Combined double-track drilling machine and automatic drilling method

A drilling machine and combined technology, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing machinery parts, etc., can solve the problems of hidden safety hazards, low efficiency, difficult hoisting, etc., and achieve reduction Volume, firm fixation, and the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment, the present invention is further described, and following embodiment is illustrative, not restrictive, can not limit protection scope of the present invention with following embodiment.

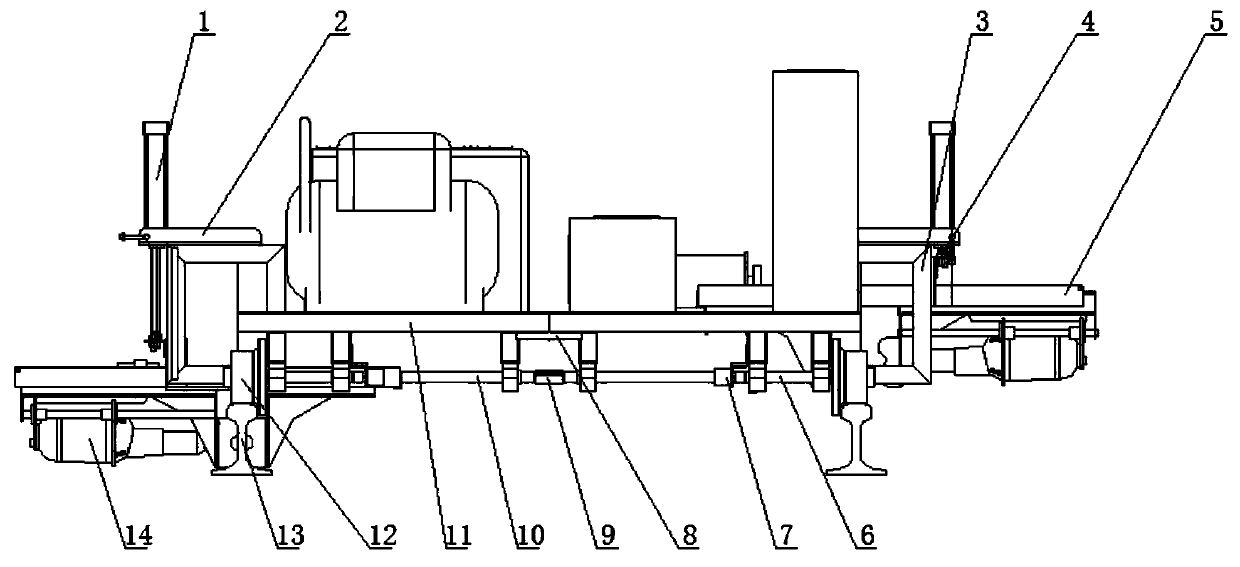

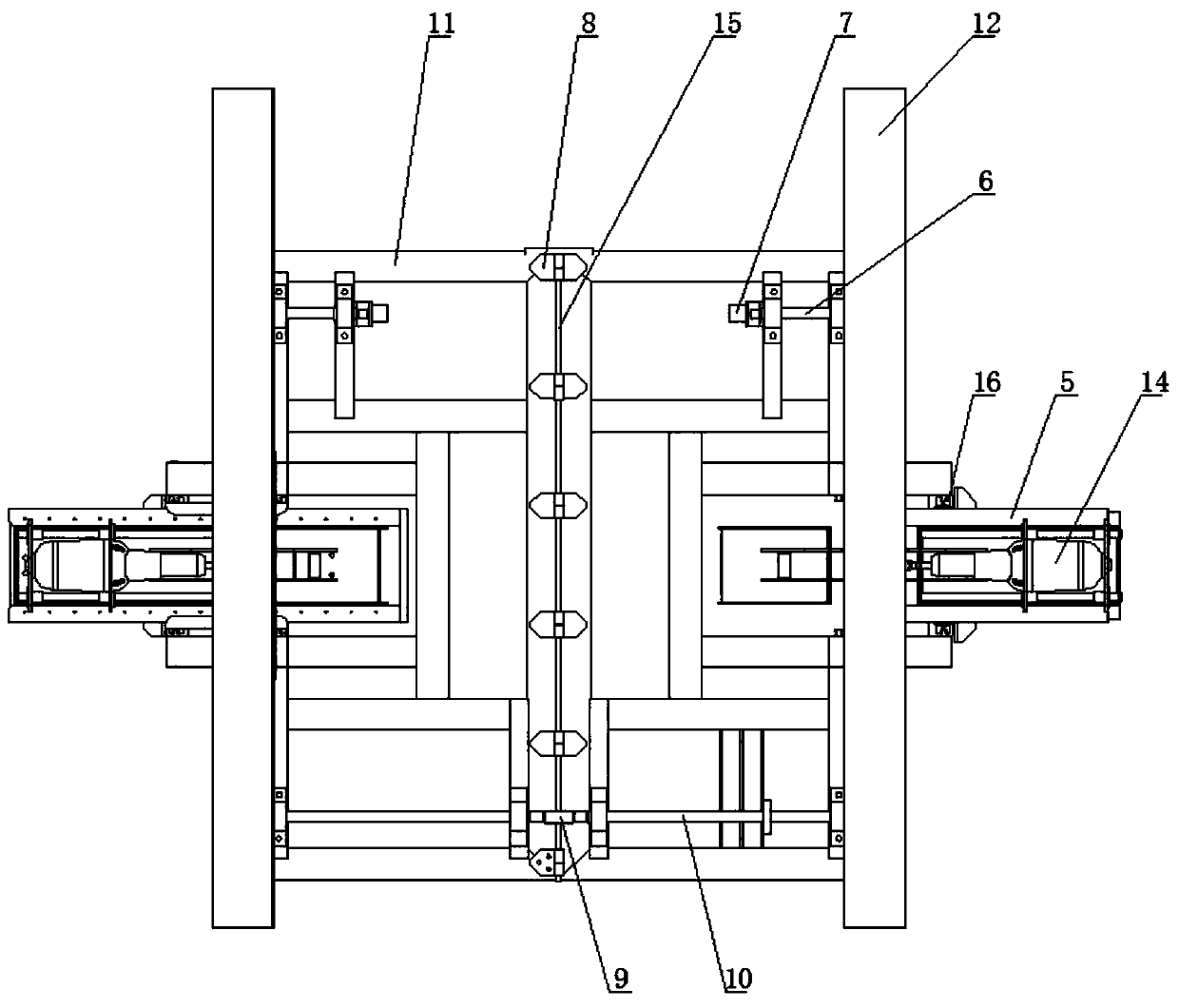

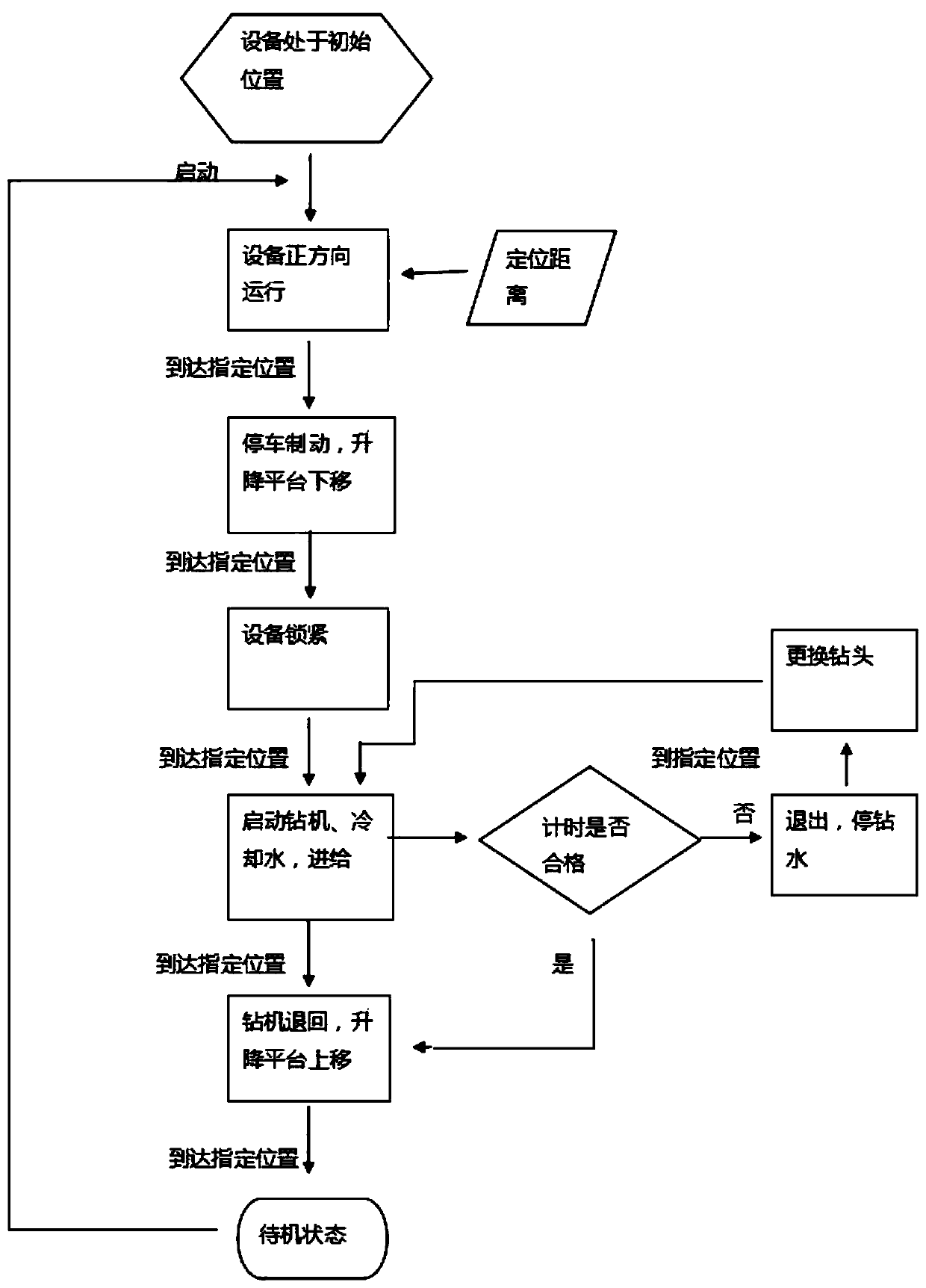

[0029] A combined double-track drilling machine, the innovation of the present invention is that it includes a two-stage splicing platform, and the splicing platform includes two half-platforms 11, and the ends of the two half-platforms on the same side are movable and fixed. A drilling mechanism is respectively installed on the opposite side ends of the two halves, and the two drilling mechanisms are respectively located at the side positions outside the same-side rail.

[0030] In this embodiment, devices such as a stepping motor, a water tank, a generator and a central control box are installed in the upper end surface of the splicing platform.

[0031] In this embodiment, the ends of the two halves on the same side are respectively equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com