Hydrocracking catalyst containing composite Beta molecular sieve as well as preparation method and application of hydrocracking catalyst

A hydrocracking and catalyst technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as long-range order and short-range order of materials that are difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

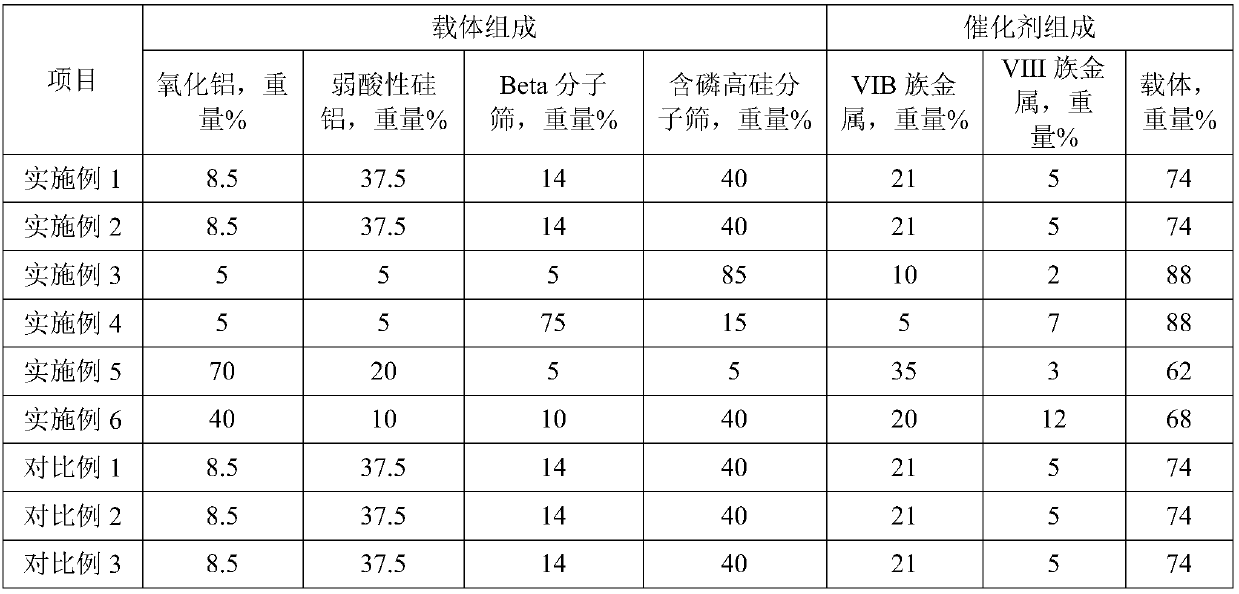

[0065] The preparation method of the carrier is well known to those skilled in the art, and the present disclosure has no special limitation. For example, the method may also include: mixing high-silicon and phosphorus-containing molecular sieves, Beta molecular sieves, weakly acidic silica-alumina and alumina, and then molding and drying to obtain the carrier. The forming method can adopt various conventional methods, such as tablet forming, rolling ball forming or extrusion forming and the like.

[0066] The present disclosure has no special requirements on the shape of the carrier, which can be spherical, strip-shaped, hollow strip-shaped, spherical, block-shaped, etc., and the strip-shaped carrier can be multi-leaf clover-shaped, four-leaf clover-shaped, etc. deformed body.

[0067] According to the present disclosure, the first metal precursor is a soluble compound containing the first metal, including at least one of an inorganic acid of the first metal, an inorganic sa...

preparation Embodiment 1

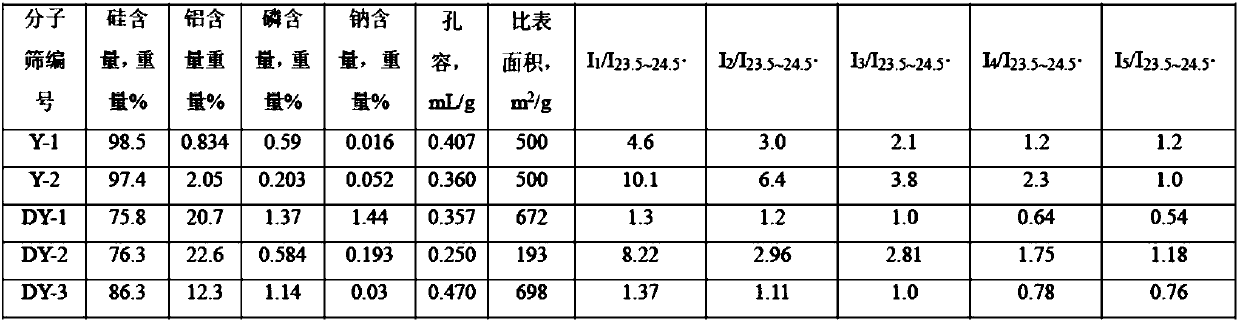

[0082] Get RY molecular sieve (produced by Sinopec Catalyst Changling Branch Company, unit cell constant is 2.456nm, specific surface area is 672m 2 / g, the pore volume is 0.357mL / g, Na 2 O content is 1.44 wt%, P 2 o 5 The content is 1.37% by weight) 500g was put into a hydrothermal kettle, 100% steam was passed through, and the hydrothermal treatment was carried out at 560°C and 0.8MPa for 3 hours, and then the hydrothermally treated molecular sieve material was taken out.

