Mold filling device for ferrite soft magnetic core production

A soft magnetic core, ferrite technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of manpower consumption and low efficiency, and achieve the effect of improving efficiency, avoiding air bubbles, and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

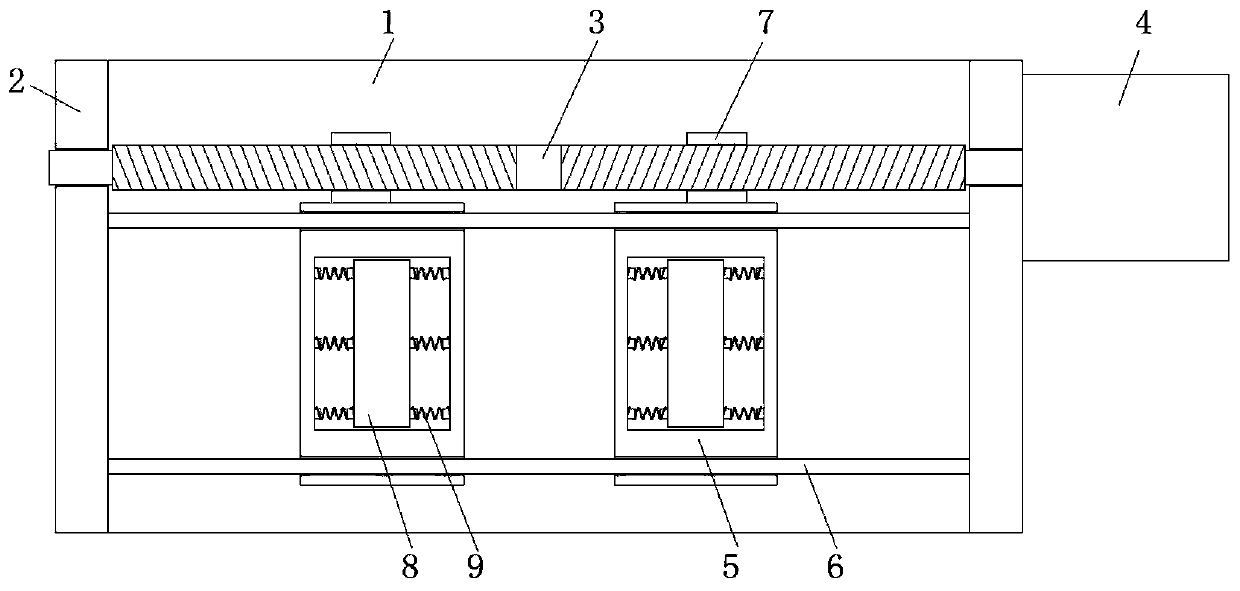

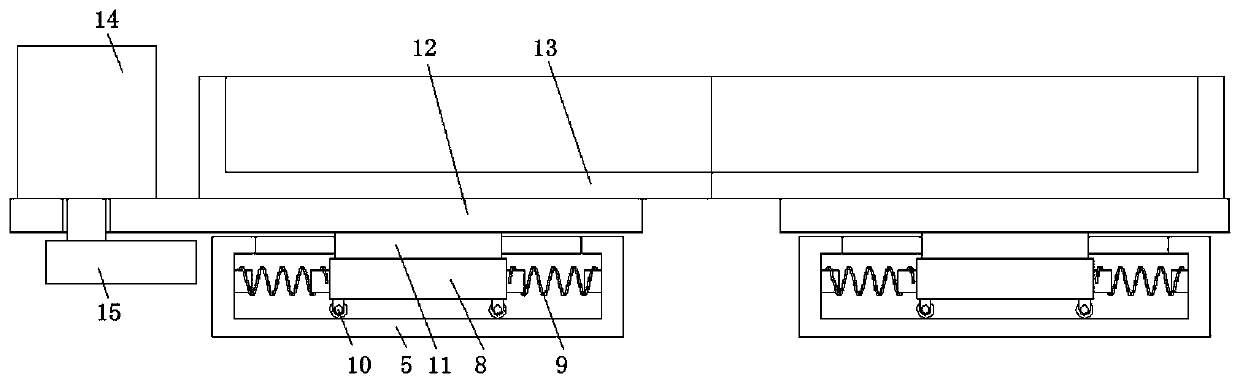

[0022] refer to Figure 1-4 , a mold filling device for ferrite soft magnetic core production, comprising a working base plate 1, both ends of the top side of the working base plate 1 are fixedly connected with vertical plates 2, and two-way threaded rods 3 are arranged for rotation between the vertical plates 2, vertically One side of the plate 2 is fixed with a motor 4 by bolts, the output shaft of the motor 4 is connected to the two-way threaded rod 3 in transmission, and a sliding table 5 and a track bar 6 are also arranged between the two vertical plates 2, and the track bar 6 The two ends are fixedly connected to one side of the vertical plate 2 respectively. There are two sliding tables 5, and both of them are provided with slide holes and are all slidably sleeved on the outside of the rod body of the track rod 6. The outside of the rod body of the two-way threaded rod 3 is provided with two ends. The threaded grooves with opposite textures are threadedly connected with...

