Warm antibacterial garment material

A technology for fabrics and clothing, applied in the field of warm antibacterial clothing fabrics, can solve the problems of affecting the service life of fabrics, decline in antibacterial properties, poor compatibility, etc., achieve high preparation efficiency and yield, avoid performance deterioration, and improve The effect of thermal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

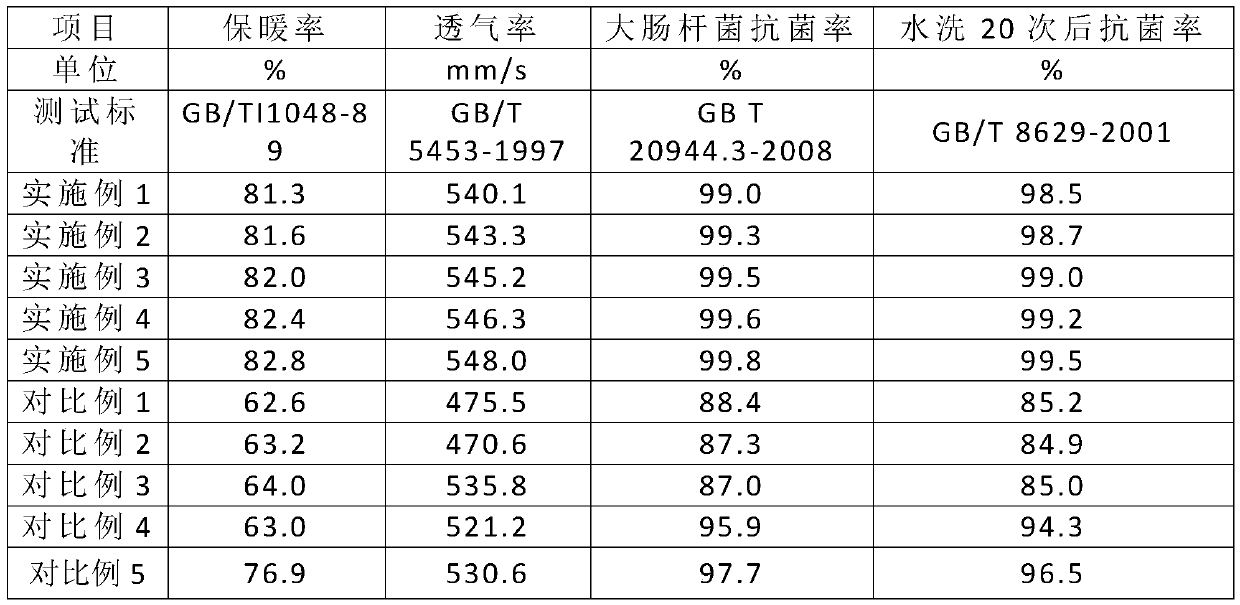

Examples

Embodiment 1

[0029] A warm antibacterial clothing fabric, characterized in that, the clothing fabric is obtained by weaving warp yarns and weft yarns, the warp yarns are antibacterial heat preservation fiber yarns, and the weft yarns are kapok fiber yarns; the raw material for preparing the antibacterial heat preservation fiber yarn Including the following weight percentages of each component: 4,7,13,16,21,24-hexaoxo-1,10-diazabicyclo[8.8.8] hexadecane / cyclophosphamide polycondensate 20 parts , 40 parts of allylbenzenethiazole / triethoxysilylpropyl maleic acid / chlorogenic acid copolymer, 5 parts of ZnO mesoporous nanofibers.

[0030] The preparation method of the 4,7,13,16,21,24-hexaoxo-1,10-diazabicyclo[8.8.8] hexadecane / cyclophosphamide polycondensate includes the following steps: 4, 7,13,16,21,24-hexaoxo-1,10-diazabicyclo[8.8.8] hexadecane and cyclophosphamide were added to dimethyl sulfoxide, and the reaction was stirred at 40°C for 4 hours. The dimethyl sulfoxide was removed by rotary ev...

Embodiment 2

[0035] A warm antibacterial clothing fabric, characterized in that, the clothing fabric is obtained by weaving warp yarns and weft yarns, the weft yarns are antibacterial warmth fiber yarns, and the warp yarns are kapok fiber yarns; the raw material for preparing the antibacterial warmth fiber yarns Including the following components by weight percentage: 4,7,13,16,21,24-hexaoxo-1,10-diazabicyclo[8.8.8] hexadecane / cyclophosphamide polycondensate 23 parts , Allylbenzenethiazole / triethoxysilylpropyl maleic acid / chlorogenic acid copolymer 45 parts, ZnO mesoporous nanofibers 6 parts.

[0036] The preparation method of the 4,7,13,16,21,24-hexaoxo-1,10-diazabicyclo[8.8.8] hexadecane / cyclophosphamide polycondensate includes the following steps: 4, 7,13,16,21,24-hexaoxo-1,10-diazabicyclo[8.8.8] hexadecane and cyclophosphamide were added to N,N-dimethylformamide at 45℃ The reaction was stirred for 4.5 hours, then the N,N-dimethylformamide was removed by rotary evaporation, and the produc...

Embodiment 3

[0041] A warm antibacterial clothing fabric, characterized in that, the clothing fabric is obtained by weaving warp yarns and weft yarns, the warp yarns are antibacterial heat preservation fiber yarns, and the weft yarns are kapok fiber yarns; the raw material for preparing the antibacterial heat preservation fiber yarns Including the following weight percentages of each component: 4,7,13,16,21,24-hexaoxo-1,10-diazabicyclo[8.8.8] hexadecane / cyclophosphamide polycondensate 25 parts , Allylbenzenethiazole / triethoxysilylpropyl maleic acid / chlorogenic acid copolymer 50 parts, ZnO mesoporous nanofibers 7 parts.

[0042] The preparation method of the 4,7,13,16,21,24-hexaoxo-1,10-diazabicyclo[8.8.8] hexadecane / cyclophosphamide polycondensate includes the following steps: 4, 7,13,16,21,24-hexaoxo-1,10-diazabicyclo[8.8.8] hexadecane and cyclophosphamide were added to N,N-dimethylacetamide at 50℃ The reaction was stirred for 5 hours, then the N,N-dimethylacetamide was removed by rotary ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| warmth retention rate | aaaaa | aaaaa |

| warmth retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap