Liquid-phase bulk continuous polymerization method of 1-butene and poly-1-butene

A liquid phase bulk, polymerization method technology, applied in the field of olefin polymerization, can solve the problems of low polymerization activity, difficult transportation, sticky polymerization system, etc., and achieves the effect of simple polymerization process, flexible and convenient operation, and optimized process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

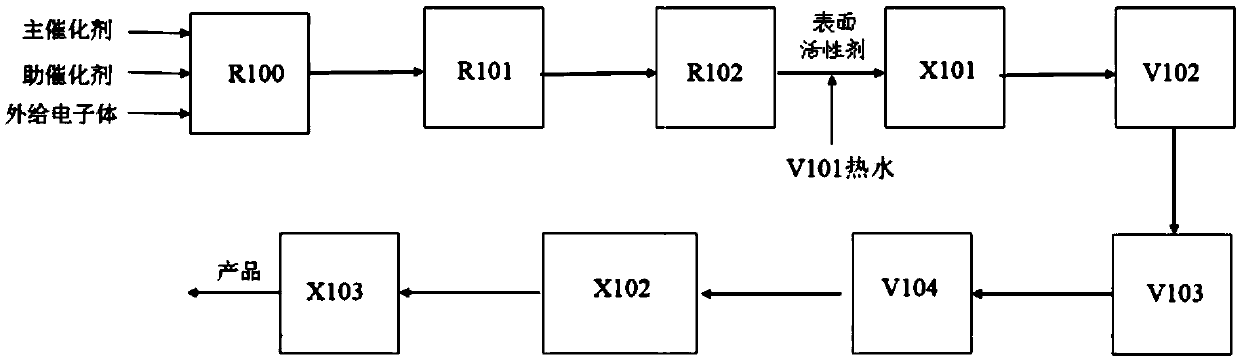

[0057] Such as figure 1 Shown, the main catalyst (MgCl 2 / TiCl 4 Supported Ziegler-Natta catalyst), co-catalyst (triethylaluminum) and external electron donor (dicyclopentyldimethoxysilane) in the pre-complexation tank R100 after 6 ℃, 8min pre-complexation The catalyst slurry is continuously fed into the liquid phase reactor IR101, the flow rate of triethylaluminum (TEA) is 6.33g / hr, the flow rate of dicyclopentyldimethoxysilane (DCPMS) is 0.3g / hr, and the flow rate of the main catalyst is 0.6 g / hr with a TEA / DCPMS ratio of 50 (mol / mol).

[0058] In this example, a liquid phase reactor IR101 and a liquid phase reactor IIR102 connected in series are used for olefin polymerization. The catalyst slurry and 1-butene are continuously introduced into the liquid phase reactor IR101 for the first olefin polymerization reaction, and the obtained first olefin polymerization reaction product and 1-butene are continuously introduced into the liquid phase reactor IIR102 for the second o...

Embodiment 2

[0060] The catalyst used in embodiment 2, pre-complexation, polymerization process conditions and auxiliary agent formula and add-on are the same as embodiment 1. The difference from Example 1 is that the surfactant is replaced by the same volume of oleyl ether, and the analysis results of the obtained polymer powder are shown in Table 1.

Embodiment 3

[0062] The catalyst used in embodiment 3, pre-complexation, polymerization process conditions and auxiliary agent formula and addition are the same as embodiment 1. The difference from Example 1 is that the surfactant is replaced by the same volume of cocamidopropyl betaine, and the analysis results of the obtained polymer powder are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| isotactic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com