Low-defect and high-strength polyacrylonitrile carbon fiber and preparation method thereof

A polyacrylonitrile carbon fiber, polyacrylonitrile technology, applied in the chemical characteristics of fibers, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve the problem of low regularity of acrylonitrile sequence, comonomer reactivity Large differences, uneven distribution of copolymerization units, etc., to achieve the effect of good molecular composition consistency, high chain regularity, and uniform distribution of copolymerization units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] 1) Preparation of polyacrylonitrile solution

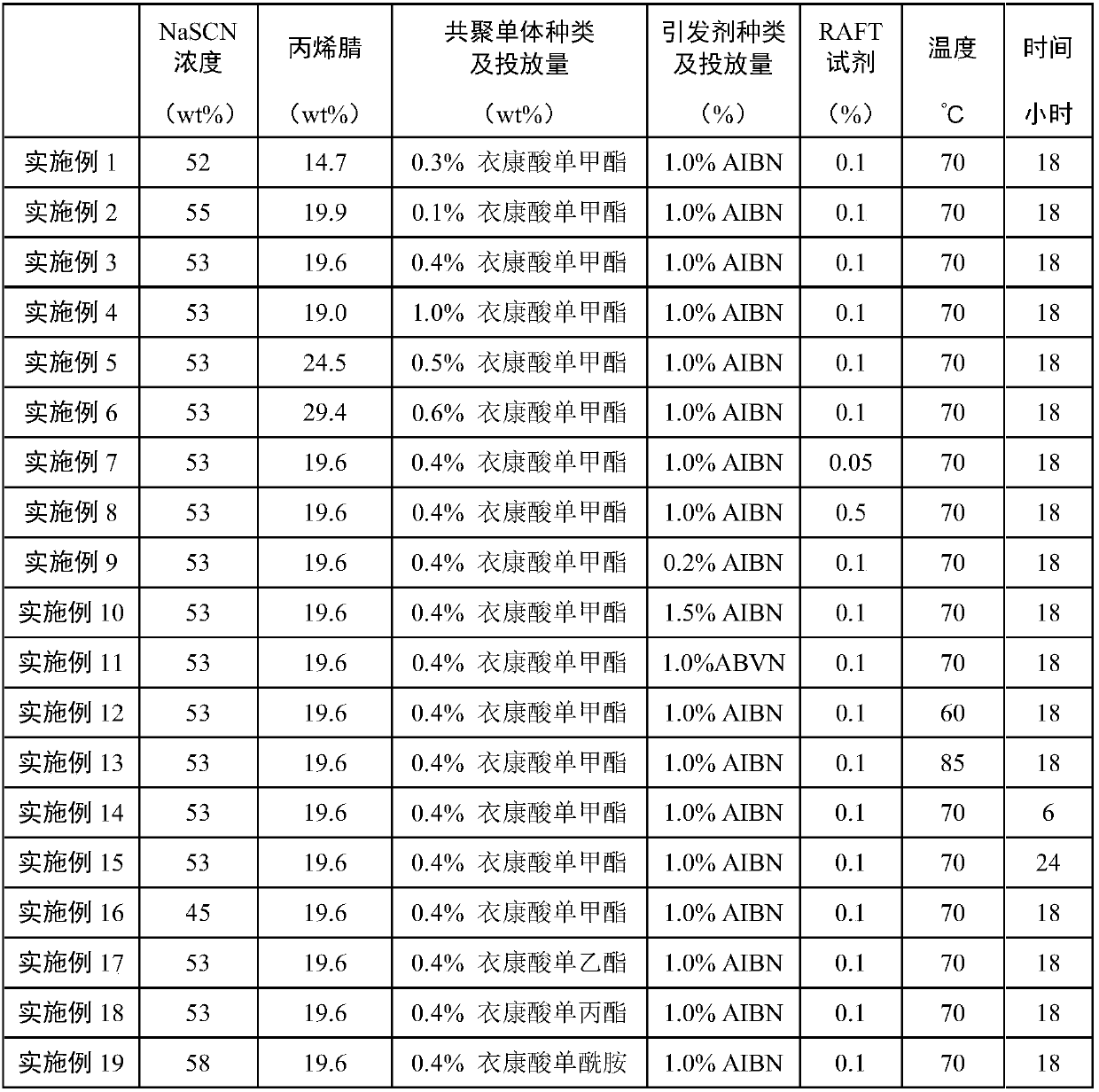

[0032] The polyacrylonitrile solution was prepared according to the polymerization conditions shown in Table 1.

Embodiment 1~19

[0034] Using a certain mass fraction of sodium thiocyanate (NaSCN) aqueous solution as the reaction solvent, azobisisobutyronitrile (AIBN) or azobisisoheptanonitrile (ABVN) as the initiator, S,S'-bis(α,α '-Dimethyl-α"-acetic acid) trithiocarbonate (TRIT) is the RAFT reagent, and acrylonitrile, comonomer, initiator, RAFT reagent and solvent are added to the reactor, and nitrogen gas is introduced to remove oxygen Processing. Then carry out RAFT controllable free radical polymerization under 60~85 ℃, reaction time 6~24 hours.Based on the weight of the whole polymerization system, acrylonitrile dosage is shown in Table 1; The dosage of comonomer, initiator and RAFT reagent are shown in Table 1; the concentration of NaSCN is shown in Table 1; the reaction temperature is shown in Table 1; the reaction time is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com