A low-temperature composite phase-change energy storage material, its preparation method and application

An energy storage material and composite phase change technology, applied in the field of phase change materials, can solve problems such as difficulty in ensuring stability and easy damage of inorganic shell materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

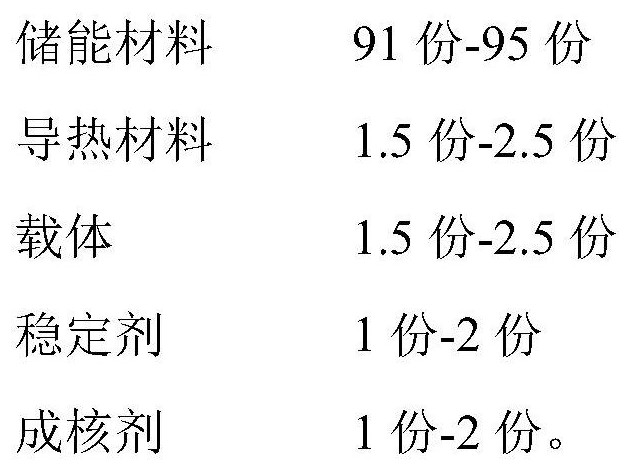

Method used

Image

Examples

Embodiment 1

[0057] The preparation of embodiment 1 hexamethylenediamine@polystyrene-divinylbenzene microcapsules

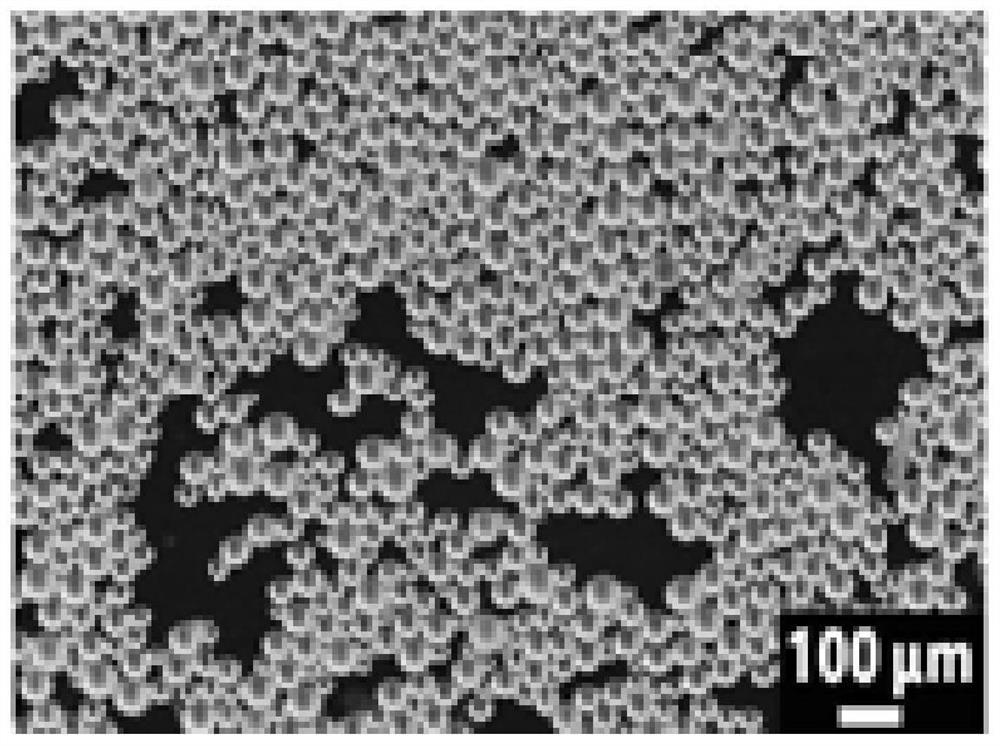

[0058] Dissolve 25g of hexamethylenediamine in 100mL of water, add 2g of Span 80, keep the temperature at 80°C, stir at 1000r / min for 30min, and prepare 50mL of toluene to dissolve 4g of styrene and 4g of divinylbenzene. After the emulsification is complete, add In the system, dissolve 0.5g of sodium persulfate in 10g of water and add, after reacting for 6 hours, let stand, filter, and dry to obtain microcapsule powder. Gained microcapsule powder SEM photograph is as figure 1 shown.

Embodiment 2

[0059] The preparation of embodiment 2 octyldiamine@polystyrene-divinylbenzene microcapsules

[0060] Dissolve 25g of octanediamine in 100mL of water, add 2g of Span 80, keep the temperature at 80°C, stir at 1000r / min for 30min, prepare 50mL of toluene to dissolve 4g of styrene and 4g of divinylbenzene, add In the system, dissolve 0.5g of sodium persulfate in 10g of water and add, after reacting for 6 hours, let stand, filter, and dry to obtain microcapsule powder. Gained microcapsule powder SEM photograph is as figure 1 shown.

Embodiment 3

[0061] Embodiment 3 Preparation of decanediamine@polystyrene-divinylbenzene microcapsules

[0062] Dissolve 25g of decanediamine in 100mL of water, add 2g of Span 80, keep the temperature at 80°C, stir at 1000r / min for 30min, prepare 50mL of toluene to dissolve 4g of styrene and 4g of divinylbenzene, and add In the system, dissolve 0.5g of sodium persulfate in 10g of water and add, after reacting for 6 hours, let stand, filter, and dry to obtain microcapsule powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com