Capacitance tomography sensor and system

A capacitance tomography and sensor technology, applied in the field of sensors, can solve the problems of non-reusable, inconvenient replacement, maintenance, and difficult sensor installation, etc., and achieve the effects of reducing test costs, convenient manufacturing process, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

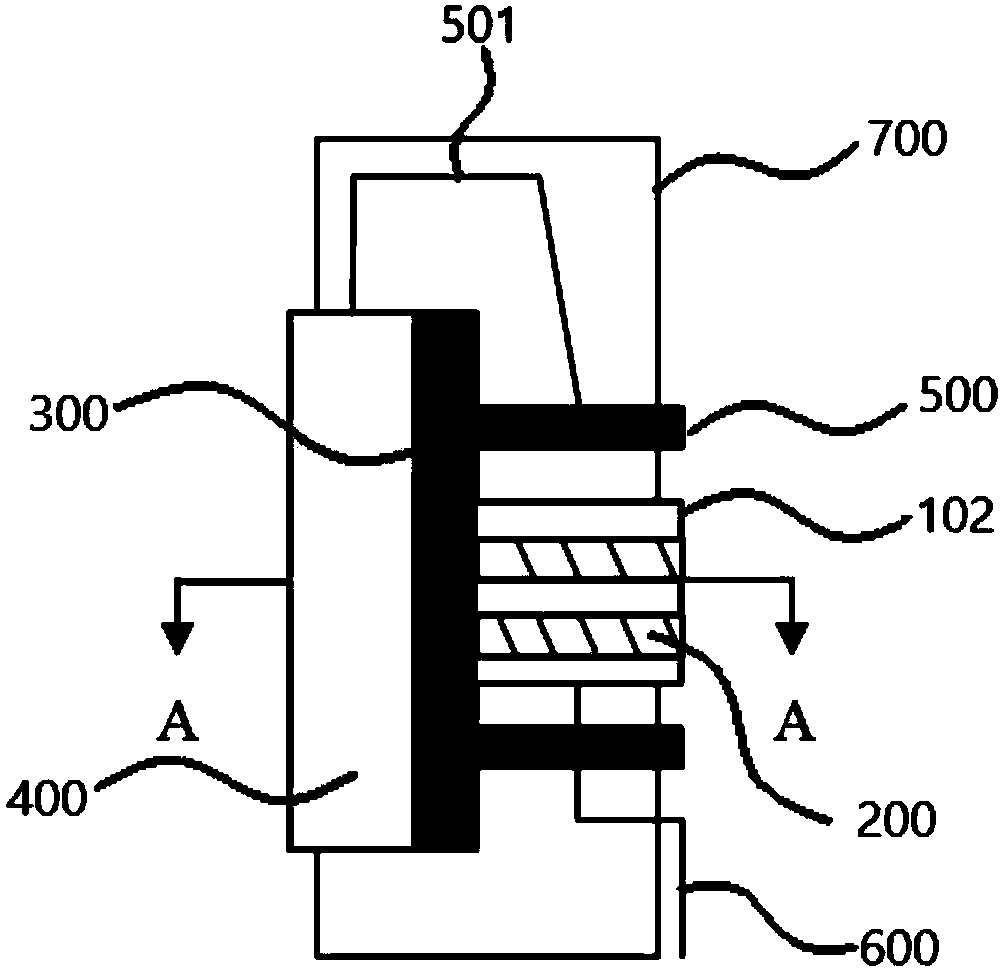

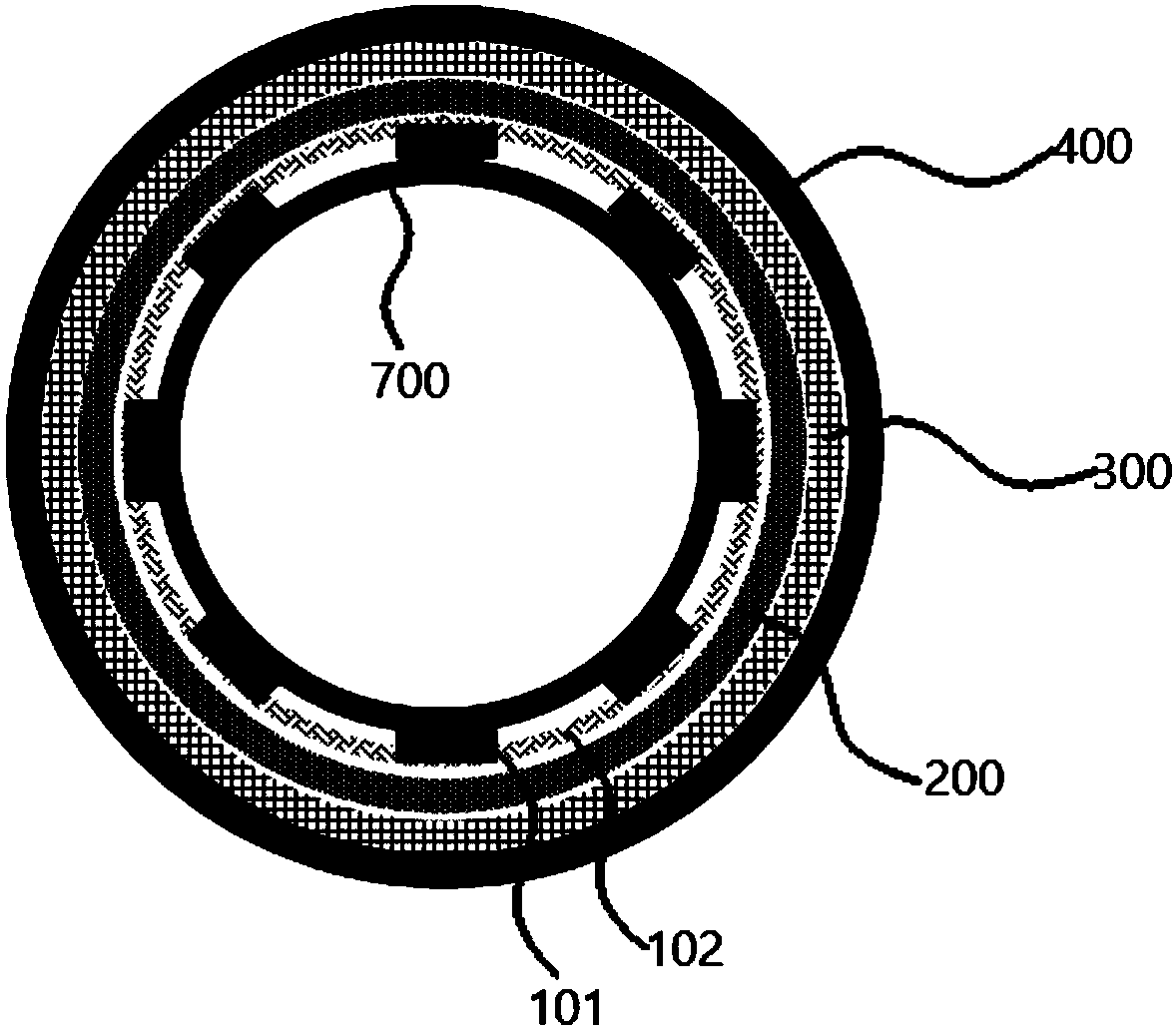

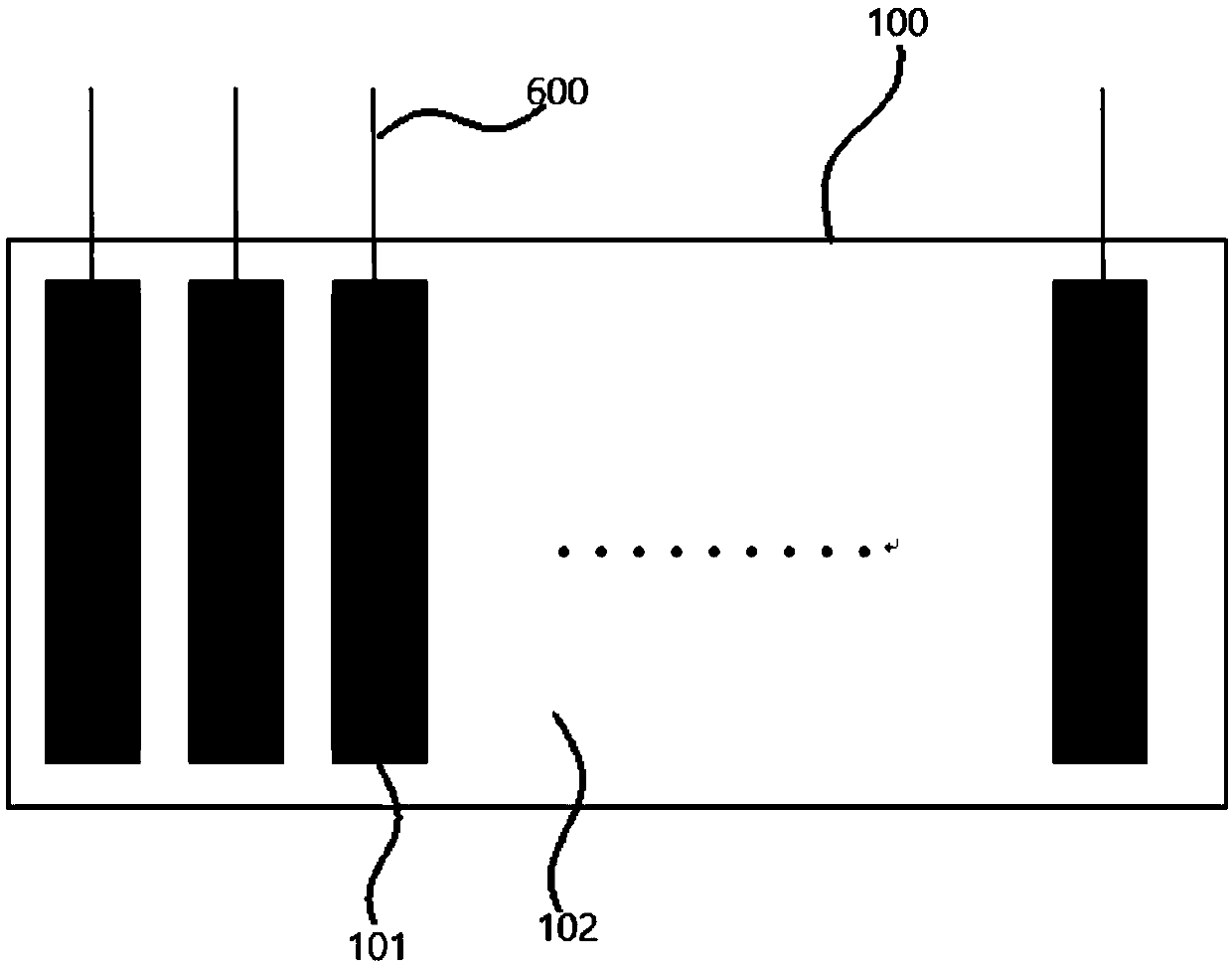

[0034] figure 1 It is a schematic structural diagram of an electrical capacitance tomography sensor in an embodiment of the present application, figure 2 for figure 1 A transverse cross-sectional view of the electrical capacitance tomography sensor shown in A-A direction, image 3 It is a schematic structural diagram of a flexible electrode assembly in an electrical capacitance tomography sensor in an embodiment of the present application, Figure 4 It is a schematic structural diagram of a fixing member in an embodiment of the present application, combined below Figure 1~4 The implementation of this embodiment will be described in detail.

