Thermoplastic composite, composite part and composite part manufacturing method

A composite material, thermoplastic technology, applied in the direction of coating, can solve the problems of heavy weight and poor mechanical properties, achieve the effect of light weight, excellent mechanical properties, and improve the shear strength between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A continuous carbon fiber reinforced thermoplastic resin (polyamide-nylon 6, melting point of 225°C) prepreg is selected, and the weight ratio of resin to fiber in the prepreg is 85:15. By laser cutting, the prepreg is cut along the direction perpendicular to the fiber axis, and the prepreg is cut into a reinforcement sheet with a thickness of 0.5mm. The fiber length in the reinforcement sheet is within the range of 0.1-3mm. Normal distribution, the fibers basically extend along the thickness direction in the reinforcing sheet;

[0055] Select the dry cloth of carbon fiber uniaxial cloth, and coat the surface treatment agent mixed by graphene oxide slurry and oxidized carbon black on the surface of the dry cloth to complete the surface modification of the dry cloth;

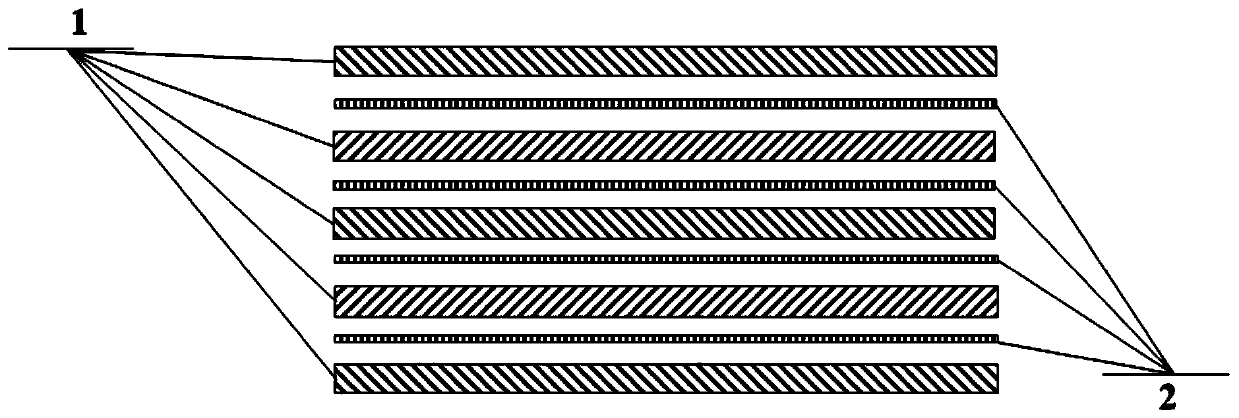

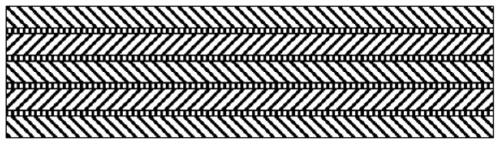

[0056] Lay 12 layers of carbon fiber dry cloth after surface modification treatment in an orthogonal manner (that is, the laying angle between adjacent dry cloth layers is 90°), and lay the manufactured re...

Embodiment 2

[0060] Manufacture composite material 3 according to the step of embodiment 1, and embodiment 1 is different: the ratio of the weight content of resin and fiber in the prepreg is 50:50.

Embodiment 3

[0062] Manufacture composite material 3 according to the steps of Example 1, the difference from Example 1 is that the prepreg is cut into a reinforcement sheet with a thickness of 1.2mm, and the fiber length in the reinforcement sheet is normal within the range of 0.03-7mm distributed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com