Degradable civil brush wire and production method thereof

A civilian, weight-ratio technology, applied in the field of brushes, can solve problems such as unrealizable, unattainable, and poor water absorption, and achieve the effect of facilitating the use of brushes, ensuring normal use, and improving water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

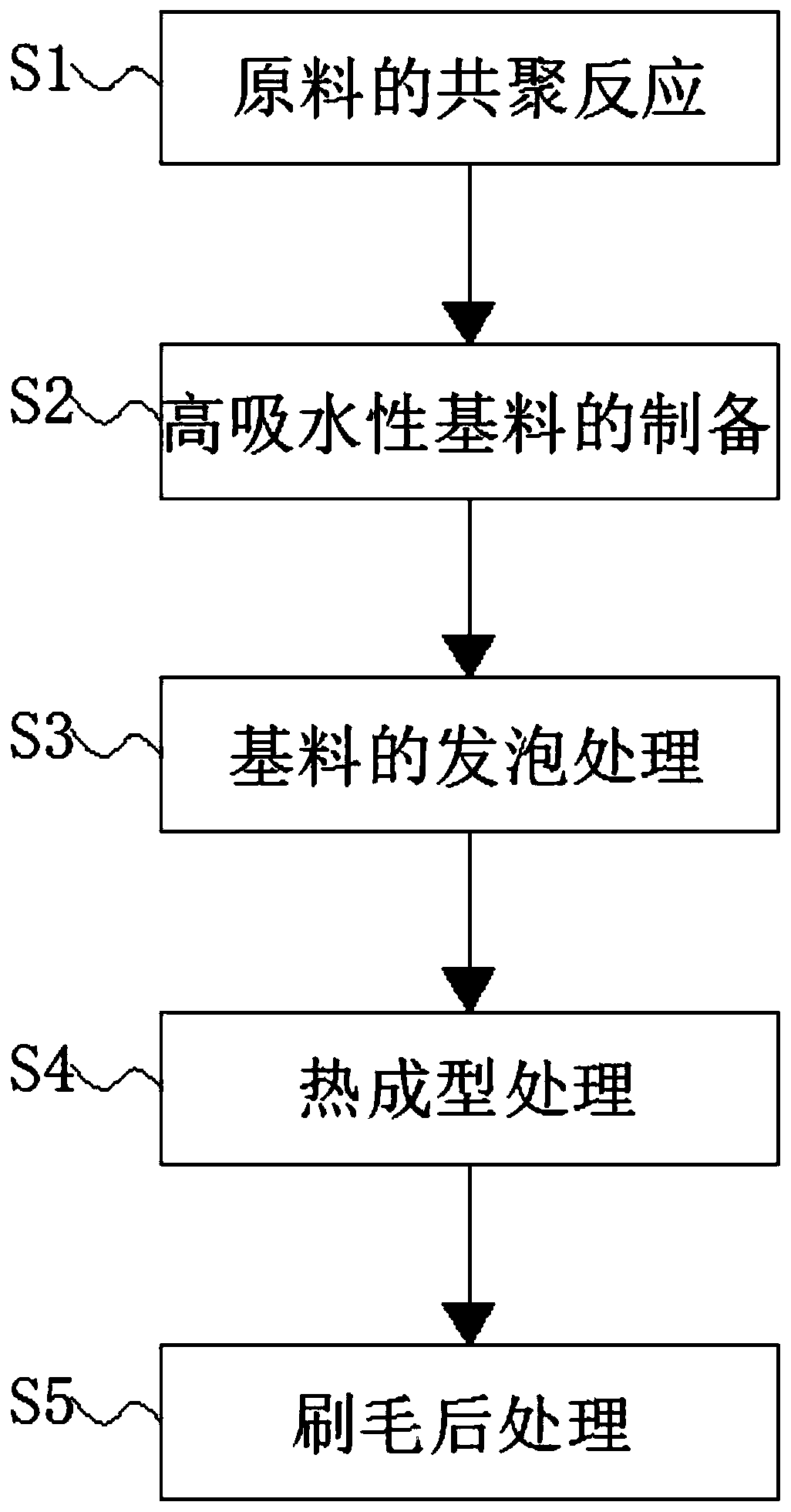

Image

Examples

Embodiment 1

[0030] S1. Copolymerization of raw materials: Firstly, select 35 parts of purified starch and 25 parts of carboxymethyl cellulose in corresponding weight ratios and add them to a hot melting furnace, add deionized water, and heat at 105°C for 5 minutes to make starch and The cellulose is mixed and becomes a paste, then the furnace temperature is lowered to 85°C, and then 7 parts of acrylic acid, 2 parts of initiator and 2 parts of stabilizer are sequentially added to the melting furnace in corresponding weight proportions, and the stirring equipment is used at a speed of 450r Under the condition of / min, stirring reaction 35min, thereby obtain reaction mass, initiator is the composition of ammonium persulfate and ammonium cerium nitrate, and stabilizer is polyethylene oxide;

[0031] S2. Preparation of super-absorbent base material: put the super-absorbent base material obtained in step S1, 4 parts of optical cable powder and 2 parts of cross-linking agent into the mixing and s...

Embodiment 2

[0036] S1. Copolymerization of raw materials: Firstly, select 30 parts of purified starch and 30 parts of carboxymethyl cellulose in corresponding weight ratios and add them to a hot melting furnace, add deionized water, and heat at 100°C for 3 minutes to make starch and The cellulose is mixed and becomes a paste, then the furnace temperature is lowered to 80°C, and then 10 parts of acrylic acid, 3 parts of initiator and 3 parts of stabilizer are sequentially added to the melting furnace in corresponding weight proportions, and the stirring equipment is used at a speed of 400r Under the condition of / min, stirring reaction 30min, thereby obtain reaction mass, initiator is ammonium persulfate, and stabilizer is polypropylene oxide;

[0037] S2. Preparation of super absorbent base material: Put the super absorbent base material obtained in step S1, 5 parts of optical cable powder and 3 parts of crosslinking agent into the mixing and stirring equipment respectively, and the temper...

Embodiment 3

[0042] S1. Copolymerization of raw materials: firstly, select 40 parts of purified starch and 20 parts of carboxymethyl cellulose in corresponding weight ratios and add them to a hot melting furnace, add deionized water, and heat at 110°C for 6 minutes to make starch and The cellulose is mixed and becomes a paste, then the furnace temperature is lowered to 90°C, and then 10 parts of acrylic acid, 3 parts of initiator and 3 parts of stabilizer are sequentially added to the melting furnace in corresponding weight proportions, and the stirring equipment is used at a speed of 500r Under the condition of / min, stirring reaction 40min, thereby obtain reaction mass, initiator is ceric ammonium nitrate, and stabilizer is polyethylene oxide;

[0043] S2. Preparation of super absorbent base material: Put the super absorbent base material obtained in step S1, 5 parts of optical cable powder and 3 parts of crosslinking agent into the mixing and stirring equipment respectively, and the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com