Mineralization degree sensitive diversion temporary plugging agent and preparation method and application thereof

A technology of salinity and temporary plugging agent, used in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of poor diversion effect and cumbersome construction process, so as to promote the diversion of acid solution and improve The effect of the water absorption profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A salinity-sensitive shunting temporary plugging agent, comprising olefin sulfonic acid, sodium octyl sulfate, sodium lauryl sulfate, methanol and water; the mass percentages of each component are: olefin sulfonic acid is 20.0%-25.0% %, sodium octyl sulfate is 10.0%-20.0%, sodium lauryl sulfate is 3.0%-5.0%, methanol is 20.0%-25.0%, and the balance is water.

[0035] In actual use, the mass percent of olefin sulfonic acid used in the present invention is 20.0%-25.0%, so that when the calcium ion concentration produced in the acid liquid and formation reaction process is raised to more than 2.0%, the olefin sulfonic acid and calcium ion can Form micelles of 5-50 microns, and form bridging ions in the percolation channel to play a role in bridging. The mass percentage of sodium octyl sulfate is 10.0%-20.0%, so that when the concentration of calcium ions generated during the reaction between the acid liquid and the formation rises to more than 3%, sodium octyl sulfate and ...

Embodiment 2

[0046] A salinity-sensitive shunt temporary plugging agent, the difference from Example 1 is that the mass percentages of the olefin sulfonic acid, octyl sodium sulfate, lauryl sodium sulfate, methanol and water are: olefin 20.0% of sulfonic acid, 10.0% of sodium octyl sulfate, 3.0% of sodium lauryl sulfate, 20.0% of methanol, and the balance is water.

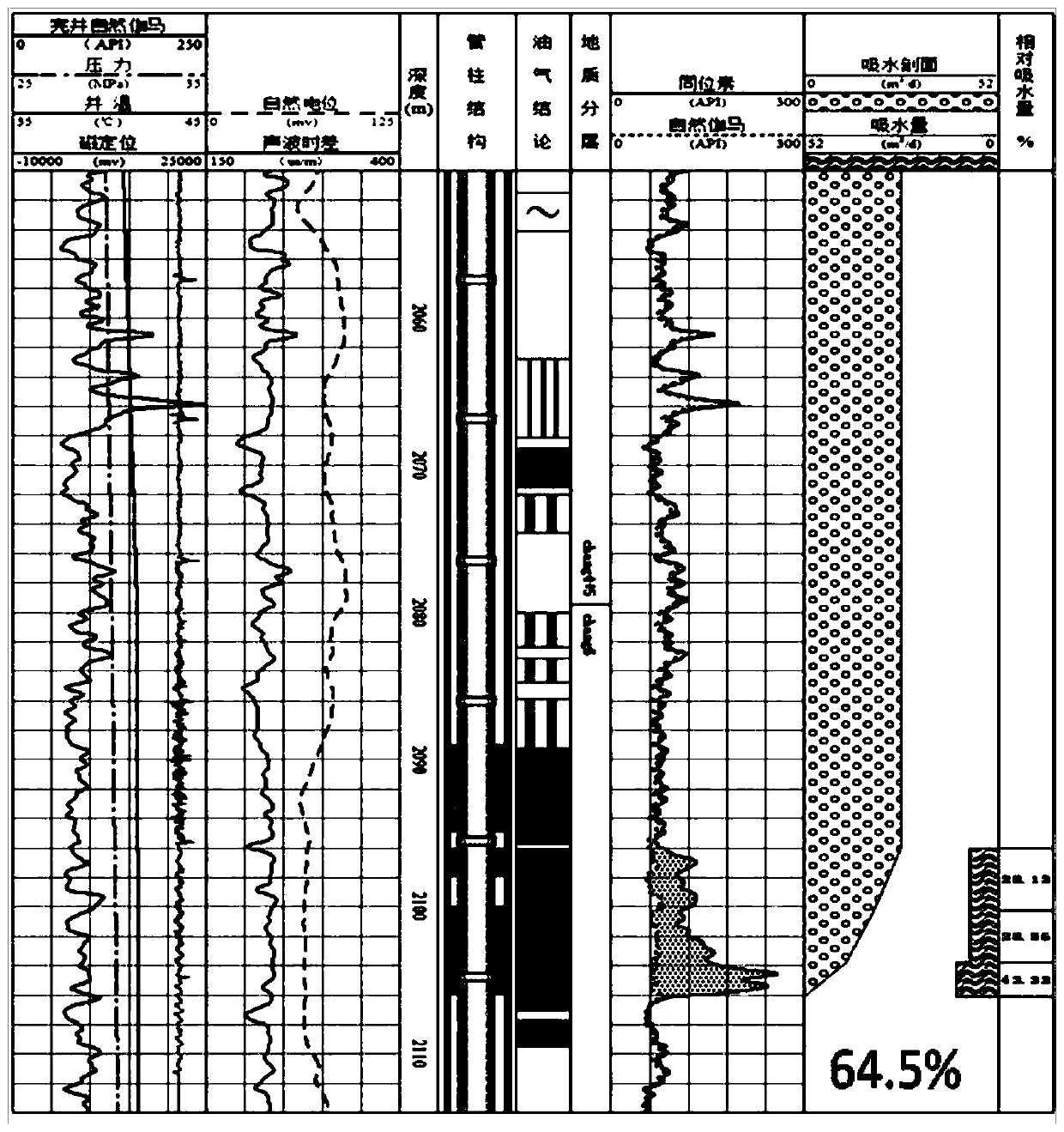

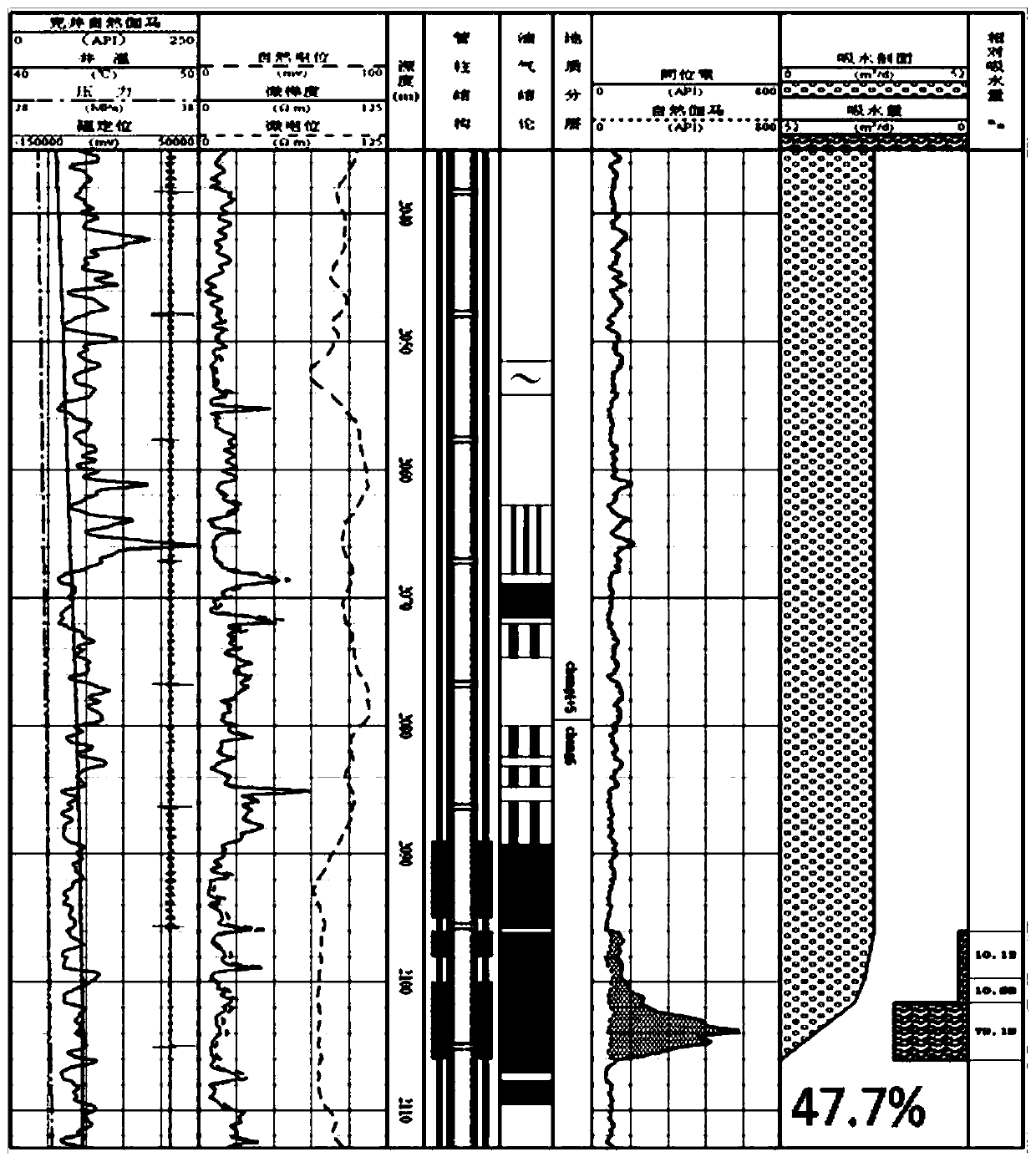

[0047] The salinity-sensitive shunt temporary plugging agent prepared according to the above composition ratio was first field tested in an oilfield. The test well is a water well, and the water absorption profile shows that the upper layer absorbs 82% of water and the lower layer absorbs 18%. In order to further adjust the water absorption profile and improve the degree of water driving, a technical test on the adjustment of the mineralization degree control profile was carried out.

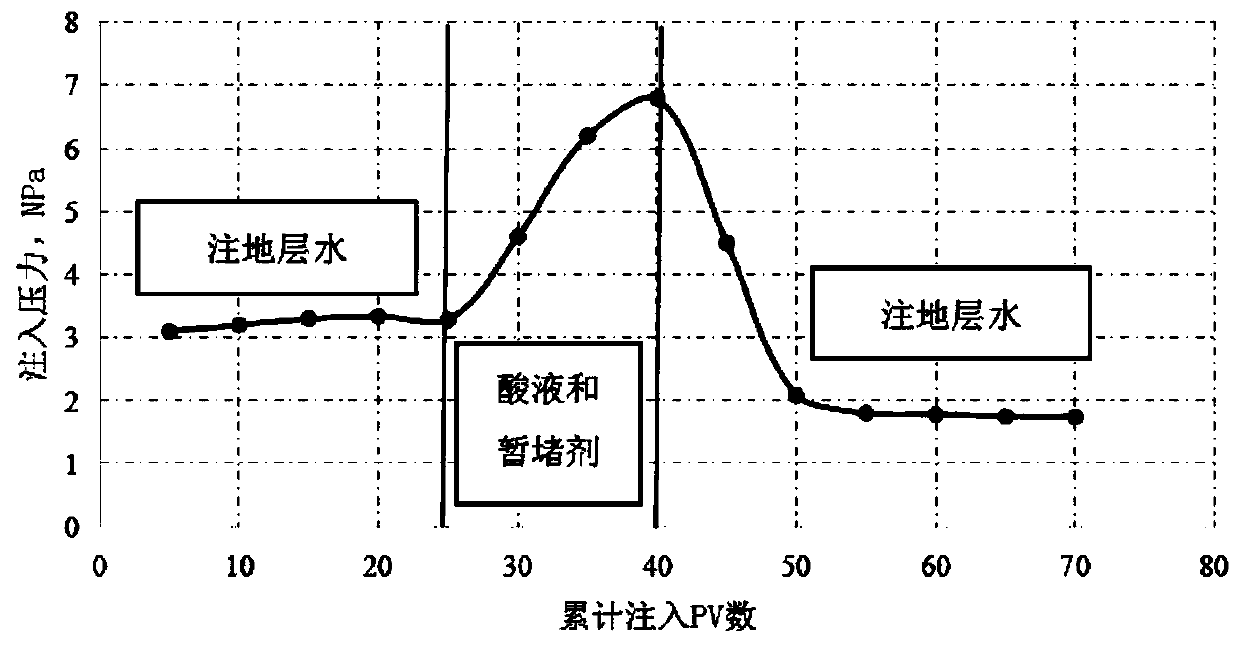

[0048] The salinity-sensitive shunting temporary plugging agent of the present invention is added to the acid liquid at a concentration of 1.5% ...

Embodiment 3

[0053] A salinity-sensitive shunt temporary plugging agent, the difference from Example 1 is that the mass percentages of the olefin sulfonic acid, octyl sodium sulfate, lauryl sodium sulfate, methanol and water are: olefin 25.0% of sulfonic acid, 20.0% of sodium octyl sulfate, 5.0% of sodium lauryl sulfate, 25.0% of methanol, and the balance is water.

[0054] The salinity-sensitive shunt temporary plugging agent prepared according to the above composition ratio was first field tested in an oilfield. The test well is a water well, and the water absorption profile shows that the upper layer absorbs 93% of water and the lower layer absorbs 7%. In order to further adjust the water absorption profile and improve the degree of water driving, a technical test on the adjustment of the mineralization degree control profile was carried out.

[0055] The acid control diversion agent of the present invention is added to the acid solution, and the concentration is 3.0% of the volume of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com