Silicon oxide and carbon composite material and synthesis method thereof

A carbon composite material and synthesis method technology, applied in chemical instruments and methods, separation methods, catalyst carriers, etc., can solve the problems of high cost and complicated preparation methods, and achieve uniform distribution of shell layers and accelerate the transfer of substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

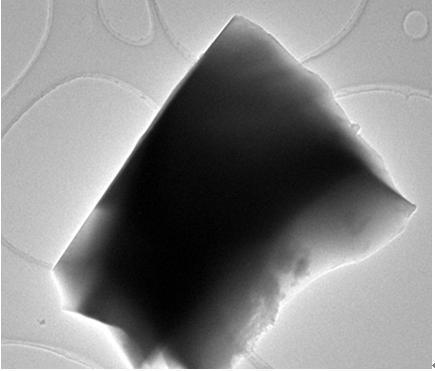

Image

Examples

Embodiment 1

[0046] Embodiment 1: Preparation of different pH buffers

[0047] Configuration of pH4.5 buffer solution: Take 18g of sodium acetate and 9.8mL of glacial acetic acid, dilute with distilled water to a total volume of 1000mL.

[0048] The configuration of pH4.8 buffer solution: mix 19.96g sodium dihydrogen phosphate and 99.8mL distilled water to form A solution; mix 10.14g citric acid and 101.4mL distilled water to form B solution; mix A and B solutions to obtain a buffer solution.

[0049] The configuration of pH 5.0 buffer solution: mix 20.6g sodium dihydrogen phosphate and 103mL distilled water to form A solution; mix 9.7g citric acid and 97mL distilled water to form B solution; mix A and B solutions to obtain a buffer solution.

[0050] Configuration of pH 5.2 buffer solution: Mix 21.44g sodium dihydrogen phosphate and 107.2mL distilled water to form A solution; mix 9.28g citric acid and 92.8mL distilled water to form B solution; mix A and B solutions to obtain a buffer.

...

Embodiment 2

[0053] Mix 10g of glucose, 8g of formaldehyde, and 200mL of distilled water, stir for 1 hour; then place it in a reaction kettle and treat it at 180°C for 12 hours; then wash the solid product with distilled water for 4 times until neutral, dry it at 120°C for 12 hours, and then treat it in nitrogen at 900°C 5h obtains carbon material;

[0054] Take 2.1g of the above carbon in 45mL of ethanol and stir for 0.5h, then ultrasonic treatment for 3h, the frequency of ultrasonic is 1MHz, and the power is 50W / L based on the volume of the solution; then put it in a water bath at 63°C, add 53.5mL of pH4. 8 buffer solution, add 1 mL tetraethyl orthosilicate dropwise under the stirring condition of 120 rpm, stir at the speed of 20 rpm for 5 h after the dropwise addition, and then place it in a water bath at 30 ° C for 12 h; The obtained product was washed 4 times with distilled water to neutrality, dried at 120°C for 12h, and heat-treated at 260°C for 3h to obtain SiO 2 / carbon composit...

Embodiment 3

[0056] Mix 10g of glucose, 2.4g of formaldehyde, and 400mL of distilled water, stir for 0.2h; then put it in a reaction kettle for 4h at 200°C; then wash the solid product with distilled water 4 times until neutral, dry at 120°C for 12h, and then 1000°C in nitrogen ℃ treatment for 4h to obtain carbon materials;

[0057] Take 2g of the above carbon in 20mL of ethanol and stir for 0.2h, then sonicate for 2h, the frequency of the ultrasonic is 15KHz, the power is 100W / L based on the volume of the solution; then put it in a water bath at 70°C, add 22mL of pH5.0 buffer solution, add 0.4 mL ethyl orthosilicate dropwise under the stirring condition of 280 rpm; after the dropwise addition, stir at the speed of 50 rpm for 2 h, and then place it in a water bath at 25 ° C for 6 h; The product was washed 4 times with distilled water to neutrality, dried at 120°C for 12h, and treated at 280°C for 2h to obtain SiO 2 / carbon composite material, the obtained sample number is CL2, and the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com