Anti-adhesion medical antibacterial PVC material

A PVC material and anti-adhesion technology, applied in the field of medical film material production, can solve problems such as adhesion, achieve the effects of preventing adhesion, preventing secondary pollution, and optimizing the damp heat sterilization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

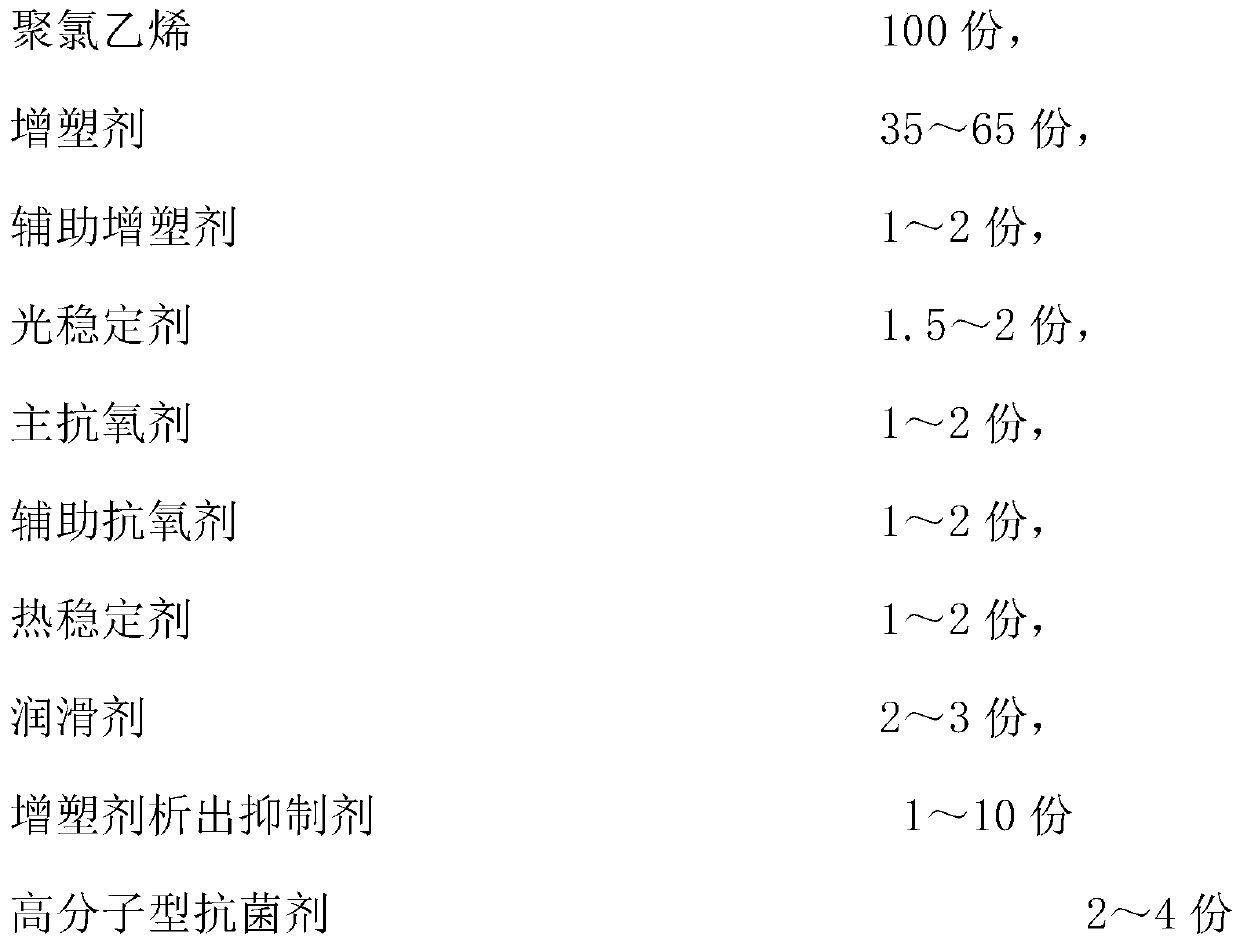

[0050]

[0051]