[0035] The electrical capacitance tomography sensor provided in this application includes a flexible electrode assembly 100, a fixing member 200, an insulating isolation layer 300, and an outer shield 400;

[0036] The flexible electrode assembly 100 includes an array electrode 101 and a flexible carrier 102, and the array electrode ...

Embodiment 2

[0063] The following describes the fabrication process of the electrical capacitance tomography sensor provided by the present application.

[0064] In this embodiment, the arrayed electrodes 101 are evenly pasted on the flexible carrier 102 at fixed intervals, and the single electrodes of the arrayed electrodes 101 are not in contact with each other. The flexible carrier 102 is wound on the outer surface of the measured object 700, so that the array distribution electrodes 101 are attached to the surface of the measured object 700 and evenly distributed around the measured area. Fix the shaft-end shielding electrode 500 on the surface of the measured object 700 at the upper and lower axial ends of the array electrode 101, and use the fixing member 200 to fix the flexible carrier 102 and the array electrode 101 on the outer surface of the measured object 700 to prevent measurement During the process, the array electrode 101 moves. The outer side of the flexible carrier 102 an...

Embodiment 3

[0068] This embodiment provides a capacitance tomography system, including a signal acquisition system, a computer imaging display system, and any of the capacitance tomography sensors described above. The capacitance tomography sensor is connected to the signal acquisition system through a signal output line 600, so that The signal acquisition system is connected with the computer imaging display system.

[0069] In this application, the signal transmission line 600 transmits the electrode signal detected by the array electrode 101 to the signal acquisition system, and then transmitted to the computer imaging display system through the data acquisition card in the signal acquisition system to complete image reconstruction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com