Catalyst slurry of proton exchange film fuel cell and application thereof

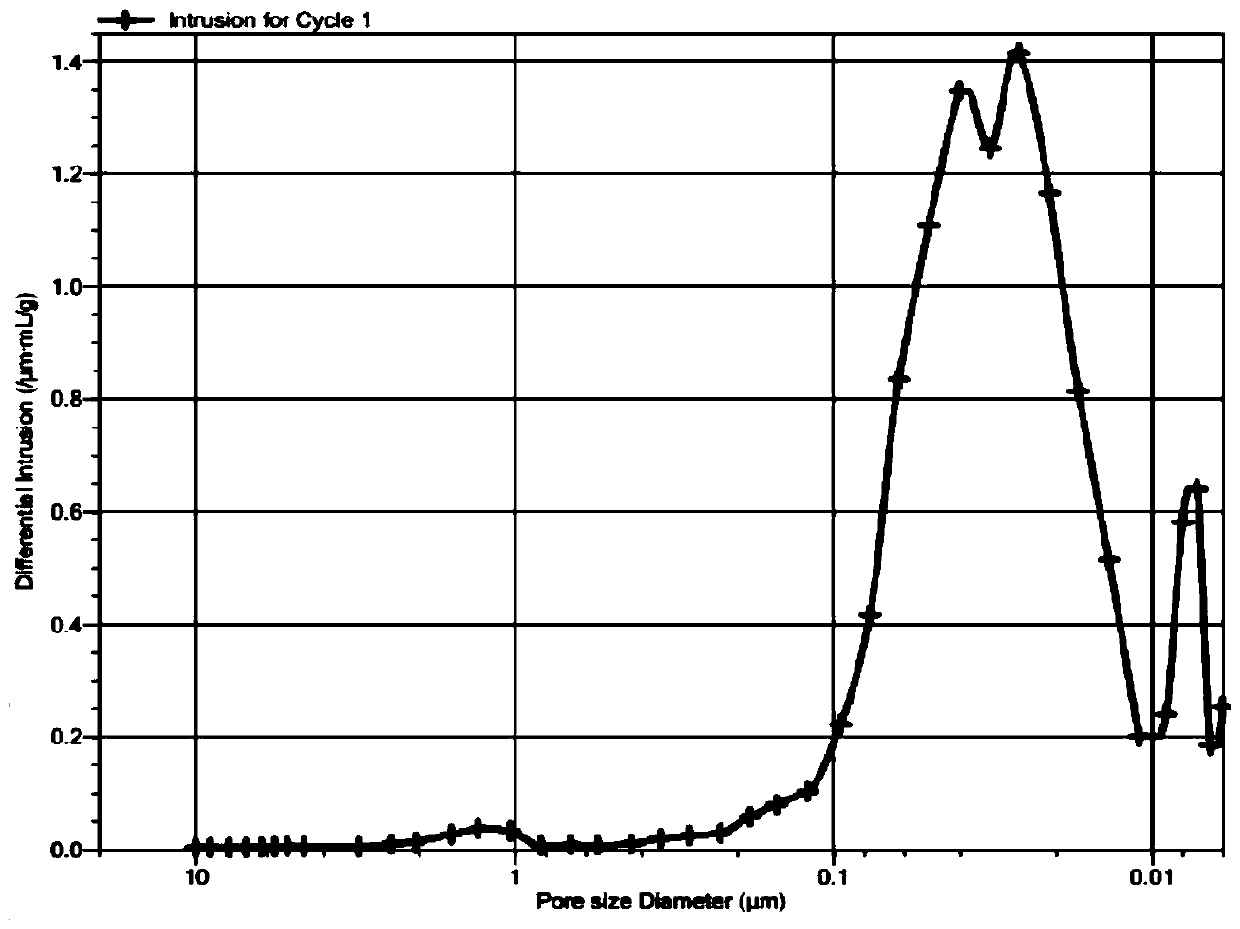

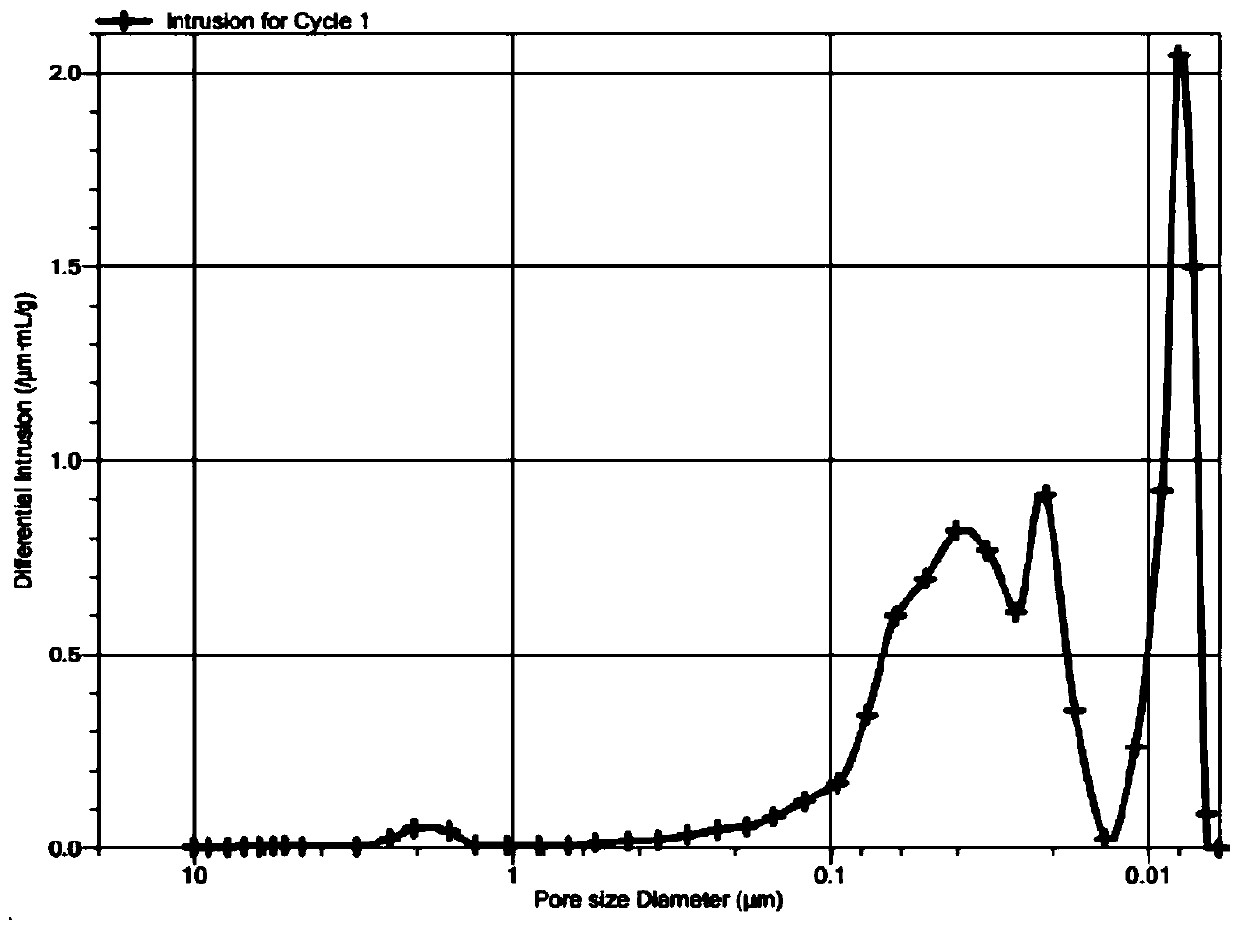

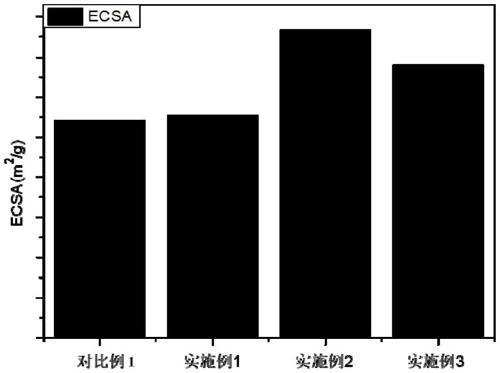

A proton exchange membrane and fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of reducing the conductivity and hydrophobicity of the catalytic layer, affecting the life of the membrane electrode, etc., and achieve the electrochemical active area and The effect of improving the mass specific activity, optimizing the gas/liquid/solid three-phase interface, and optimizing the pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] According to the experimental plan formulated in the early stage, 2g of catalyst Pt / C was accurately weighed, and the mass of perfluorosulfonic acid resin solution was added to be 16 grams. The mass ratio of the resin solution I (EW700) to the resin solution II (EW1100) was 0.1, so 1.45 g of resin solution I was added, and 14.55 g of resin solution II was added. Generally, the solid content of perfluorosulfonic acid resin solutions with different EW values is formulated to a unified value5 wt %, can be added after mixing perfluorosulfonic acid resin solutions with different EW values or sequentially. Then 50 g of low-boiling point alcohol isopropanol and 70 g of deionized water were added in sequence, and then ultrasonically mixed for 20 minutes to form the catalytic layer slurry.

Embodiment 2

[0040] According to the experimental plan formulated in the early stage, 2g of catalyst Pt / C was accurately weighed, the mass of the added perfluorosulfonic acid resin solution was 16 grams, and the mass ratio of the resin solution I (EW700) to the resin solution II (EW1100) was 0.5, Therefore, 5.33 g of resin solution I and 10.67 g of resin solution II were added. Then 50 g of low-boiling point alcohol isopropanol and 70 g of deionized water were added in sequence, and then ultrasonically mixed for 20 minutes to form the catalytic layer slurry.

Embodiment 3

[0042] According to the experimental plan formulated in the early stage, 2g of catalyst Pt / C was accurately weighed, the mass of perfluorosulfonic acid resin added was 16 grams, and the mass ratio of the resin solution I (EW700) to the resin solution II (EW1100) was 10, so 14.55 g of resin solution I was added, and 1.45 g of resin solution II was added. Then 50 g of low-boiling point alcohol isopropanol and 70 g of deionized water were added in sequence, and then ultrasonically mixed for 20 minutes to form the catalytic layer slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com