Optical power automatic calibration system and method

An automatic calibration, optical power technology, applied in the field of optical communication, can solve the problems of inconvenient operation, cumbersome test process, multiple devices, etc., to achieve the effect of small space occupation and shortening of manual adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

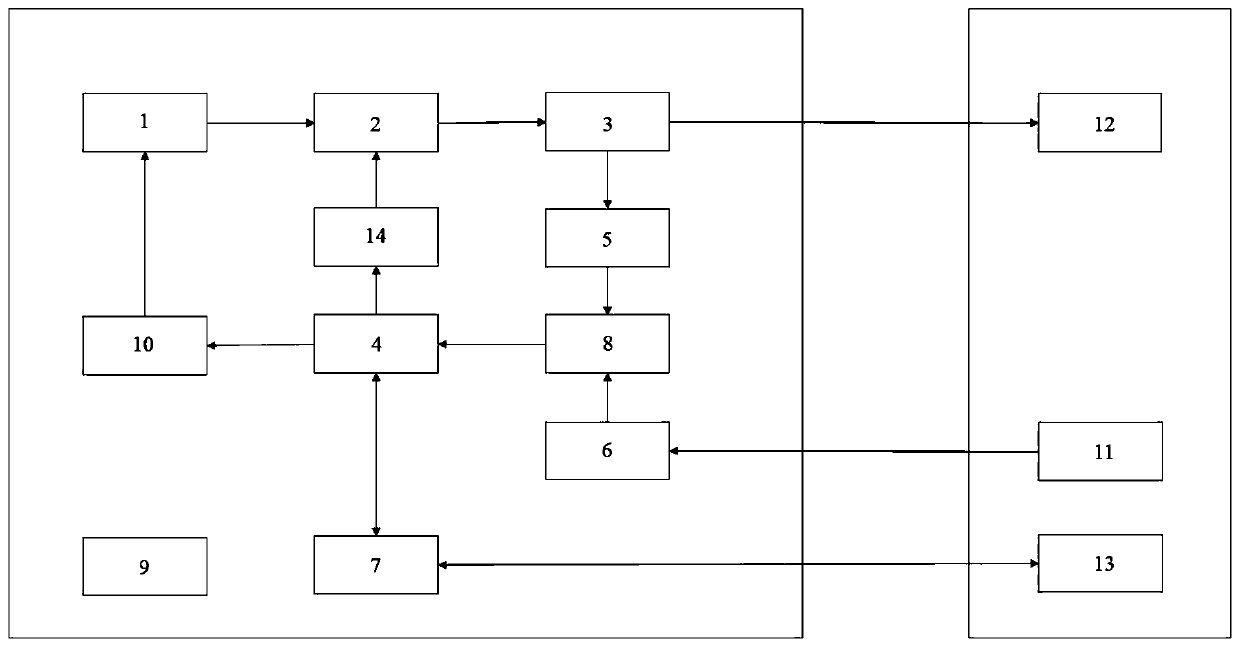

[0051] A new type of optical power automatic calibration system proposed by the present invention, its structure is as follows figure 1 As shown, it consists of a light source module 1, an electrical modulation attenuator 2, a beam splitter with one input and two outputs 3, a micro control unit MCU 4, an output photodetector 5, an input photodetector 6, a system serial interface 7, and ADC analog-to-digital conversion Module 8, temperature detection control circuit 9, current drive circuit 10, and analog voltage control circuit 14 are composed.

[0052] The optical output terminal 11 of the module to be tested is connected to the input photodetector 6, the input photodetector 6 is connected to the micro control unit MCU4 through the ADC analog-to-digital conversion module 8, and the first end of the micro control unit MCU4 is connected to the temperature detection control circuit 9, The second end of the micro control unit MCU4 is connected to the current drive circuit 10 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com