Whispering gallery mode spherical optical microcavity refractive index sensor and measurement device based on surface plasmon

A surface plasmon and refractive index sensor technology, which is applied in the field of optical fiber devices, can solve the problems of complex microbubble cavity preparation methods, lack of universal applicability, and poor practicability, and achieve a wide range of applications, improved refractive index sensitivity, and practicality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

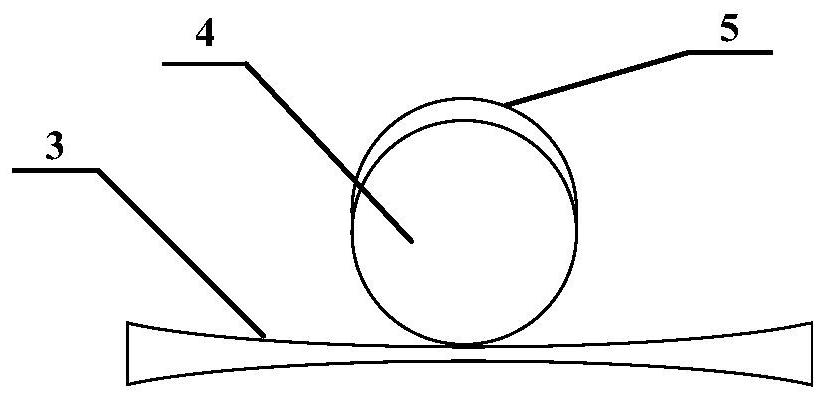

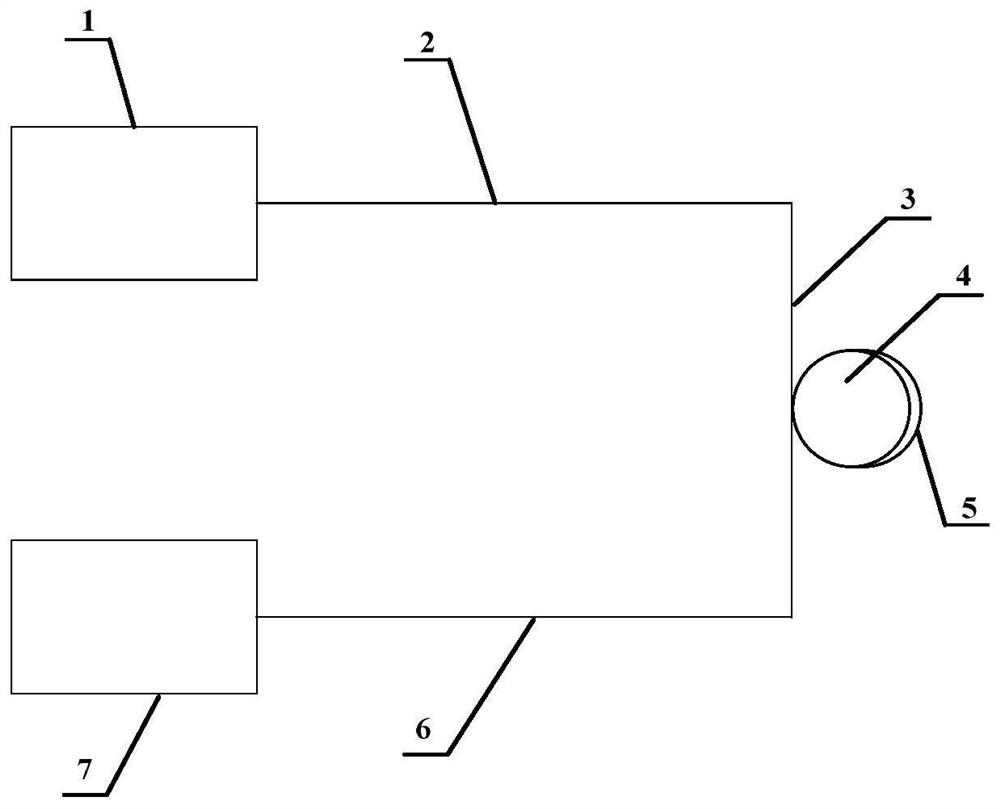

[0024] Such as figure 1 As shown, it is a structural schematic diagram of the surface plasmon-based whispering gallery mode spherical optical microcavity refractive index sensor of the present invention. A whispering gallery mode spherical optical microcavity refractive index sensor based on surface plasmon, comprising micro-nano optical fiber 3, whispering gallery mode spherical optical microcavity 4, micro-nano optical fiber 3 and whispering gallery mode spherical optical microcavity 4 contact coupling; A crescent-shaped gold layer 5 is plated on the surface of the wall-mode spherical optical microcavity 4 to excite surface plasmons and enhance the sensitivity of the spherical optical microcavity to changes in the refractive index of the external medium.

[0025] The micro-nano optical fiber 3 is a low-loss micro-nano optical fiber with a sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com