Lead-free solder alloy, electronic circuit mounting board, and electronic control device

A technology for electronic circuits and mounting substrates, which is applied in the direction of assembling printed circuits with electrical components, manufacturing tools, metal processing equipment, etc., can solve problems such as difficulty in suppressing the development of cracks, and achieve the effects of suppressing the development of cracks and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

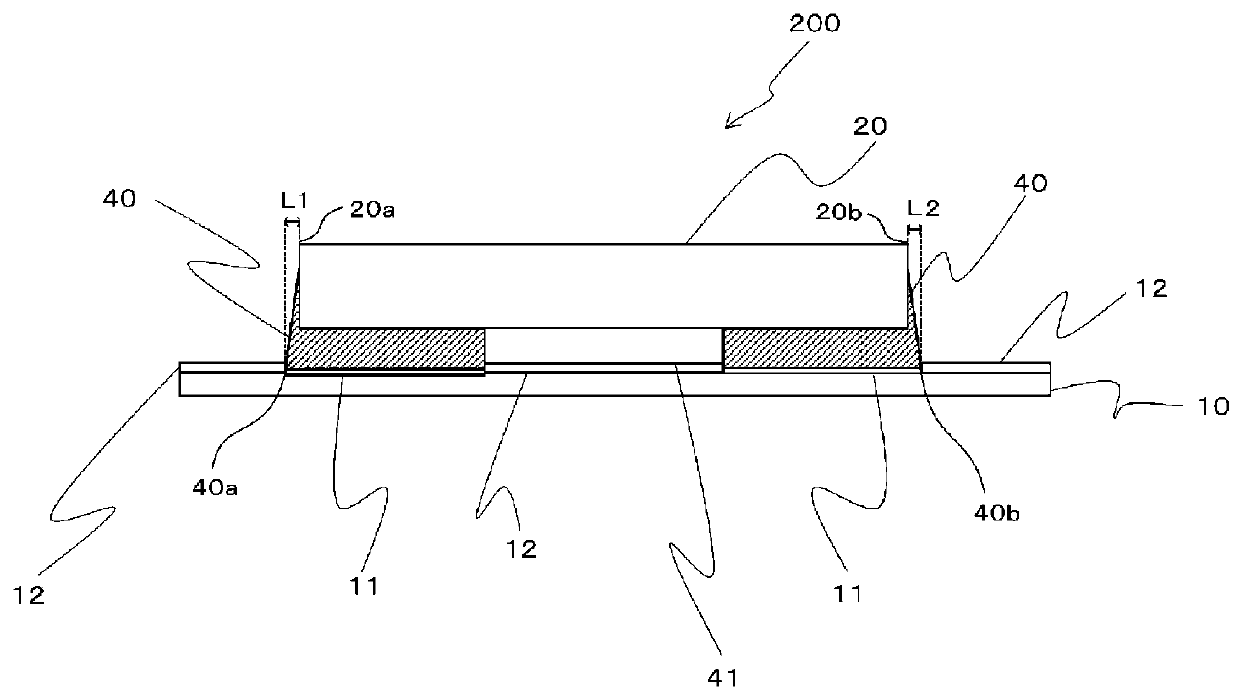

Image

Examples

Embodiment

[0095] Hereinafter, the present invention will be described in detail with reference to Examples and Comparative Examples. In addition, this invention is not limited to these Examples.

[0096] Flux production

[0097] The following components were kneaded to obtain fluxes of Examples and Comparative Examples.

[0098] Hydrogenated acid-modified rosin (product name: KE-604, manufactured by Arakawa Chemical Industry Co., Ltd.) 51% by mass

[0099] Hydrogenated castor oil 6% by mass

[0100] Dodecanedioic acid 10% by mass

[0101] Malonic acid 1% by mass

[0102] Diphenylguanidine hydrobromide 2% by mass

[0103] Hindered phenolic antioxidant (product name: Irganox 245, manufactured by BASF JAPAN Co., Ltd.) 1% by mass

[0104] Diethylene glycol monohexyl ether 29% by mass

[0105] Production of Solder Paste

[0106] Examples 1 to 21 and Comparative Example 1 were prepared by mixing 11% by mass of the aforementioned flux with 89% by mass of the powders (powder particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com