Polyacrylonitrile resin with controllable molecular weight and distribution and high regularity, and preparation method thereof

A technology of polyacrylonitrile resin and polyacrylonitrile, applied in the field of polyacrylonitrile resin with controllable molecular weight and distribution, high regularity and its preparation, which can solve the problem of limited space for improving carbon fiber performance, uncertain copolymer sequence structure, The free radical copolymerization process is complicated, etc., to achieve good hydrophilicity and pre-oxidation cyclization reaction activity, which is beneficial to the control of molecular weight and its distribution, and the effect of less molecular structure defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

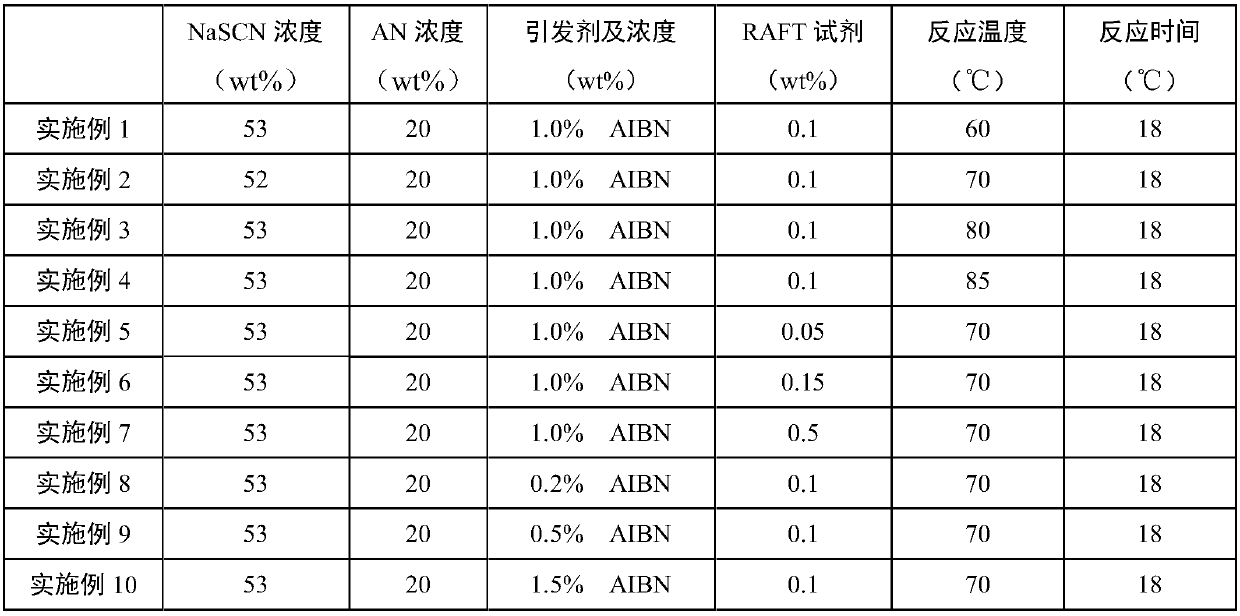

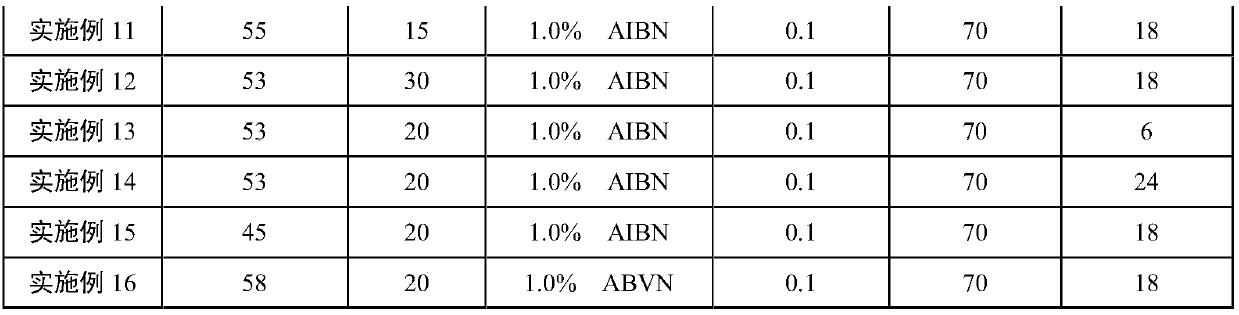

[0019] Using a certain mass fraction of sodium thiocyanate (NaSCN) aqueous solution as the solvent, azobisisobutyronitrile (AIBN) as the initiator, S,S'-bis(α,α'-dimethyl-α″-acetic acid) Trithiocarbonate (TRIT) is a RAFT reagent. The material composed of acrylonitrile monomer, initiator, RAFT reagent and solvent is added to the reactor, nitrogen gas is passed through for oxygen removal treatment, and then RAFT is carried out at a certain reaction temperature. Polymerization, reaction time 6~24 hours.With the weight of whole polymerization system as a basis, the concentration of acrylonitrile monomer is shown in Table 1; Taking monomer weight as a basis, initiator dosage and RAFT dosage are shown in Table 1 Polymerization temperature, polymerization reaction The time is shown in Table 1. Finally, the residual monomer and air bubbles are removed to obtain polyacrylonitrile resin.

[0020] Table 1

[0021]

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com