 0.5% by weight, the amount of borax is 0.2% by weight of copper scraps.

[0034] Step 3: Immerse the wooden mold in water for 1 minute, then take out the wooden mold and pour out the water in the wooden mold.

[0035] Step 4: Pour the casting liquid slowly from the opening at the upper end of the wooden mold into the cavity of the wooden mold. The casting liquid is poured into the cavity of the wooden mold at one time, and the copper mate...

Embodiment 2

[0039] A method for making copper murals includes the following steps:

[0040] Step 1: Using a wooden board with a thickness of 15mm to make a rectangular wooden box with an open upper end as a wooden mold for casting; the cavity size of the wooden mold is: length 2000mm, width 15mm, and height 1200mm.

[0041] Step 2: Heat and melt a mixture of copper scraps (brass scraps), low-melting metal tin, aluminum, and flux boron to obtain a casting liquid. The amount of tin is 2% of the weight of copper scraps, and the amount of aluminum is copper scraps 1.5% by weight, and borax is 0.5% by weight of copper scraps.

[0042] Step 3: Immerse the wooden mold in water for 3 minutes, then take out the wooden mold and pour out the accumulated water in the wooden mold.

[0043] Step 4: Pour the casting liquid slowly from the upper opening of the wooden mold into the cavity of the wooden mold. The casting liquid is poured into the cavity of the wooden mold three times, and the copper material is po...

Embodiment 3

[0047] A method for making copper murals includes the following steps:

[0048] Step 1: Use a board with a thickness of 12 mm to make a rectangular wooden box with an open upper end as a wooden mold for casting; the cavity size of the wooden mold is: length 1900 mm, width 12 mm, and height 1000 mm.

[0049] Step 2: Heat and melt a mixture of copper scraps (brass scraps), low-melting metal tin, aluminum, and flux boron to obtain a casting liquid. The amount of tin is 1.5% of the weight of copper scraps, and the amount of aluminum is copper scraps 1% by weight, borax dosage is 0.3% by weight of copper scraps.

[0050] Step 3: Immerse the wooden mold in water for 2 minutes, then take out the wooden mold and pour out the accumulated water in the wooden mold.

[0051] Step 4: Pour the casting liquid slowly from the upper opening of the wooden mold into the cavity of the wooden mold. The casting liquid is poured into the cavity of the wooden mold three times, and the copper material is pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com