A method of 3D printing personalized periodontal tissue regeneration materials

A periodontal tissue regeneration and 3D printing technology, applied in tissue regeneration, additive processing, medical science, etc., can solve problems such as infection, prolonging operation time, and lack of retention, so as to promote proliferation and differentiation, simplify surgical procedures, The effect of simplifying the surgical phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described below with reference to the embodiments.

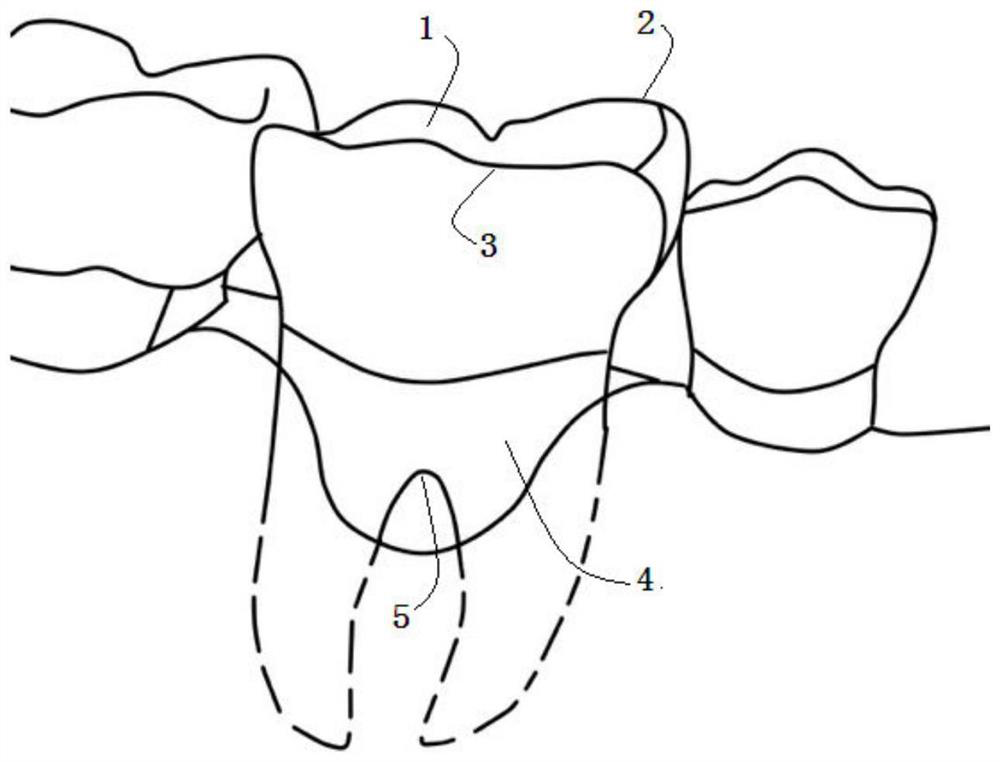

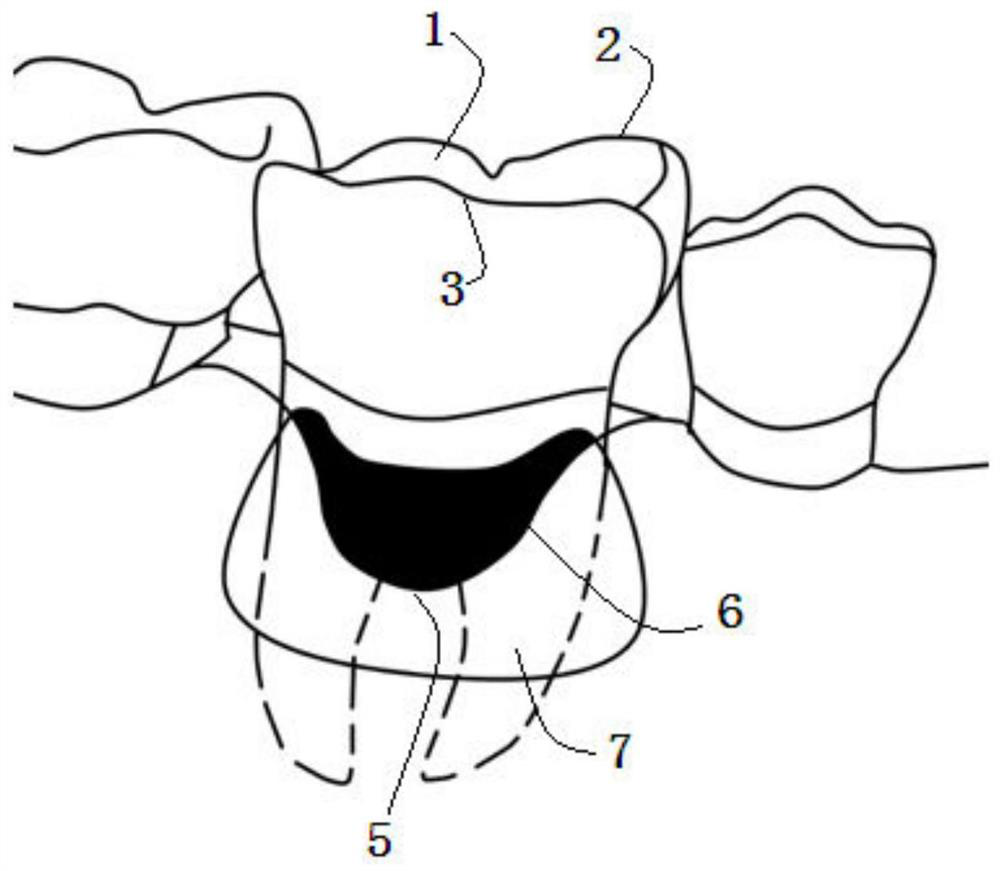

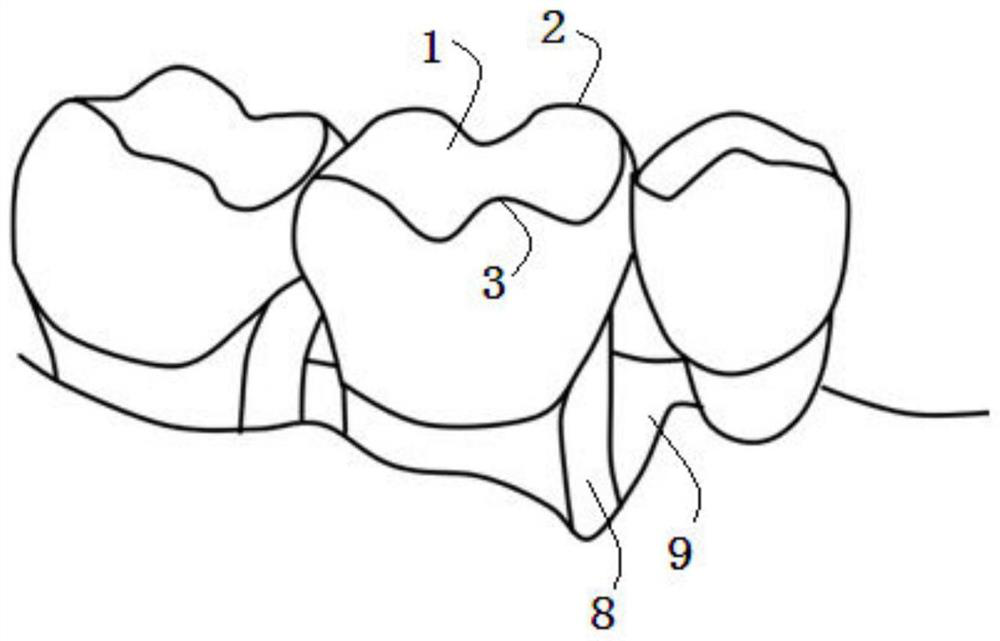

[0027] The invention combines the preoperative CBCT three-dimensional projection technology, and designs a personalized integrated implant material for periodontal guided tissue regeneration according to the shape of the dental bone defect, so as to achieve the required filling after debridement. Bone tissue and membranous tissue that blocks the growth of gingival epithelium. This individual integrated material can have good bonding and retention with the periodontal tissue defect area, maintain space and block the entry of epithelium. Growth factors can be added to the material as needed , suture the gums directly after filling, simplify the operation process and improve the operation efficiency. The present invention can provide an integrated bone graft material, using 3D printing degradable magnesium particles, the implanted shape can be accurately analyzed by the three-dimensional mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com