Fiber laser mode stability monitoring device and method

A fiber laser and monitoring device technology, applied in laser monitoring devices, lasers, laser parts and other directions, can solve the problems of low sensitivity and high cost, and achieve the effect of improving sensitivity, low cost, and avoiding device damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

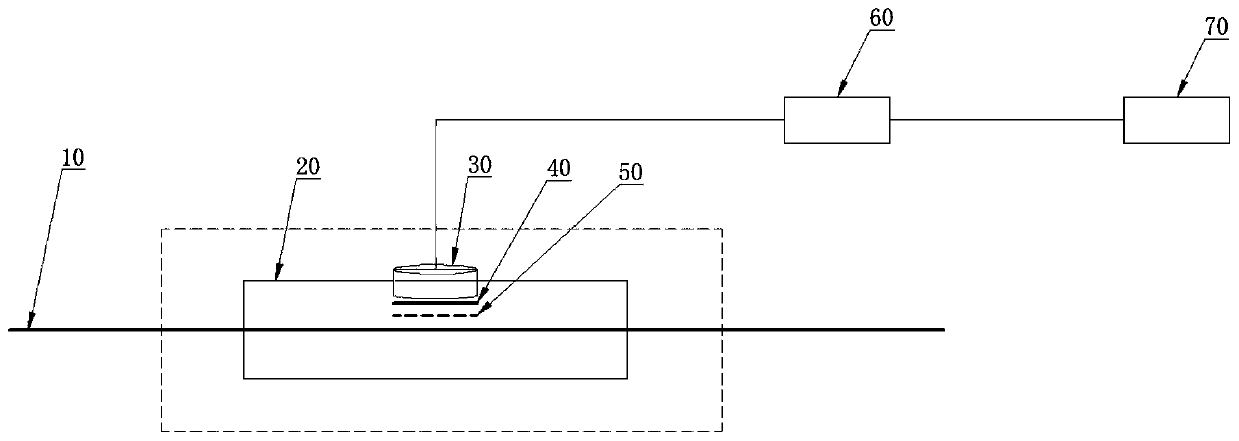

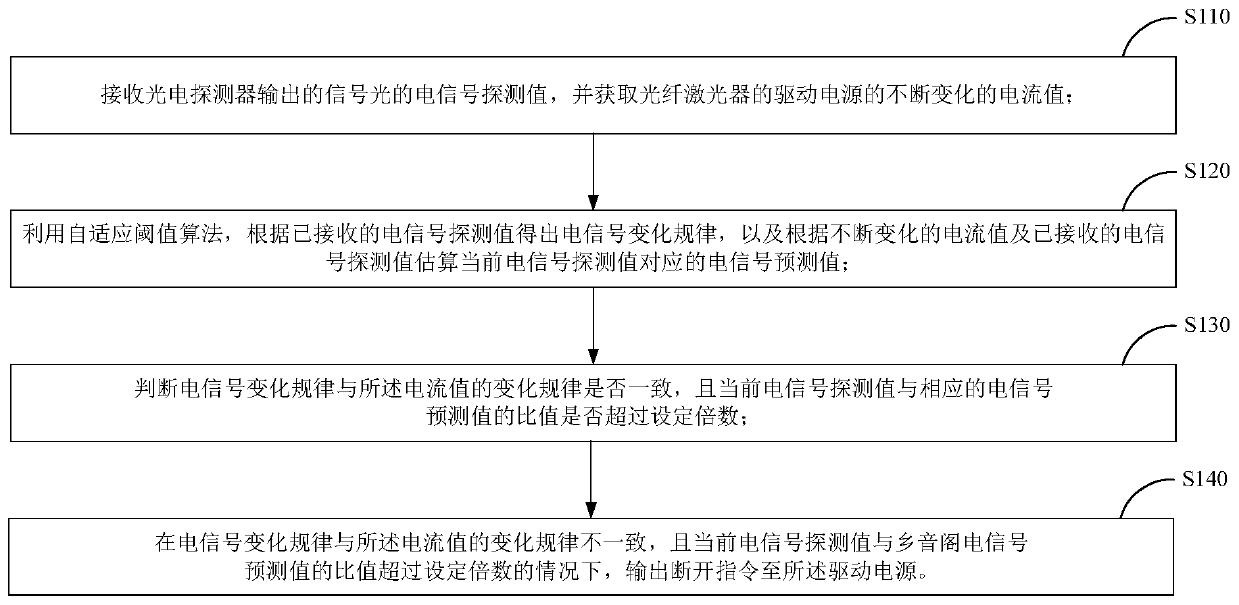

[0066] The monitoring device disclosed in the present invention is used to monitor a high-power narrow-linewidth polarization-maintaining fiber laser; the laser uses a 975nm pump light source, and the output power of the pump light source is greater than 1kw; the fiber uses PM20 / 400 series fiber; the high-power stripper uses It is made of micro-machined corrosion type, and is covered with a glass tube, and a round hole is opened at the upper end of the glass tube; FDS100 or FDS1010 type photodetector is installed in the round hole of the glass tube, and the response band of the photodetector is 400nm~1100nm. The response time is less than 50ns; the light reflectivity of the filter for pump light with a central wavelength of 975nm is greater than 98%, and the transmittance of signal light with a central wavelength of 1064nm is greater than 98%; the attenuation coefficient of the attenuator is 30dB. When the photodetector signal is saturated during the experiment, increase the att...

Embodiment 2

[0069] The monitoring device disclosed in the present invention is used to monitor the high-power thulium-doped fiber laser; the laser uses a 793nm pump light source, and the output power of the pump light source is greater than 1kw; the fiber uses PM25 / 400 series fiber; the high-power stripper uses micro-processing corrosion The FGA20 photodetector is installed in the round hole of the glass tube, and the photodetector has a response band of 1200nm~2600nm, and the response time is less than 50ns; The light reflectivity of the filter for pump light with a central wavelength of 793nm is greater than 98%, and the transmittance of signal light with a central wavelength of 2000nm is greater than 98%; the attenuation coefficient of the attenuator is 30dB. When photoelectricity occurs during the experiment When the detector signal is saturated, the attenuation coefficient of the attenuation sheet is increased to 35dB or 40dB; the control circuit collects the electrical signal of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com