Marine gas turbine parameter estimation and performance optimization method based on extended Kalman filtering

A technology for expanding Kalman and gas turbines, applied in the field of marine gas turbine control, can solve problems such as the decline of unit performance indicators, shorten the life of the engine, and corrosion of the unit, and achieve the effect of reducing temperature, ensuring safe and stable operation, and improving life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be described in more detail with examples in conjunction with the drawings:

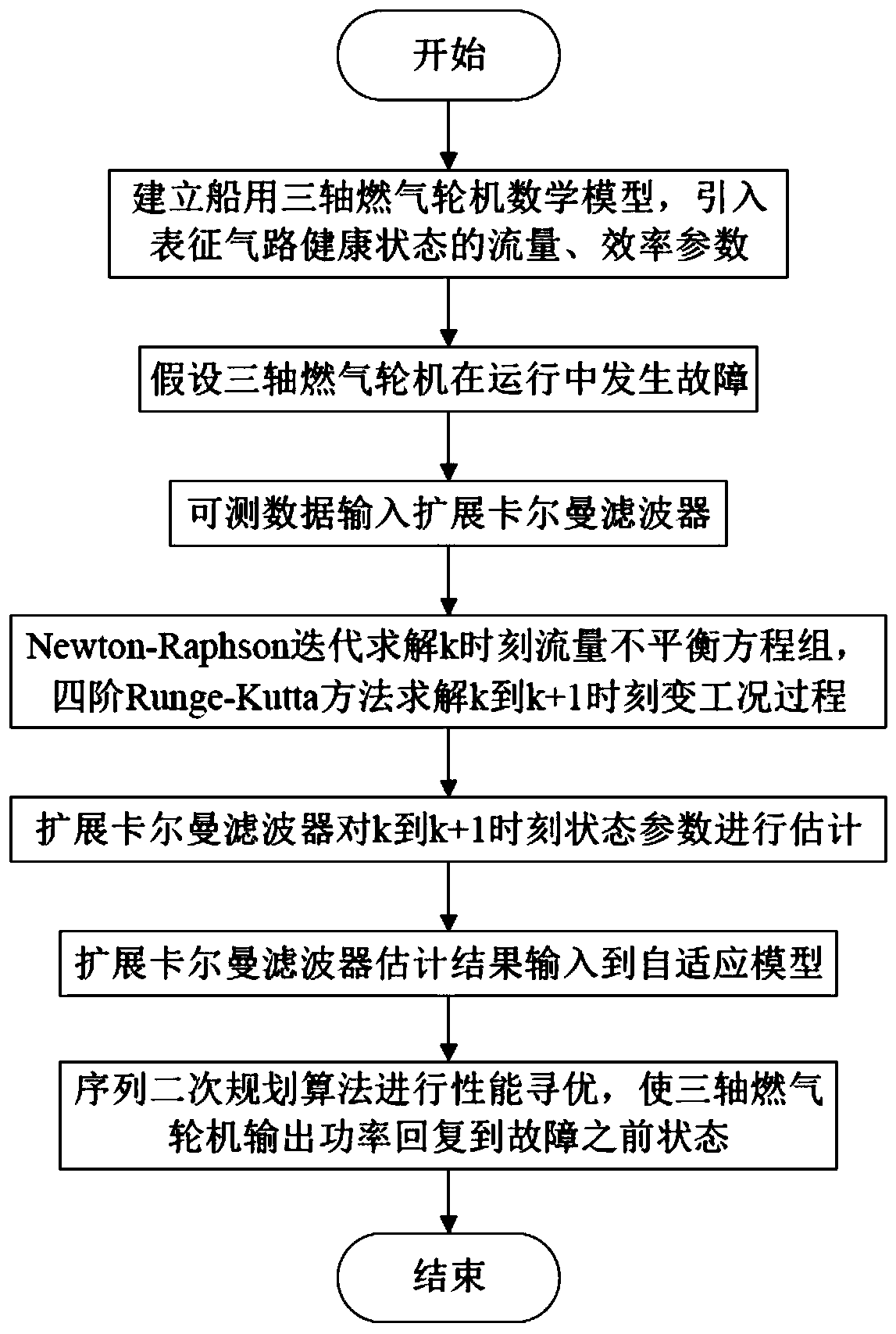

[0031] Combine Figure 1-2 , The purpose of the present invention is achieved through the following solutions:

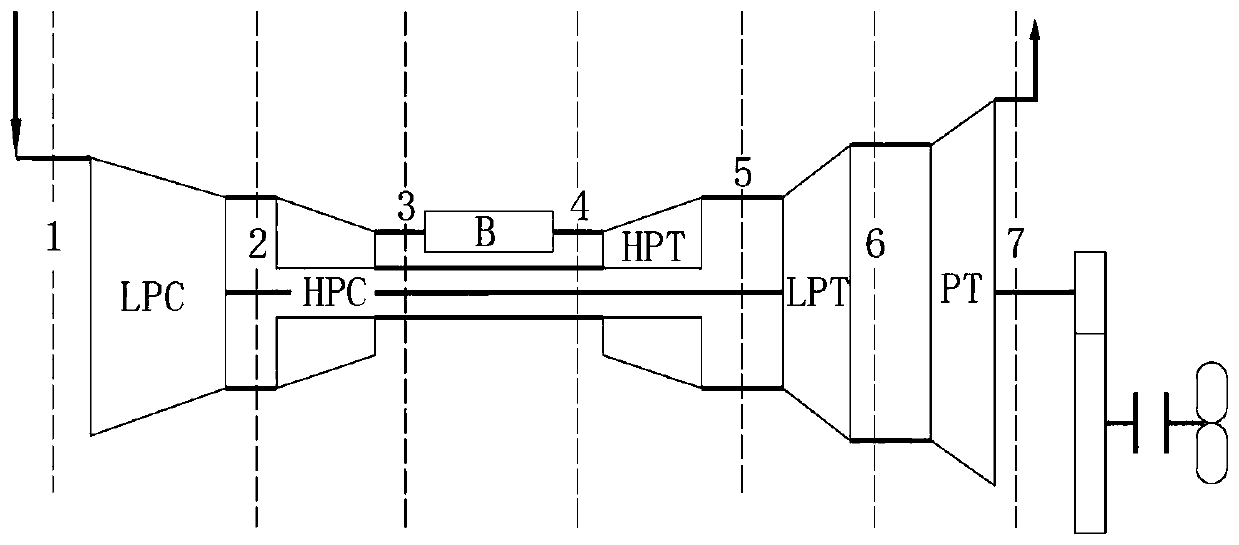

[0032] (1) According to the mathematical model of marine three-axis gas turbine, the variable specific heat method is used to calculate the working parameters and performance of the low-pressure compressor, high-pressure compressor, combustor, high-pressure turbine, low-pressure turbine and power turbine at a given operating point of the three-axis gas turbine parameter;

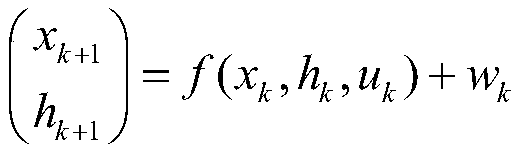

[0033] (2) According to the observation of the measurable parameters of the three-axis gas turbine in the process of gas path failure, when the measurement variance is known, from a series of data with measurement noise, the state parameter change process of the dynamic system is estimated;

[0034] (3) According to the classic Newton-Raphson iterative method to solve the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com