Novel automatic cooker

A cooking machine, a new type of technology, applied to the structure of cooking utensils, plug-ins, heating devices, etc., can solve the problems of inconvenient cleaning, inconvenient feeding and discharging, waste of heating heat, etc., to achieve convenient replacement of parts, The effect of simple and reasonable structure and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

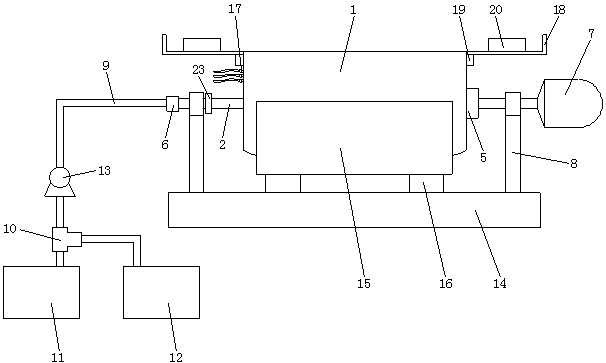

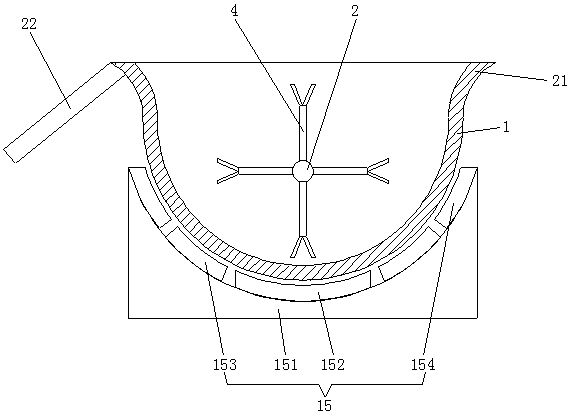

[0029] see Figure 1-4 , a new type of cooking machine, including a pot body 1 and a PLC control system, the cross section of the pot body 1 is an arc structure, the left and right ends of the pot body are closed, the upper end is open, and the stirring shaft 2 of the hollow structure is arranged horizontally in the pot body, and the stirring shaft 2, a number of water spray holes 3 and a number of stirrer shovels 4 are set, the left and right ends of the stirring shaft 2 extend to the outside of the pot body, and a clutch 5 is set at one end, and a universal spray joint 6 is set at the other end. Cooperate with the stir-fry motor 7, the stir-fry motor 7 drives the stirring shaft 2 or the pot body 1 to rotate respectively through the clutch 5, the left and right ends of the stirring shaft 2 are provided with bearing seats 8, and the universal spray joint 6 is connected with a water pipe 9, The water pipe 9 communicates with the fresh water tank 11 and the washing water tank 12...

Embodiment 2

[0039] A new type of cooking machine, including a pot body 1 and a PLC control system. The cross section of the pot body 1 is an arc structure, the left and right ends of the pot body are closed, and the upper end is open. A stirrer shovel 4, the left and right ends of the stirring shaft 2 extend to the outside of the pot body, and one end is provided with a stirrer motor 7, the left and right ends of the stirrer shaft 2 are provided with a bearing seat 8, and the bottom of the bearing seat 8 is provided with the same base 14. The left and right ends of the base 14 are provided with turning shafts 24, and one of the turning shafts is provided with a vegetable output motor 25, and the turning shaft 24 is provided with a bearing column 26. The bottom of the bearing column 26 is provided with the same base 27, and the bottom of the pot body 1 A heater 15 is provided, and the bottom of the heater 15 is fixed on the base 14 by setting a support member 16; the PLC control system is e...

Embodiment 3

[0041] A new type of cooking machine, including a pot body 1 and a PLC control system. The cross section of the pot body 1 is an arc structure, the left and right ends of the pot body are closed, and the upper end is open. A stir-frying shovel 4, one end of the stirring shaft is fixed on the inner wall of the pot body, the other end extends to the outside of the pot body and a stir-frying motor 7 is arranged, and a bearing seat 8 is arranged on the stirring shaft, and a base 14 is arranged at the bottom of the bearing seat 8 The outer end of the pot body 1 away from the stirring shaft is provided with a turning shaft 24, the turning shaft 24 is provided with a vegetable discharge motor 25, and the turning shaft 24 is also provided with a bearing seat 8, and the turning shaft 24 and the stirring shaft 2 are located at the center of the pot body. On the horizontal line, the heater 15 is arranged at the bottom of the pot body 1, and the bottom of the heater 15 is fixed on the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com