Ceramsite refractory material based on mud recycling soil and preparation method thereof

A refractory material and resource utilization technology, applied in the field of mud resource utilization, can solve the problems of consuming large and high-quality soil, destroying the ecological environment, etc., and achieve high social and economic value, the unity of ecological and economic benefits, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

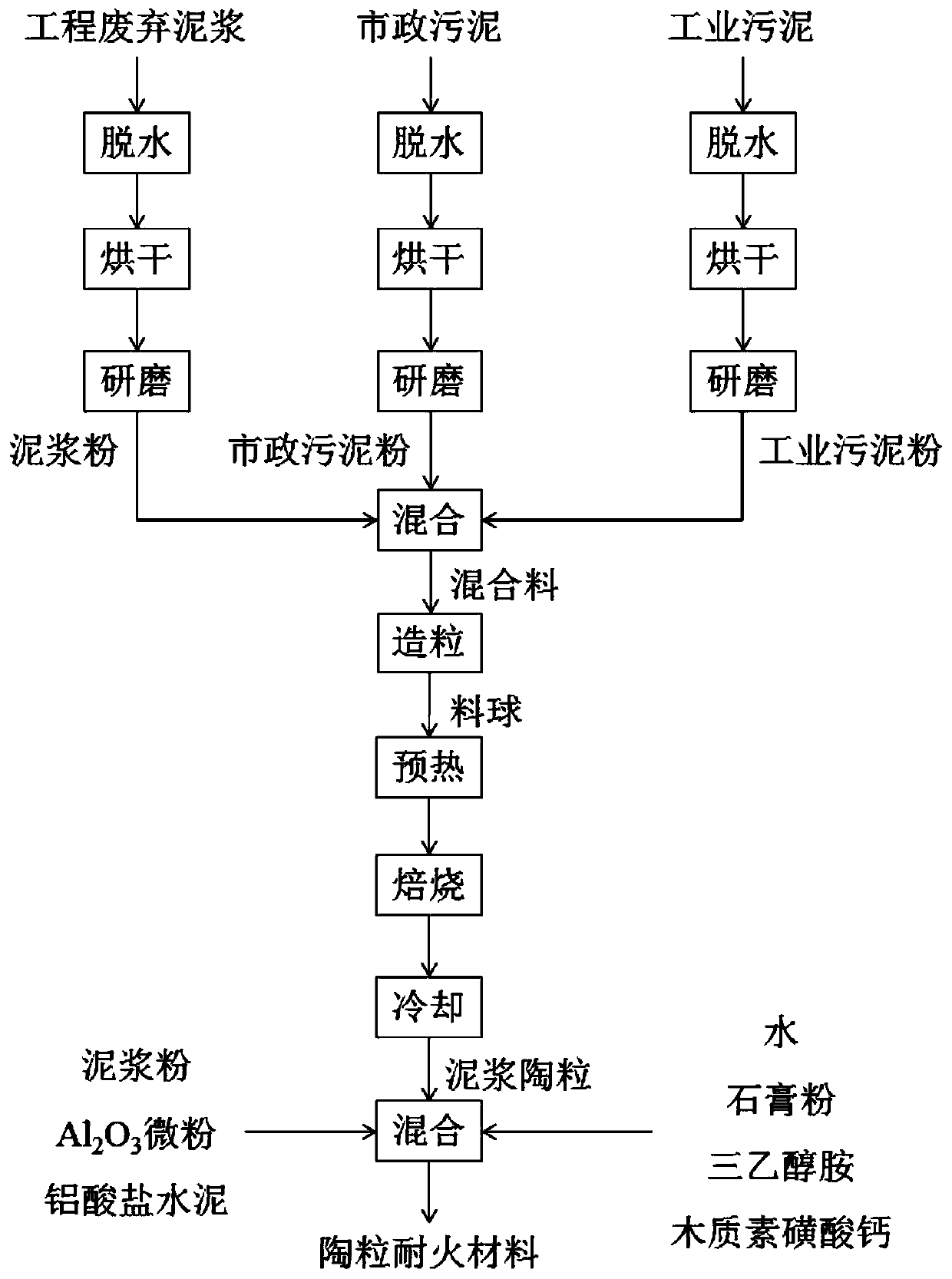

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, a ceramsite refractory material based on mud resource soil, including the following components and weight percentages: 50% mud ceramsite, 25% mud powder, Al 2 o 3 Micropowder 3%, aluminate cement 10%, water 11.5%, gypsum powder 0.2%, triethanolamine 0.25%, calcium lignosulfonate 0.05%.

[0036] Wherein, the mud ceramsite includes the following components and weight percentages: mud powder 80%, municipal sludge powder 10% and industrial sludge powder 10%.

[0037] The ceramsite refractory material in the present embodiment is prepared according to the following method:

[0038] 1) Put the mud powder, municipal sludge powder and industrial sludge powder in the mixing bin in proportion, and stir for 8 minutes to make it evenly mixed to obtain the mixture;

[0039] 2) Place the mixture in step 1) in a granulator, spray into atomized water, and then run the granulator for 40 minutes to obtain pellets with a particle size of 0.5-15 mm;

[0040] 3) Preheat...

Embodiment 2

[0043] In this embodiment, a ceramsite refractory material based on mud resource-resourced soil includes the following components and weight percentages: 50% mud ceramsite, 30% mud powder, 5% aluminate cement, 14% water, 0.5% gypsum powder, 0.5% triethanolamine.

[0044] Wherein, the mud ceramsite includes the following components and weight percentages: mud powder 80%, municipal sludge powder 10% and industrial sludge powder 10%.

[0045] The ceramsite refractory material in the present embodiment is prepared according to the following method:

[0046] 1) Put the mud powder, municipal sludge powder and industrial sludge powder in the mixing bin in proportion, and stir for 8 minutes to make them evenly mixed;

[0047] 2) Put the mixed material in step 1) into the granulator to granulate, and spray atomized water into the granulator when the granulator is started for 10 minutes, and then the granulator continues to run for 40 minutes to obtain a material with a particle size o...

Embodiment 3

[0051] In this embodiment, a kind of ceramsite refractory material based on mud resource-resourced soil includes the following components and weight percentages: 57.5% of mud ceramsite, 20% of mud powder, Al 2 o 3 Micropowder 2.5%, aluminate cement 7.5%, water 11.5%, gypsum powder 0.5%, triethanolamine 0.48%, calcium lignosulfonate 0.02%.

[0052] Wherein, the mud ceramsite includes the following components and weight percentages: mud powder 80%, municipal sludge powder 10% and industrial sludge powder 10%.

[0053] The ceramsite refractory material in the present embodiment is prepared according to the following method:

[0054] 1) Put the mud powder, municipal sludge powder and industrial sludge powder in the mixing bin in proportion, and stir for 8 minutes to make them evenly mixed;

[0055] 2) Put the mixed material in step 1) into the granulator to granulate, and spray atomized water into the granulator when the granulator is started for 10 minutes, and then the granula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com