[0083] Take 50 g (dry basis) of the molecular sieve material after hydrothermal treatment obtained above, add 500 mL of deionized water, stir and beat to obtain the first slurry, heat it up to 80 ° C, add 2.0 mol / L sulfuric acid solution, and detect the When the pH value of the first slurry was 2.8, the addition of acid was stopped, then the reaction was carried out at constant temperature for 4 hours, and filtered to obtain 40 g of the first solid product.

[0084] Add the first solid product above to...

preparation Embodiment 2

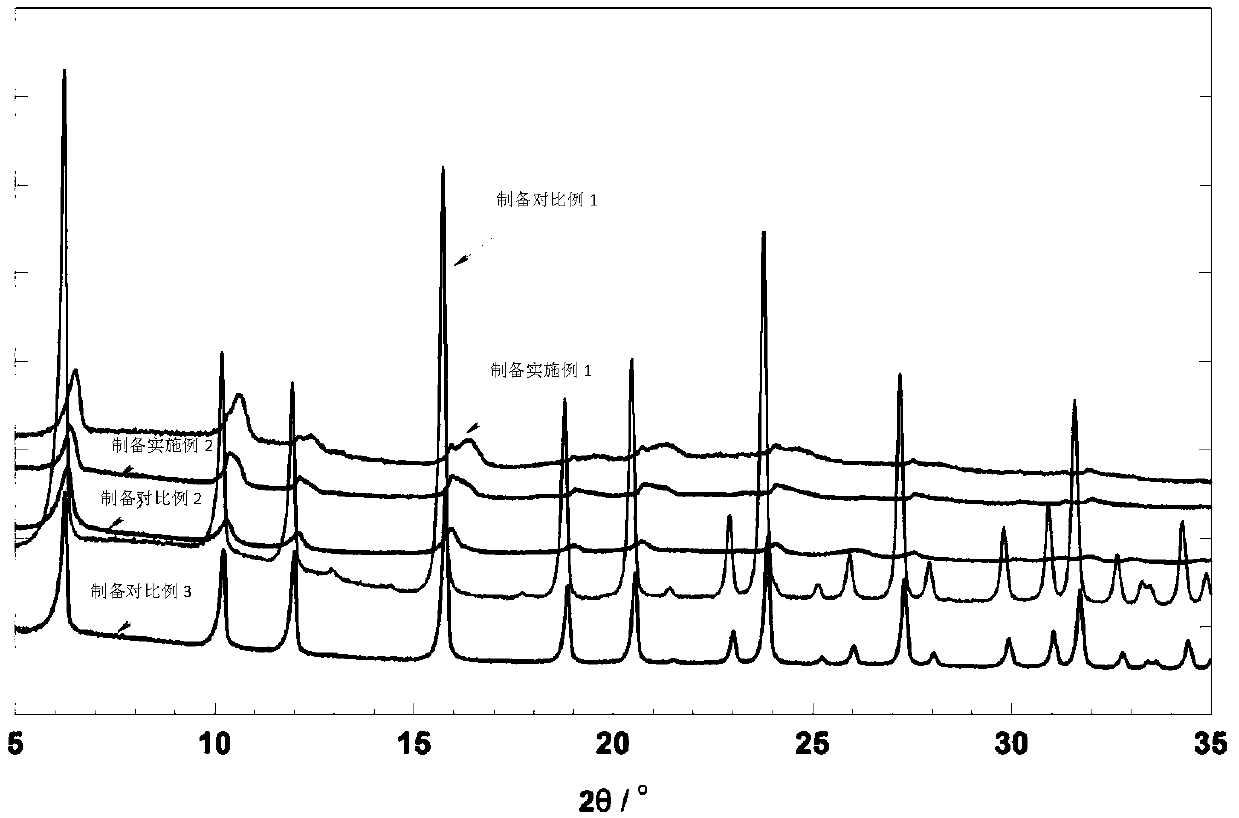

[0086] The molecular sieve with high silicon content was prepared according to the method of Preparation Example 1, with the difference that when adding the second acid solution, it was added at a rate of 15 mol / h. Molecular sieve Y-2 was prepared, and its XRD spectrum is shown in Figure 1. It can be seen that the diffraction angle position of the first strong peak is 6.1-6.8°, the diffraction angle position of the second strong peak is 10.2-10.7°, and the third strong peak The diffraction angle position of the peak is 15.8-16.5°, the diffraction angle position of the fourth strongest peak is 20.8-21.4°, and the diffraction angle position of the fifth strongest peak is 12.1-12.6°. Other properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com