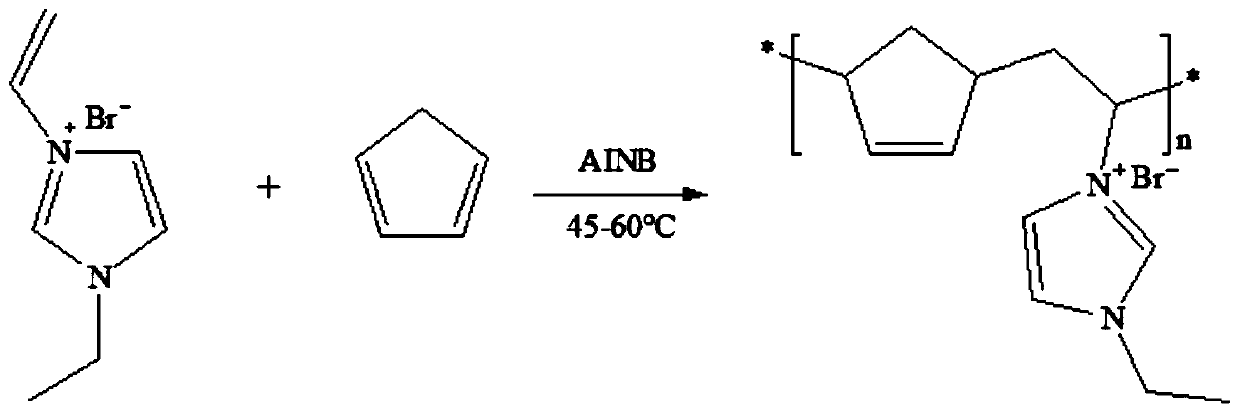

[0052] The preparation method of macromolecular type antibacterial agent, its specific steps are: take 1-vinyl-3-ethyl imidazolium bromide and cyclopentadiene as raw materials, azobisisobutyronitrile (AIBN) as initiator, in the reaction The temperature is 45-60°C, the raw materials and the initiator are mixed evenly, and then reacted under nitrogen protection, the reaction time is controlled to be 4-6 hours, so that the conversion rate of the monomer is more than 96%, and the polymer antibacterial agent is prepared. The molar ratio of 1-vinyl-3-ethylimidazolium bromide to cyclopentadiene is 1:1, and the initiator is controlled at 0.3wt% of the total mass of the two raw materials.

[0053]Due to its non-polar structure, PVC itself does not contain polar groups in its molecular structure. It is difficult to disperse functional components such as antibacterial agents in the resin matrix, which makes it difficult to add functional additives such as powder in...

Embodiment 2

[0056]

[0057]

[0058] The preparation method of macromolecule type antibacterial agent is with embodiment 1.

[0059] A kind of preparation method of anti-adhesion medical antibacterial PVC material is the same as embodiment 1.

Embodiment 3

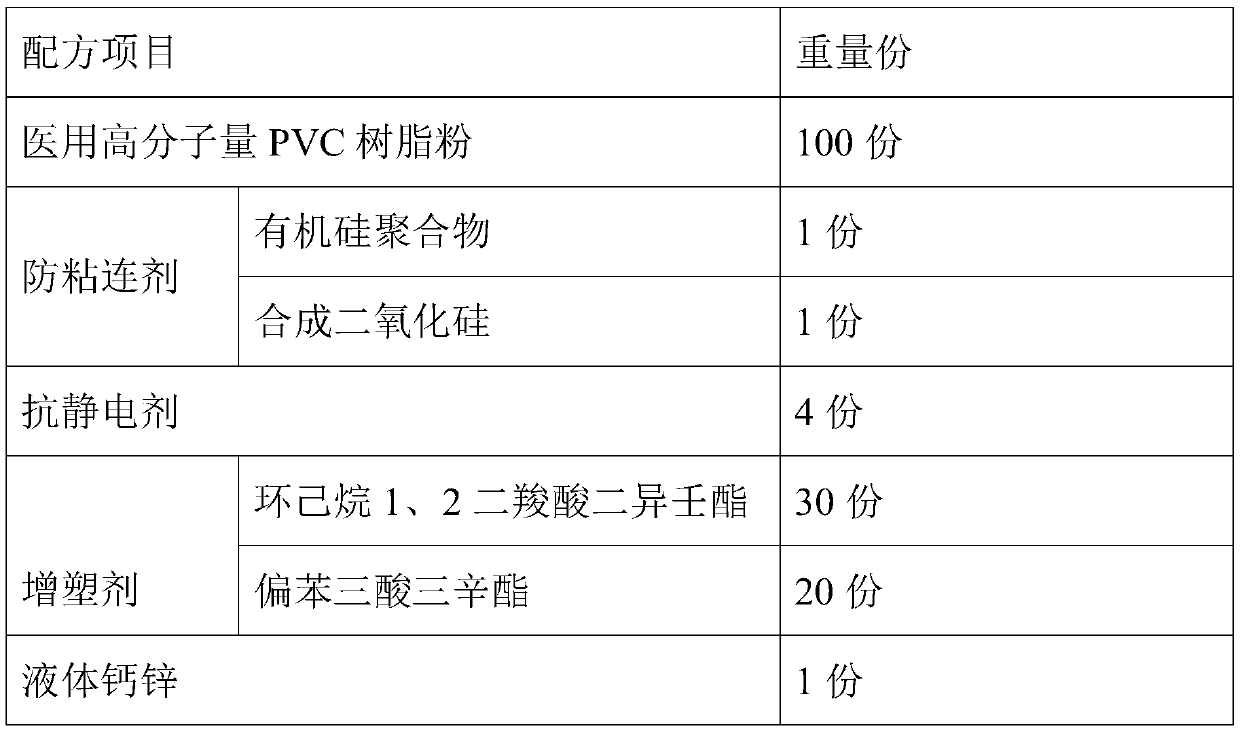

[0065] The present application also provides a radiation-resistant sterilization medical polyvinyl chloride material, the raw material components are:

[0066]

[0067]

[0068] The preparation of macromolecular type antibacterial agent is the same as embodiment 1.

[0069] The preparation method of the radiation-resistant sterilization medical polyvinyl chloride material comprises the following steps:

[0070] 1. After heating and stirring at 20-40rpm to 80-90°C, add light stabilizer, main antioxidant, auxiliary antioxidant, heat stabilizer, run at 400-600rpm, and add lubricant when the temperature reaches 120-125°C agent and plasticizer precipitation inhibitor;

[0071] Continue to stir until 140-150°C and discharge to the cooling mixer at a speed of 30-45rpm. When the temperature of the material is cooled to 45-60°C, the material is discharged;

[0072] 2. Use a twin-screw extruder to granulate the material obtained in step 1. The material is plasticized by the ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com