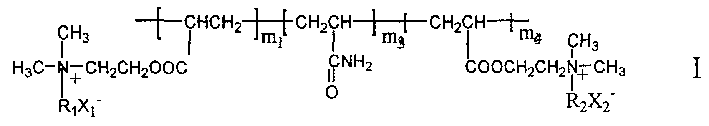

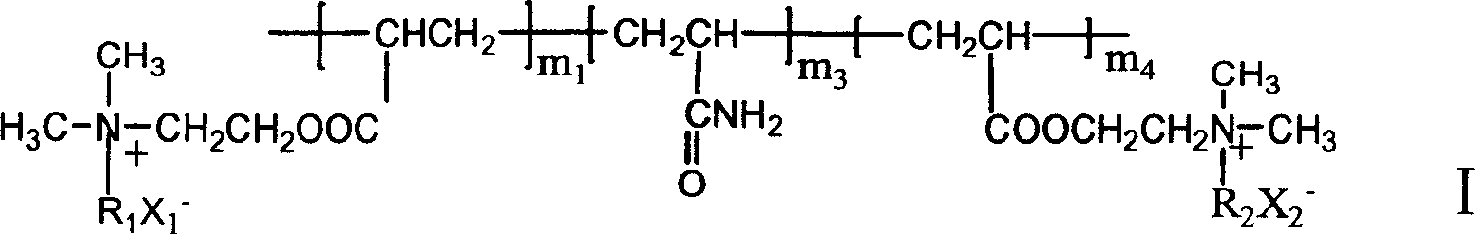

High-performance cation type high-molecular flocculant and preparation method thereof

A polymer flocculant, cationic technology, applied in the field of cationic polymer flocculants and preparation, can solve the problems of long storage period, low emulsion stability, affecting flocculation effect, etc., to reduce secondary pollution, The effect of reducing dosage and excellent flocculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

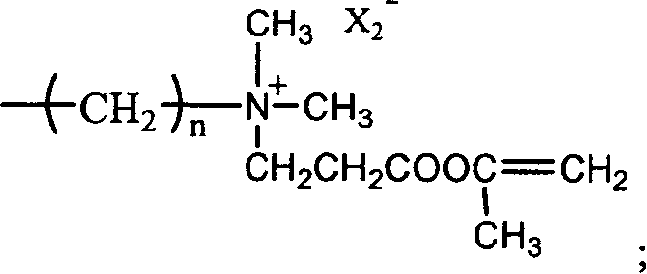

Embodiment 1

[0044] (1) Add 15 parts of dimethylaminoethyl methacrylate, 20 parts of 1-bromohexane, 10 parts of propionitrile to a 50ml round-bottomed flask, control the temperature at 45°C, react for 12 hours, wash with ether, wash with acetone and Co-solvent recrystallization of water to obtain compound (methacryloyloxyethyl dimethyl hexaalkylammonium bromide) B 1 .

[0045] (2) In a 50ml round bottom flask, add 10 parts of distilled water and 10 parts of B 1 , completely dissolved, pass N 2 Add 0.0290 parts of trithiocarbonate in 15 minutes, raise the temperature to 60°C to initiate the reaction, and react for 20 hours. Precipitate with acetone to get macromolecular emulsifier A 1 The crude product is recrystallized with a mixed solvent of acetone and water to obtain macromolecular emulsifier A 1 , vacuum dried.

[0046] (3) Add 15 parts of dimethylaminoethyl methacrylate, 8.5 parts of 1,4-dibromobutane, and 10 parts of propionitrile to a 50ml round-bottom flask, control the temper...

Embodiment 2

[0049] In a 250ml four-necked bottle, add 70 parts of white oil, 5 parts of n-pentanol, 5 parts of Span80, and then add the water phase (containing 4 parts of distilled water, 3.6 parts of acrylamide, 0.5 parts of macromolecular emulsifier A 1 , 0.0144 parts of tetrasodium ethylenediaminetetraacetic acid, 0.8 parts of ammonium bromide); through N 2 Exhaust oxygen for 0.5 hours, add 0.003 parts of azobisisobutyronitrile, heat to 70°C to initiate the reaction, and then add 70 parts of monomers, (50% aqueous solution, acrylamide: methacryloyloxyethyl dimethyl ethyl Ammonium bromide = 10:1, pass N before use 2 0.5 hour), continue to react for 10 hours after the addition of the monomer. The uniform and stable microemulsion product obtained by the reaction.

Embodiment 3

[0051] Into a 250ml four-necked bottle, add 70 parts of white oil (a mixture of straight chain hydrocarbons and cyclic hydrocarbons), 5 parts of n-pentanol, 4 parts of distilled water, 3.6 parts of acrylamide, 0.0144 parts of ethylenediaminetetraacetic acid tetra Sodium salt, 0.8 parts of ammonium bromide, 0.36 parts of macromolecular emulsifier A 2 ; pass N 2 Add 0.0003 parts of azobisisobutyronitrile in 0.5 hours, heat to 70°C to initiate the reaction, keep the temperature at 60°C for reaction, add 70 parts of monomer (50% aqueous solution, acrylamide: methacryloyloxyethyl dimethyl ethyl Ammonium bromide = 10:1, through N 2 0.5 hours), continue to react for 10 hours after the addition of the monomer. The obtained uniform and stable microemulsion product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com