Wave-absorbing agent and preparation method thereof

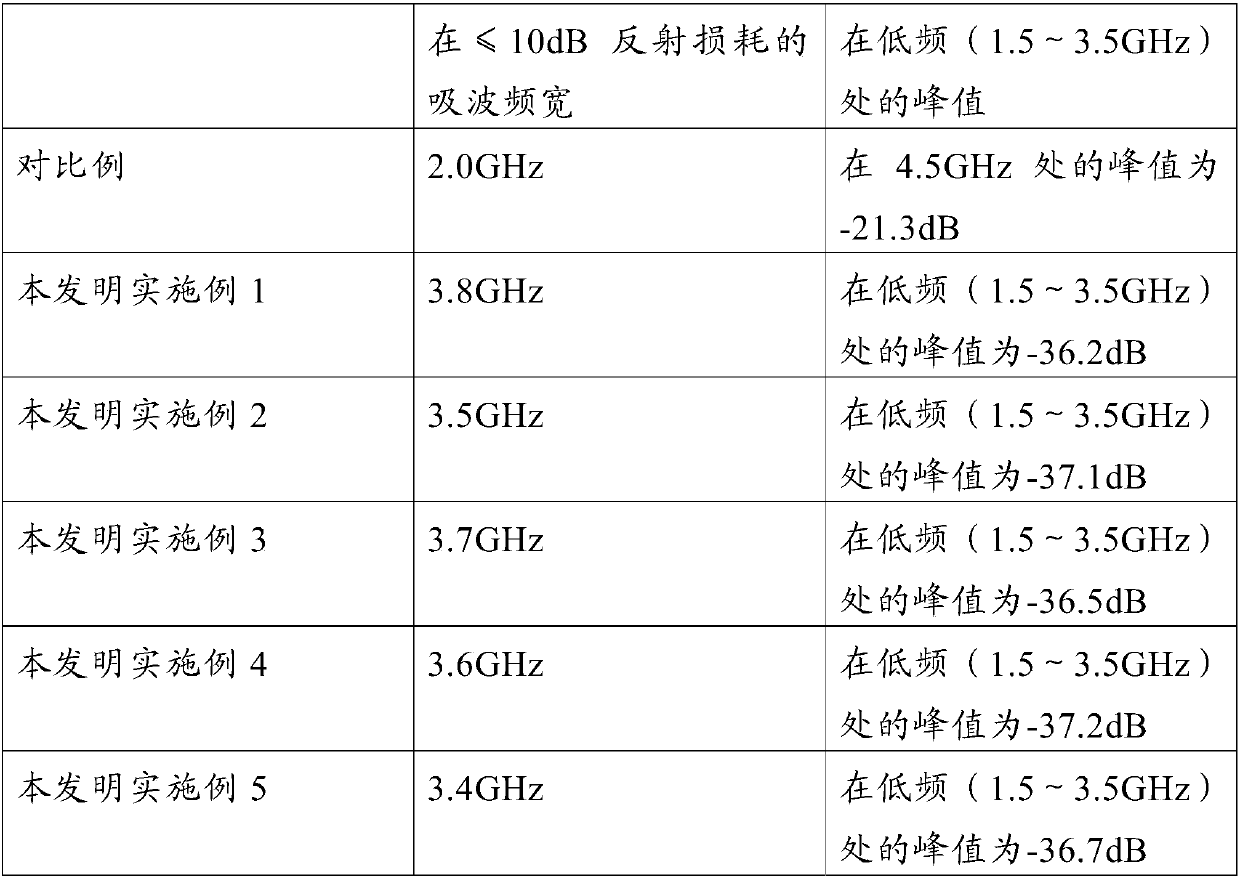

A wave absorbing agent and ball milling technology, applied in the field of wave absorbing materials, can solve the problem that the low frequency wave absorbing performance of radar waves needs to be improved, and achieve the effects of realizing anisotropic characteristics, preventing the spread of electromagnetic information, and improving the magnetic permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of wave absorbing agent provided by the invention comprises the following steps:

[0021] First, carbonyl iron powder, C 1 -C 4 The alcohol solution is mixed uniformly and then ball milled to obtain a slurry. In the above steps, 200-600 parts of carbonyl iron powder and 630-790 parts of C 1 -C 4 Mix the alcohol solution evenly, then put it into a ball mill tank for wet milling, and ball mill in a horizontal planetary ball mill, the speed of the ball mill is 300-450r / min, and the ball milling time is 12-18h. In the horizontal planetary ball mill, the zirconium used The beads are composed of large and medium zirconium beads with diameters of 10mm and 6mm respectively. The mass ratio of the large and medium zirconium beads is 5-20:80-95, and the total weight of the large and medium zirconium beads is 2- 3Kg, the mass ratio of zirconium beads to carbonyl iron powder is 40-100:1, and the carbonyl iron powder after ball milling is a flake structure ...

Embodiment 1

[0025] In parts by mass, mix 200 parts of carbonyl iron powder with 630 parts of ethanol solution evenly, then put them into a ball mill tank for wet milling, and ball mill in a horizontal planetary ball mill with a ball mill speed of 300r / min and a ball milling time of 12h, to obtain slurry. In the horizontal planetary ball mill, the zirconium beads used are composed of large and medium zirconium beads with diameters of 10mm and 6mm respectively. The mass ratio of zirconium beads is 5:80.

[0026] The above slurry is heated and dried at 80° C. for 5 hours to obtain a wave absorbing agent, wherein the thickness of the carbonyl iron powder in the finally obtained wave absorbing agent is about 0.5 μm.

Embodiment 2

[0028] In parts by mass, 600 parts of carbonyl iron powder and 790 parts of methanol solution were evenly mixed, then put into a ball mill tank for wet milling, and ball milled in a horizontal planetary ball mill with a ball mill speed of 450r / min and a ball milling time of 18 hours. In the horizontal planetary ball mill, the zirconium beads used are composed of large and medium zirconium beads with diameters of 10mm and 6mm respectively. The mass ratio of zirconium beads is 20:95.

[0029] The above slurry was heated and dried at 40° C. for 8 hours to obtain a wave absorbing agent, wherein the thickness of the carbonyl iron powder in the finally obtained wave absorbing agent was about 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com