Non-oriented electrical steel and preparation method thereof

A technology of oriented electrical steel and electrical steel, which is applied in the fields of electrical steel metallurgy and iron and steel metallurgy, can solve the problems of insufficient performance and high production cost of low-silicon non-oriented electrical steel, and achieve the effects of improved magnetic properties, improved performance, and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A production process of low-silicon non-oriented electrical steel. Including the following process steps:

[0029] S1. The converter adopts a 120-ton converter, the mass percentage of molten iron charged: [S]: 0.001%; the mass percentage of the end point of converter smelting: C: 0.0025%, S: 0.0021%, P: 0.011%, [O]: 625ppm; final slag R: 3.3, the converter requires "bare steel" tapping, and 400kg of lime is added after tapping 1 / 5 of the steel;

[0030] S2. The temperature of the molten steel is 1629° C. after the temperature rise of the LF furnace is completed.

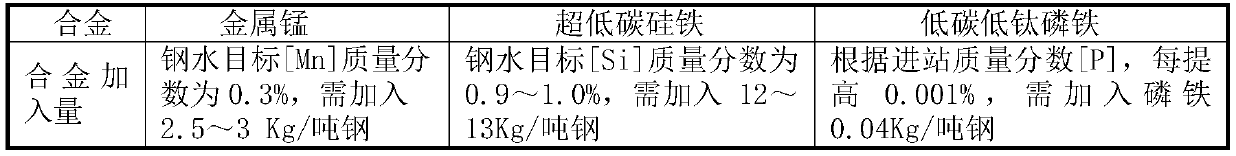

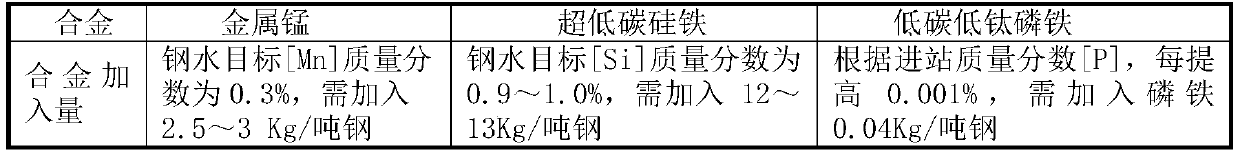

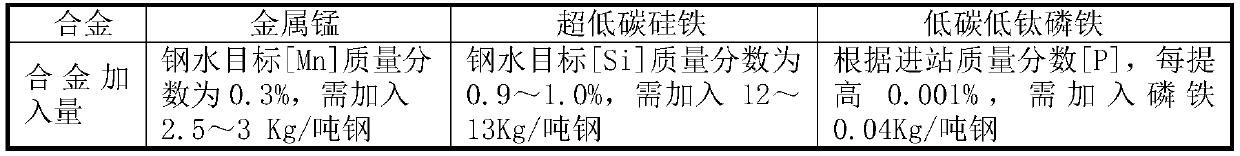

[0031] S3, RH vacuum treatment for 36min, circulating argon gas flow rate 900Nl / min, vacuum degree 1.8Mbar; alloying sequence is low-carbon low-titanium ferrophosphorus, aluminum, ultra-low carbon ferrosilicon, metal manganese, and the adding time interval is ≥3min;

[0032] Aluminum content

[0033] [O], ppm 300 400 500 600 700 Aluminum content, Kg 495 520 545 570 595

[0034...

Embodiment 2

[0041] A production process of low-silicon non-oriented electrical steel. Including the following process steps:

[0042] S1. The converter adopts a 120-ton converter, the mass percentage of molten iron charged: [S]: 0.0008%; the mass percentage of the end point of converter smelting: C: 0.0021%, S: 0.0024%, P: 0.012%, [O]: 850ppm; final slag R: 3.4, the converter requires "bare steel" tapping, and 450kg of lime is added after tapping 1 / 5 of the steel;

[0043] S2. After the temperature rise of the molten steel in the LF furnace is completed, the temperature of the molten steel is 1631°C, and 100kg of high-alumina slag is added to the slag surface of the ladle to modify the top slag;

[0044] S3, RH vacuum treatment for 38 minutes, circulating argon gas flow rate 1000Nl / min, vacuum degree 1.9Mbar; alloying sequence is low-carbon and low-titanium ferrophosphorus, aluminum, ultra-low carbon ferrosilicon, metal manganese, and the adding time interval is ≥3min;

[0045] Aluminum...

Embodiment 3

[0054] A production process of low-silicon non-oriented electrical steel. Including the following process steps:

[0055] S1. The converter adopts a 120-ton converter, the mass percentage of molten iron charged: [S]: 0.0008%; the mass percentage of the end point of converter smelting: C: 0.0023%, S: 0.0025%, P: 0.012%, [O]: 702ppm; final slag R: 3.38, the converter requires "bare steel" tapping, and 500kg of lime is added after tapping 1 / 5 of the steel;

[0056] S2. The temperature of the molten steel is 1634°C after the temperature rise of the LF furnace;

[0057] S3, RH vacuum treatment for 41 minutes, circulating argon gas flow rate 1200Nl / min, vacuum degree 1.96Mbar; alloying sequence is low-carbon low-titanium ferrophosphorus, aluminum, ultra-low carbon ferrosilicon, metal manganese, and the adding time interval is ≥3min;

[0058] Aluminum content

[0059] [O], ppm 300 400 500 600 700 Aluminum content, Kg 495 520 545 570 595

[0060] Alloyi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iron loss value | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com