Water-based prefabricated rubber runway and preparation process thereof

A prefabricated, rubber technology, applied in the direction of roads, roads, adhesives, etc., can solve the problems of inability to use water-based polymers, obtain low-toxicity rubber runways, etc., and achieve the effect of saving the amount of binder, meeting the performance standards, and taking into account the toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

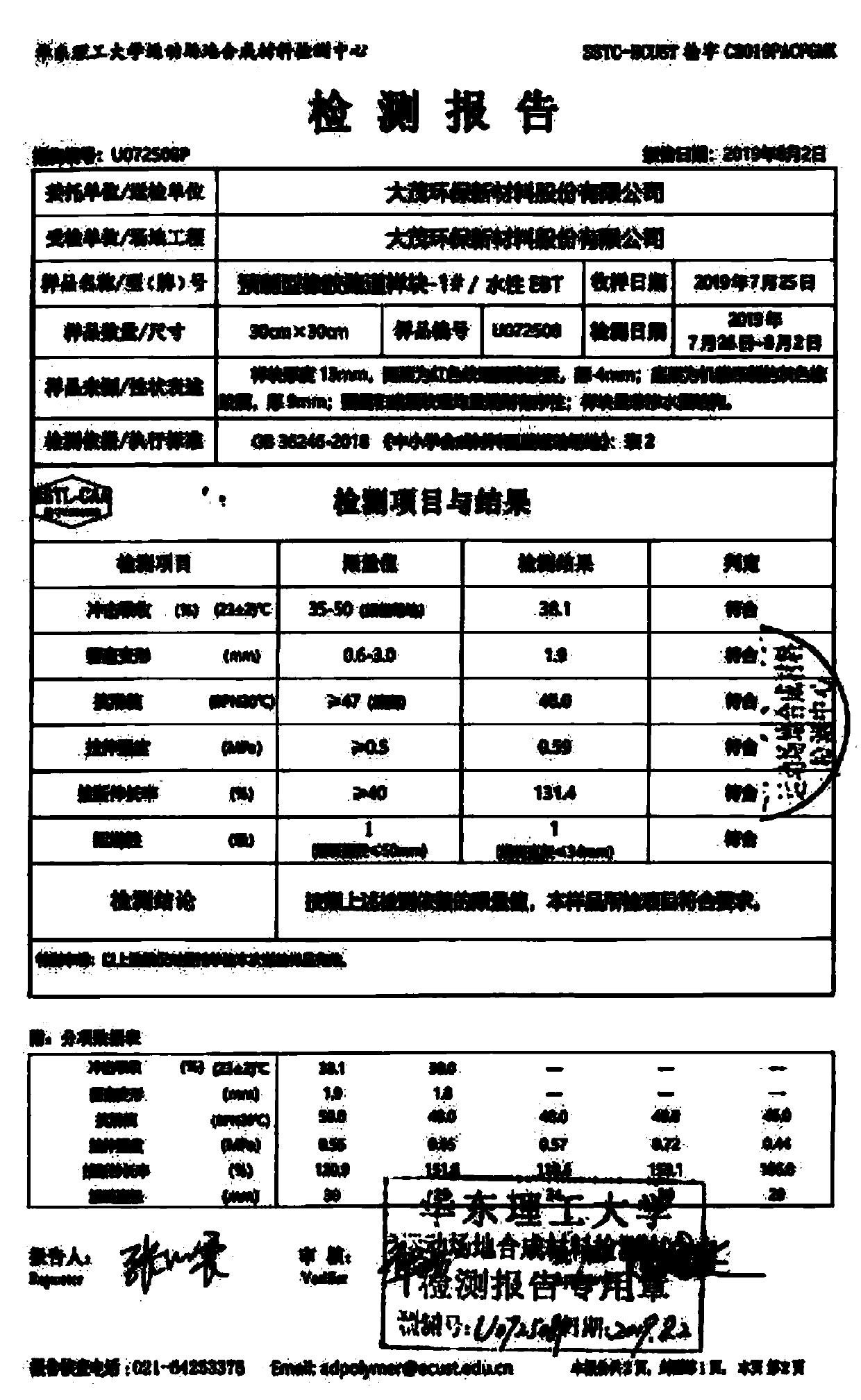

Embodiment 1

[0026] The water-based prefabricated rubber runway of this embodiment includes a wear-resistant layer and an elastic layer superposed up and down. The upper surface of the wear-resistant layer is provided with wear-resistant and anti-skid patterns. The raw materials of the wear-resistant layer are: water-based acrylic acid in parts by weight 5 parts, 10 parts of water-based polyurethane, 75 parts of solid raw materials, 5 parts of iron oxide red and 3 parts of accelerator (the accelerator in this embodiment is a xanthate accelerator), and the solid raw materials are rubber powder and rubber particles, Its size is 5-60 mesh; among them, 5-20 mesh accounts for 40%, and 21-60 mesh accounts for 60%;

[0027] The raw materials of the elastic layer are in parts by weight: 10 parts of water-based polyurethane, 5 parts of water-based acrylic acid, 80 parts of solid raw materials, and 3 parts of accelerator (the accelerator in this embodiment is a xanthate accelerator), wherein The sol...

Embodiment 2

[0041] The water-based prefabricated rubber runway of this embodiment includes a wear-resistant layer and an elastic layer superimposed up and down. The upper surface of the wear-resistant layer has a wear-resistant and anti-skid pattern. The raw materials of the wear-resistant layer are: water-based acrylic acid 10 parts, 10 parts of water-based polyurethane, 88 parts of solid raw materials, 2 parts of iron oxide red and 0.2 parts of accelerator (the accelerator in this embodiment is a xanthate accelerator), and the solid raw materials are rubber powder and rubber particles. The size is 5-60 mesh; of which 5-20 mesh accounts for 40%, and 20-60 mesh accounts for 60%;

[0042] The raw materials of the elastic layer are in parts by weight: 5 parts of water-based polyurethane, 5 parts of water-based acrylic acid, 90 parts of solid raw materials, and 0.2 parts of accelerator (the accelerator in this embodiment is a xanthate accelerator), wherein The solid raw materials are rubber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com