Micro-mist dust suppression method based on coal cutter cutting dust sources

A technology for a shearer and a shearer drum is applied in the field of micro-mist dust suppression based on the cutting of dust sources by a shearer, and can solve problems such as abnormal extrusion, damage to the external spray system, and easily wet clothes, etc. Improve the suppression capability, use the effect of reliable and efficient capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make those skilled in the art better understand the present invention, the present invention will be further clearly and completely described below with reference to the accompanying drawings and the embodiments. It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict.

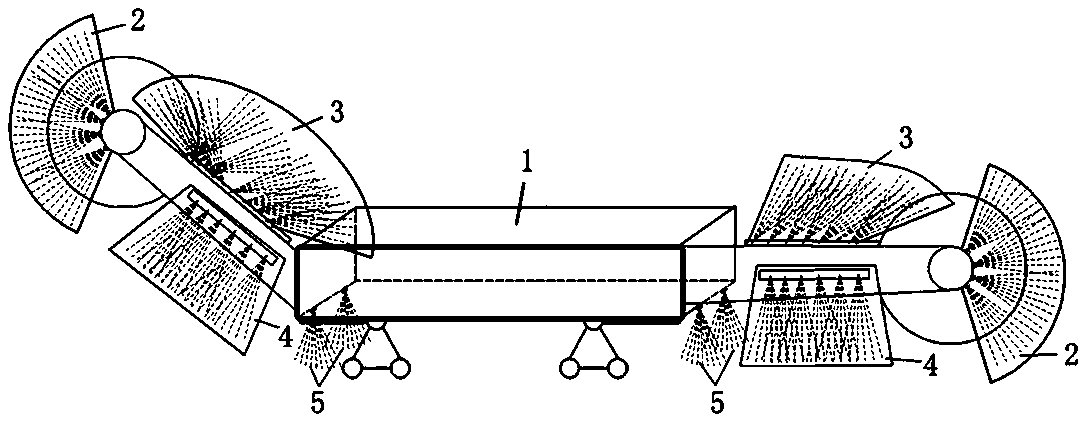

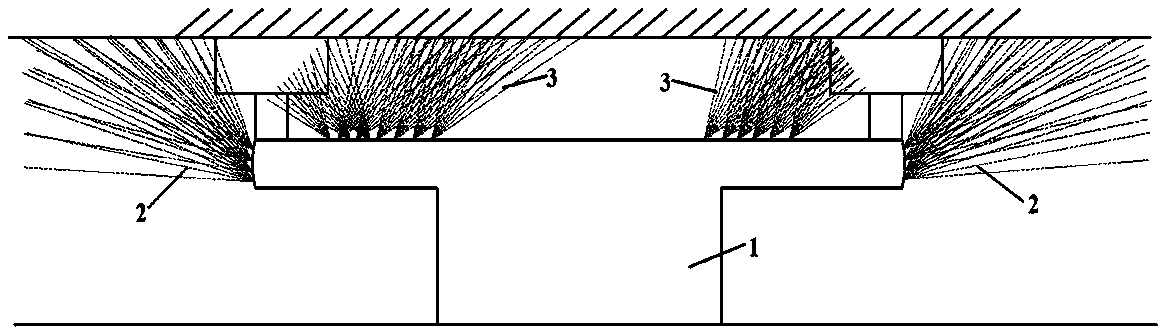

[0027] like figure 1 and figure 2 As shown in the figure, a micro-fog dust suppression method based on cutting dust source by shearer, for different dust sources generated by shearer cutting dust, different spray modules are installed on corresponding parts of shearer 1 to prevent each The dust source is treated for dust suppression. The spray module is composed of several nozzles. The number of nozzles is set according to the actual situation, and the nozzles are installed in an embedded way, so that they have a certain anti-smashing function. The specific technical solutions are as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com