Metal-hydride ultralow-temperature cyclic working system

A hydride, ultra-low temperature technology, applied in non-metallic elements, hydrogen, inorganic chemistry, etc., can solve problems affecting safe use, knocking, instability, etc., achieve energy saving and emission reduction economic benefits, stabilize operating conditions, and create economical effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

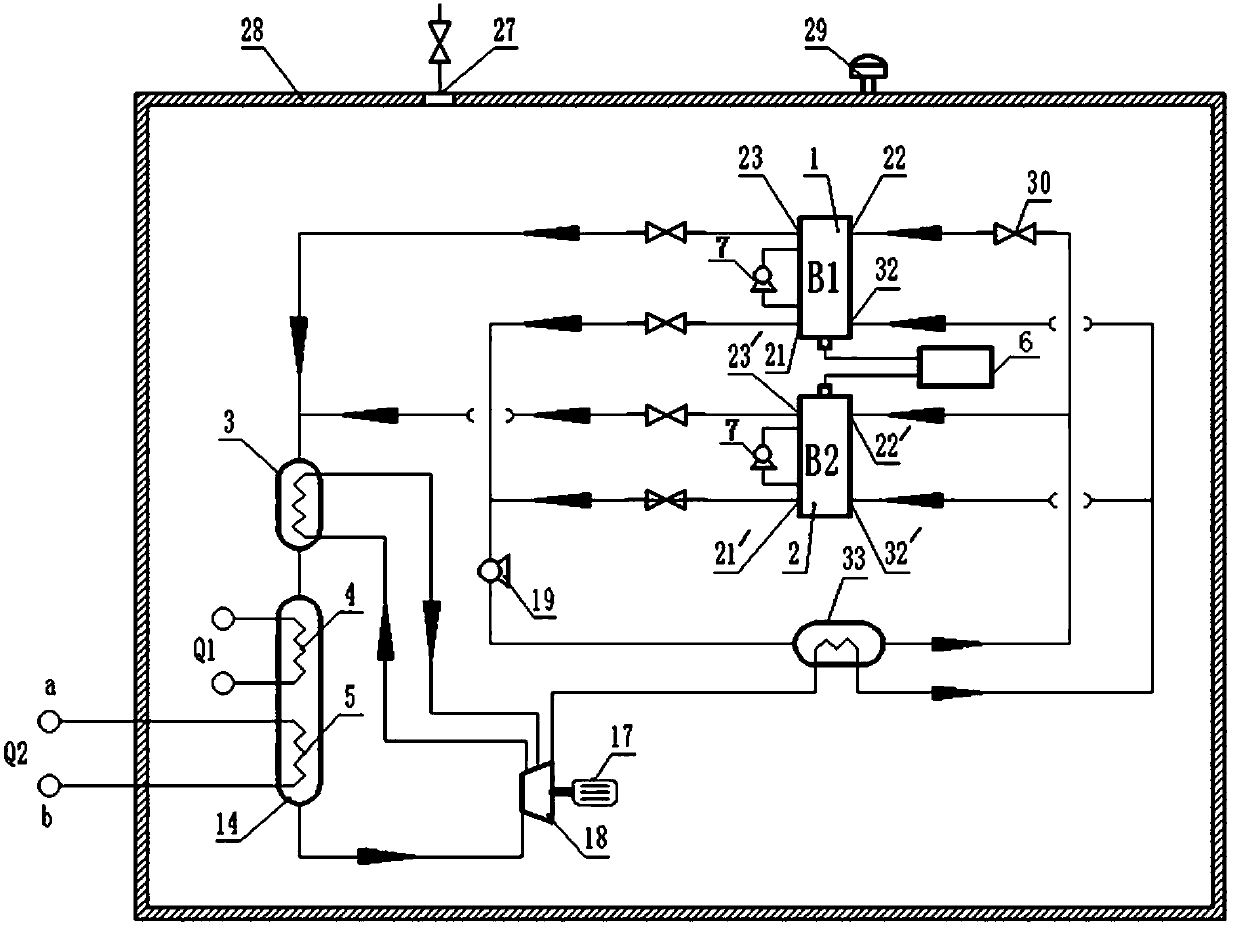

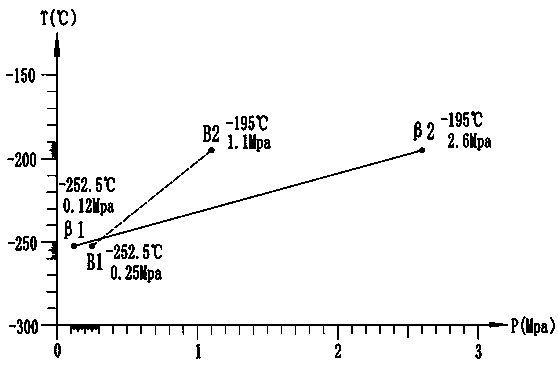

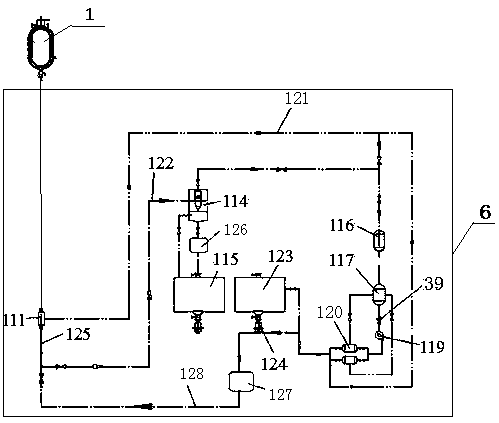

[0029] The embodiment of the present invention provides a metal hydride ultra-low temperature cycle work system, such as figure 1 As shown, the system includes B1 metal hydrogen storage material reaction bed 1, B2 metal hydrogen storage material reaction bed 2, liquid hydrogen high pressure pump 19, air heat exchanger 14, hydrogen expander 18 and generator 17.

[0030] B1 The metal hydrogen storage material reaction bed 1 is provided with a first hydrogen discharge outlet 21 , a first heat exchange outlet 23 , a first liquefaction inlet 32 and a first hydrogen absorption inlet 22 . The B2 metal hydrogen storage materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com