Embodiment 2

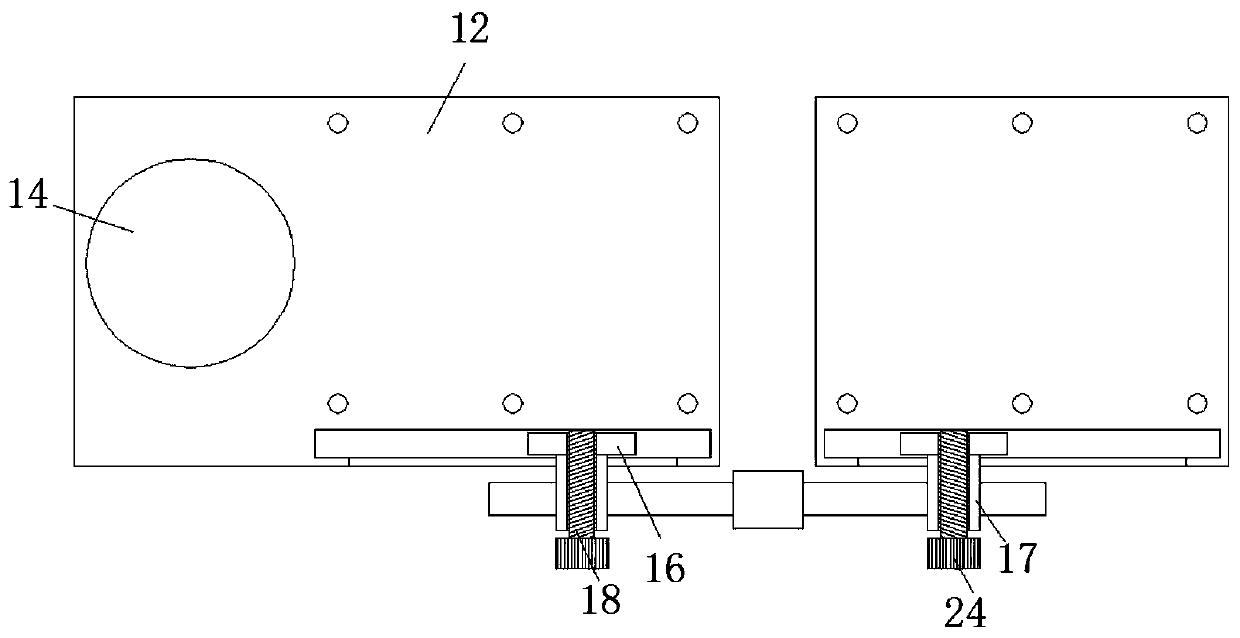

[0026] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, one end of the fixed threaded column 18 is fixedly connected with a knob 24 , and the knob 24 is provided with anti-slip grooves.

[0027] In this embodiment, the setting of the anti-slip grooves is convenient for people to turn the knob 24. By turning the knob 24, people can make the side slide plate 16 and the threaded force receiving cylinder 17 maintain a relatively stable position with the installation table 12, and when installing molds of different lengths After the body 13 is separated, the initial position of the threaded force receiving cylinder 17 is different, so it needs to be adjusted so that the distance to push the swash plate 23 upward is effective.

Embodiment 3

[0029] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, rollers 10 are provided at the four corners of the bottom of the inner slide 8 .

[0030] In this embodiment, the arrangement of the rollers 10 effectively reduces the frictional force and energy consumption.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap