Core-free treatment process for thin-film capacitor

A thin-film capacitor and processing technology, which is applied in the field of thin-film capacitor core-free processing technology, can solve laborious and laborious problems, and achieve the effects of rapid collection and cleaning, reducing time and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

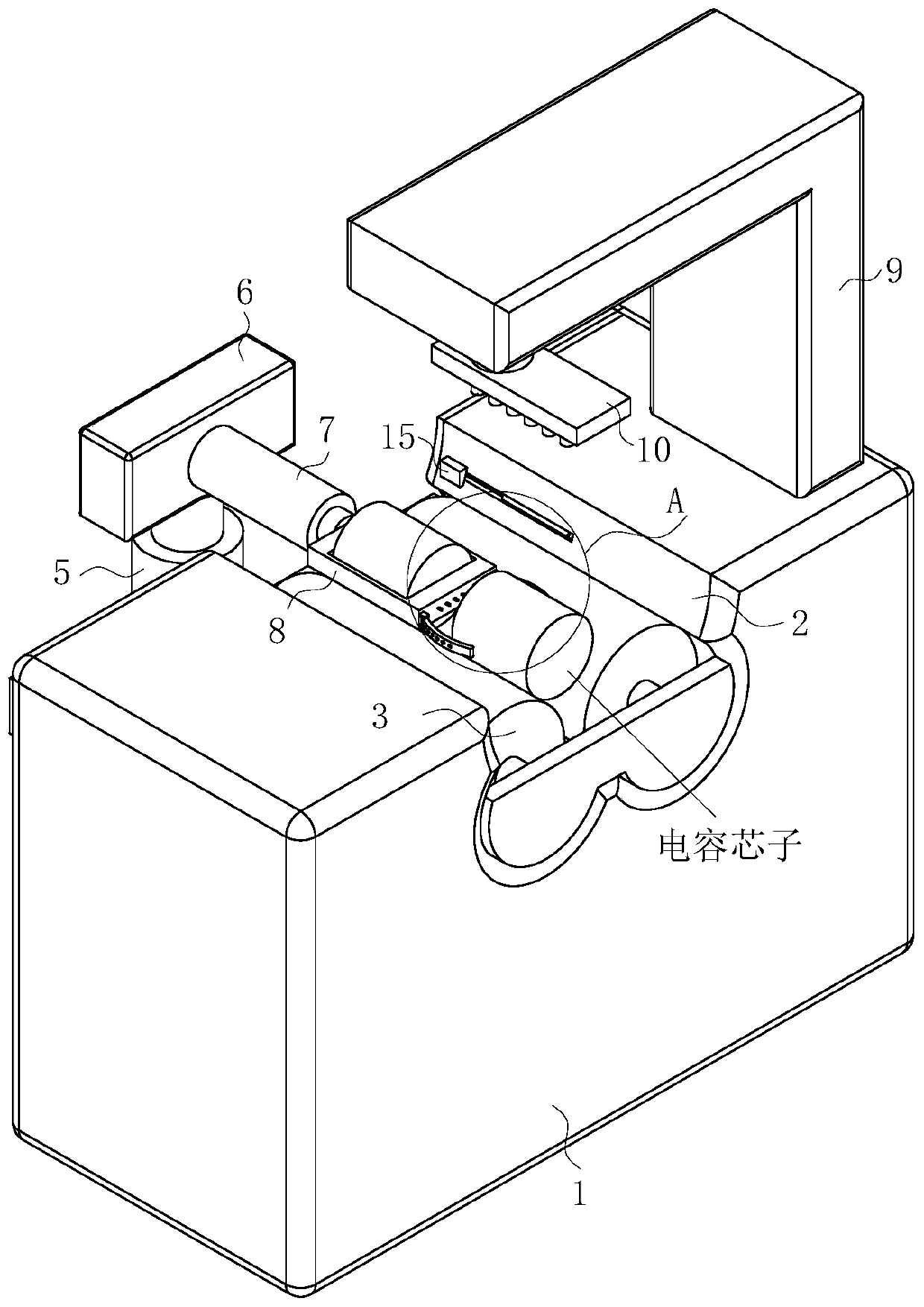

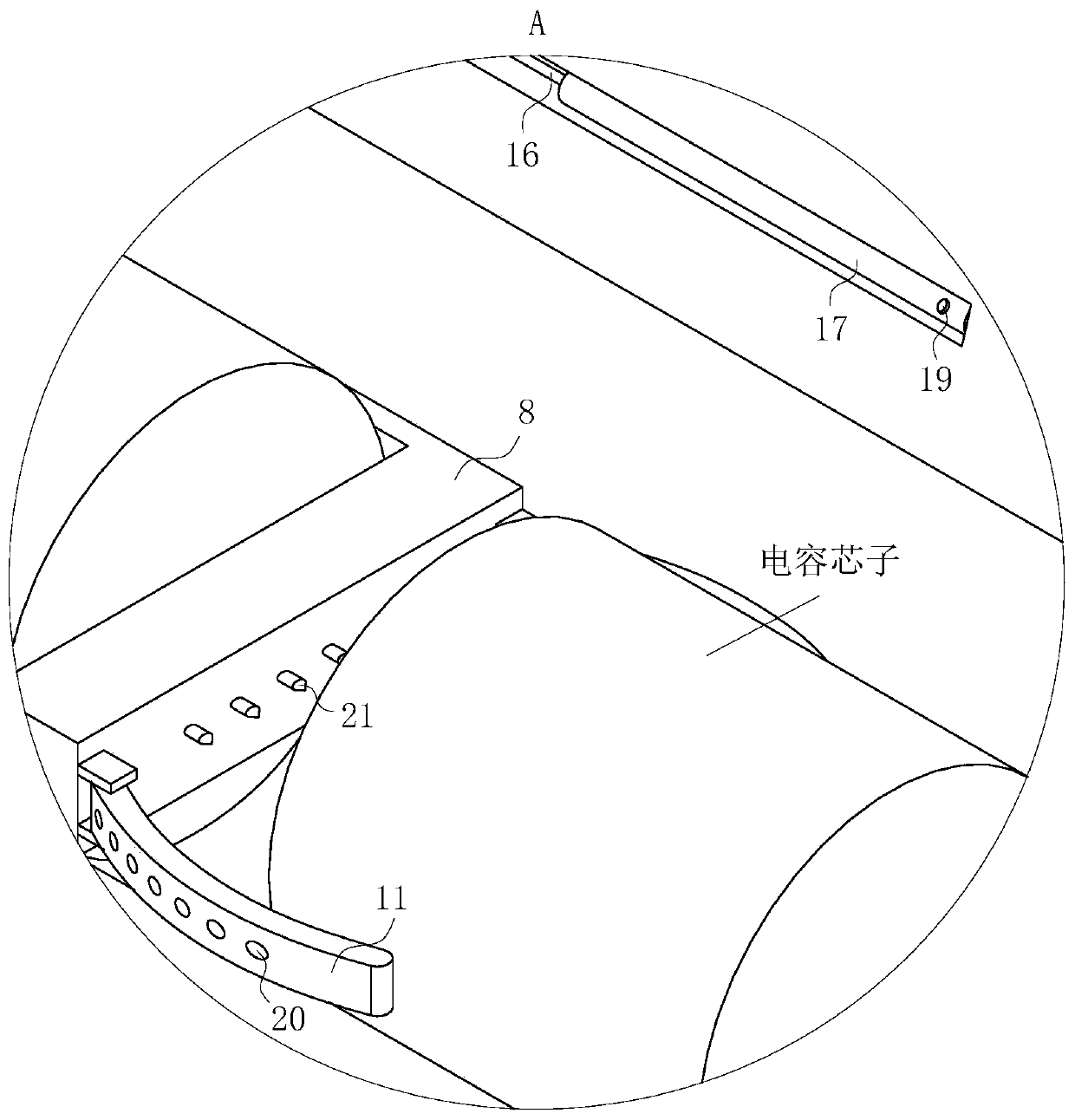

[0026] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following will further elaborate the present invention in conjunction with specific embodiments. Figure 4 view direction.

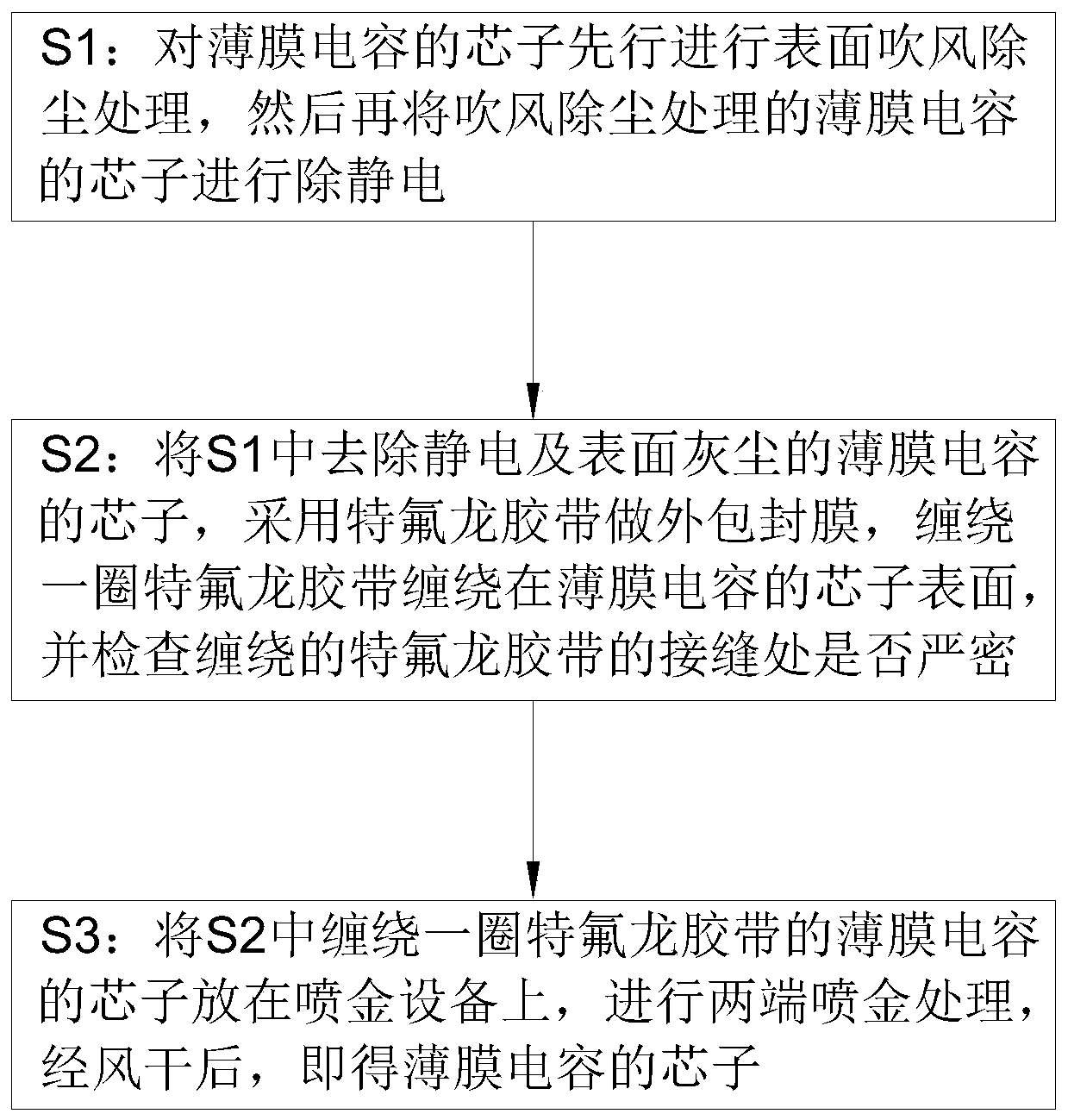

[0027] Such as Figure 1-6 As shown, the thin-film capacitor of the present invention exempts the core processing technology, and this technology comprises the following steps:

[0028] S1: Air-blowing and dust-removing treatment is performed on the core of the film capacitor first, and then the core of the film capacitor subjected to the air-blowing and dust-removing treatment is destaticized; the core of the film capacitor is blown and dust-removed to ensure that Teflon tape is pasted later, especially The viscosity of the fluorocarbon tape can remove static electricity from the core of the film capacitor at the same time, reducing the probability of carrying static electricity on the surface;

[0029] S2: Take the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com