An oxidation-resistant long-life zinc-free hydraulic fluid composition and its preparation method

A long-life, composition-based technology, applied in the field of lubricating oil, can solve problems such as corrosion, and achieve the effects of long oxidation life, excellent oxidation resistance, and excellent oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

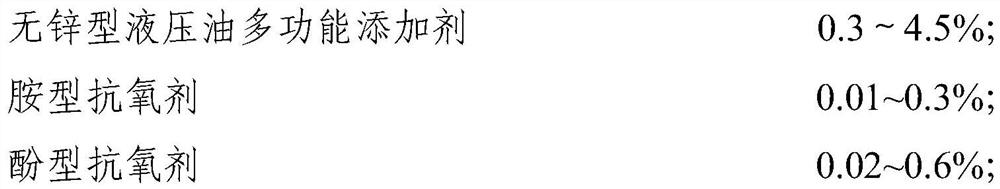

[0061] This embodiment relates to an oxidation-resistant long-life zinc-free hydraulic fluid composition, including the following components:

[0062]

[0063] The preparation method of the above-mentioned hydraulic fluid composition is that various additives are sequentially added into the base oil composition, and stirred at 60° C. for 2 hours to obtain.

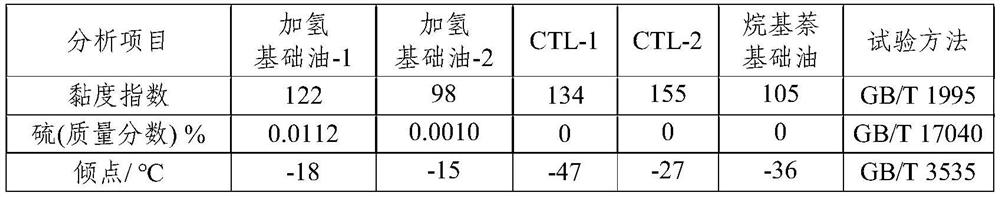

[0064] Take 69.379Kg hydrogenated base oil-1 and 30Kg alkyl naphthalene base oil respectively to form the base oil composition. Take zinc-free hydraulic oil multifunctional additive ( 544) 0.3Kg, amine antioxidant (T557) 0.1Kg, phenolic antioxidant (L118) 0.2Kg, metal deactivator (thiadiazole derivatives) 0.01Kg, pour point depressant (polymethacrylate ) 0.01Kg, anti-foaming agent (simethicone) 0.001Kg, sequentially added to the base oil composition, stirred at 60 ° C for 2 hours, and made into the product of the present invention.

Embodiment 2

[0066] This embodiment relates to an oxidation-resistant long-life zinc-free hydraulic fluid composition, including the following components:

[0067]

[0068]

[0069] The preparation method of the above-mentioned hydraulic fluid composition is that various additives are sequentially added to the base oil composition, and stirred at 60° C. for 2.5 hours to obtain.

Embodiment 3

[0071] This embodiment relates to an oxidation-resistant long-life zinc-free hydraulic fluid composition, including the following components:

[0072]

[0073] The preparation method of the above-mentioned hydraulic fluid composition is that various additives are sequentially added to the base oil composition, and stirred at 55° C. for 2 hours to prepare the product of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com