Regularization sparse filtering method suitable for gear fault diagnosis under variable rotating speed

A sparse filtering and fault diagnosis technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as single mapping between signals and fault types, reduce the generalization ability of data-driven models, and eliminate Influence and realize the effect of fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

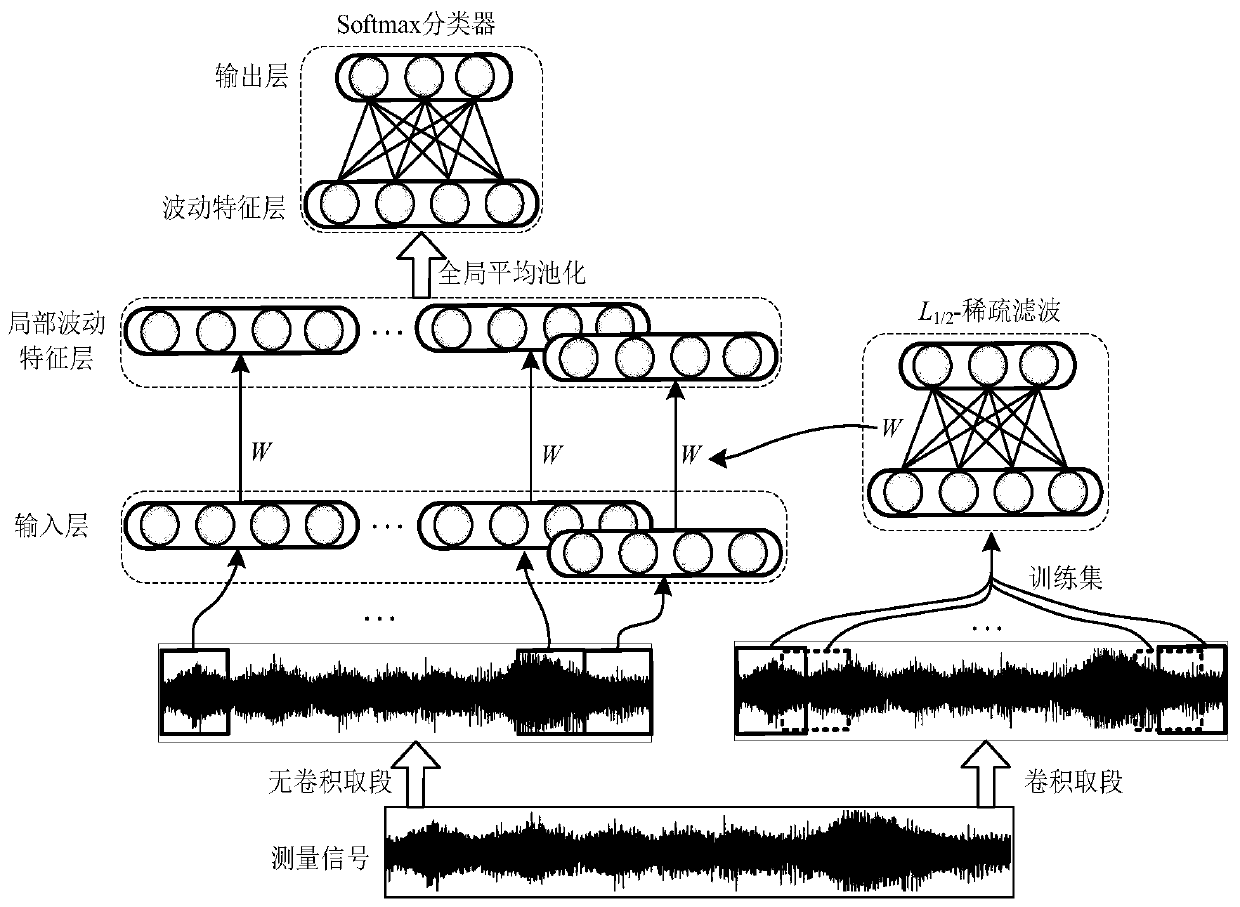

[0030] combine figure 1 , a regularized sparse filtering method suitable for gear fault diagnosis at variable speeds, including the following steps:

[0031] (1) Set different gear health statuses, and manually adjust the frequency converter to control the motor speed to fluctuate randomly within a certain range, thereby obtaining variable speed conditions, and collecting vibration signals of different faulty gears under variable speed conditions; using the original The vibration signal is used as a training sample, and the Z-segment signal is collected from the training sample by the convolution segment method, and these segments form the training set ,in is the jth segment containing N in data points, N in The input dimension used to represent sparse filtering, N out Indicates the output dimension.

[0032] (2) Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com