Lubricating grease composition and preparation method thereof

The technology of a grease composition and thiadiazole derivatives, which is applied in the field of grease composition and its preparation, can solve the problems of decreased anti-wear performance, inability to meet the anti-wear durability of grease, difficulty in maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

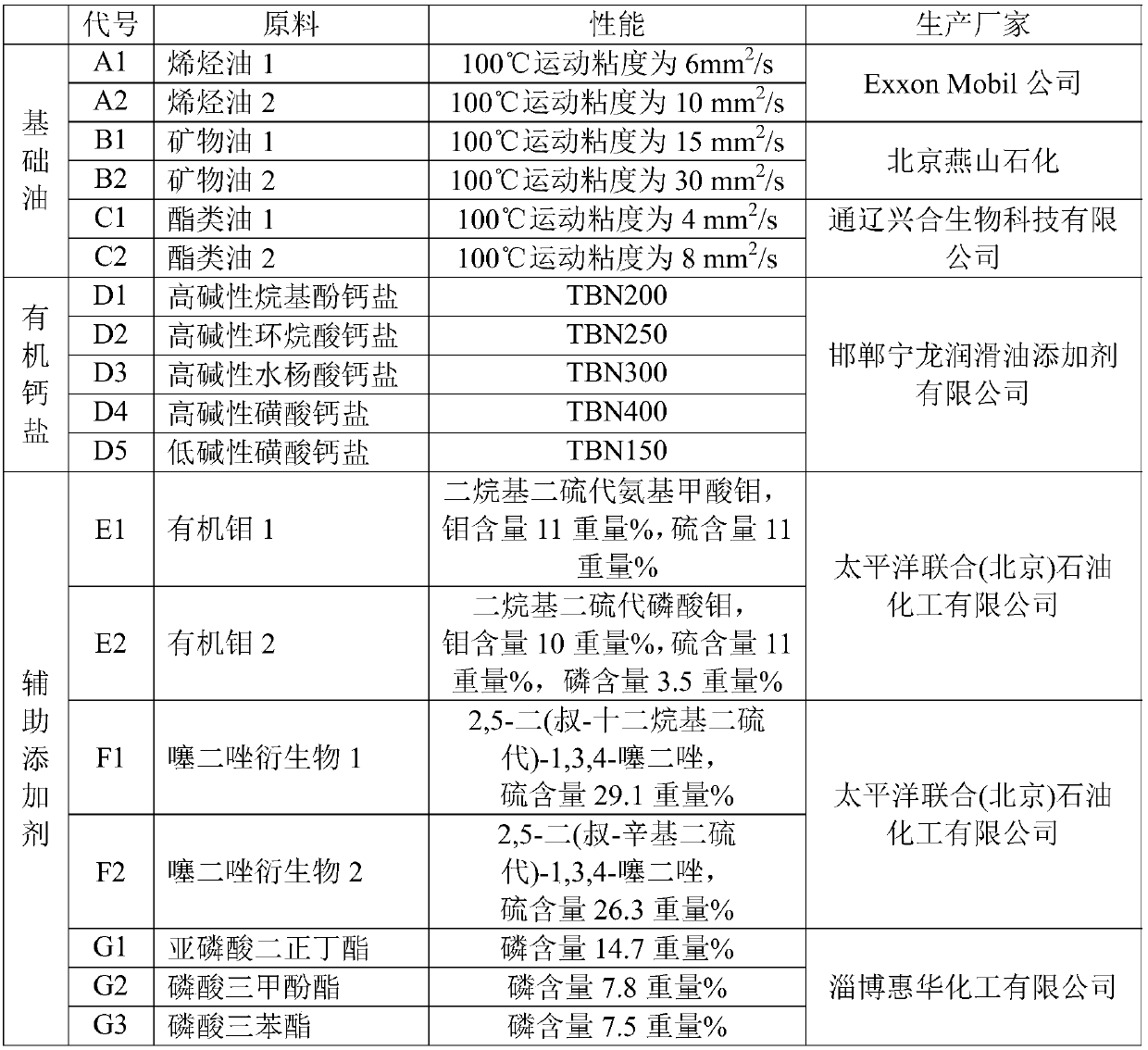

Embodiment 1-12 and comparative example 1-14

[0036] According to the proportions shown in Table 2-4 (the weight ratio based on the total weight of the grease composition), add about 1 / 3 of the base oil and thickener in the reaction kettle, heat up, and gradually add about 1 / 3 3 base oil, the temperature rises to 205°C, add the remaining base oil, cool down the material, when the temperature drops to 105°C, gradually add organic calcium salt and auxiliary additives, the material is ground by a three-wheel mill to make the material evenly dispersed, Samples of grease compositions were prepared.

[0037] According to the following methods, the obtained grease composition sample is analyzed for physical and chemical properties:

[0038] Cone penetration (0.1mm, 60 times): GB / T 269-1991, the smaller the cone penetration of 60 times, the stronger the thickening ability;

[0039] Dropping point: GB / T 3498-2008, the higher the dropping point, the better the high temperature performance;

[0040] Anti-wear performance: SH / T 020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com